Heavy Dull Aluminum Baking Sheets - Continuous Casting Aluminum Circle for Pot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

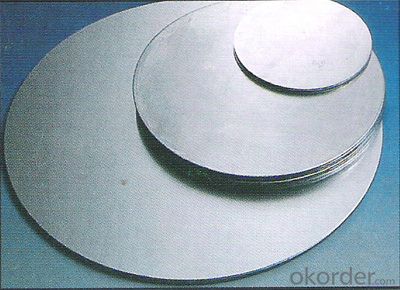

1.Structure of Continuous Casting Aluminium Circle for Pot

Continuous Casting Aluminium Circle for Pot is one semi-finished aluminium material. This Aluminium Circle is widly used to produce aluminium pot, especially for spinning The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Circle for Pot

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Diameter | Weight |

| AA1050 | H14 | 0.2MM-2MM | 100MM-1000MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can 101 aluminum sheets be used in the production of decorative panels?

- Yes, 101 aluminum sheets can be used in the production of decorative panels. 101 aluminum is a commercially pure aluminum alloy known for its excellent formability and corrosion resistance. These characteristics make it suitable for various applications, including decorative panels. The aluminum sheets can be easily shaped, cut, and fabricated to create intricate designs and patterns for decorative purposes. Additionally, the corrosion resistance of 101 aluminum ensures that the panels will maintain their appearance over time, even in outdoor or high-moisture environments.

- Q: Can aluminum sheets be easily shaped or bent into desired forms?

- Yes, aluminum sheets can be easily shaped or bent into desired forms due to their malleability and ductility.

- Q: Can aluminum sheets be anodized for aesthetic purposes?

- Aluminum sheets have the ability to undergo anodization for the purpose of aesthetics. Anodization is an electrochemical procedure that forms a protective oxide layer on the surface of the aluminum. This layer has the potential to be colored in a variety of shades, thus offering a wide range of aesthetic possibilities. Anodized aluminum sheets are highly sought after in the field of architecture, particularly for constructing facades, due to their enduring and visually pleasing appearance. Furthermore, the anodized layer bolsters the aluminum's resistance to corrosion and wear, making it suitable for both indoor and outdoor applications. Moreover, anodized aluminum sheets can be subjected to additional processes like etching or laser engraving, enabling the creation of intricate designs and patterns.

- Q: How do you prevent galvanic corrosion when using aluminum sheets with other metals?

- To prevent galvanic corrosion when using aluminum sheets with other metals, there are several measures that can be taken: 1. Use a protective coating: Applying a protective coating, such as paint or anodizing, on the aluminum surface can create a barrier between the aluminum and other metals, preventing direct contact and reducing the risk of galvanic corrosion. 2. Insulate the metals: Placing a non-conductive insulating material, such as rubber or plastic, between the aluminum and other metals can help isolate them and prevent galvanic corrosion. 3. Choose compatible metals: Selecting metals that are less prone to galvanic corrosion when in contact with aluminum can reduce the risk. For example, stainless steel, titanium, or other corrosion-resistant alloys are often preferred when working with aluminum sheets. 4. Use dielectric materials: Inserting a dielectric material, such as nylon or Teflon washers, between the aluminum and other metals can act as a barrier and inhibit the flow of electrical current, thereby preventing galvanic corrosion. 5. Control the environment: Avoiding environments with high moisture levels or extreme temperature variations can help reduce the likelihood of galvanic corrosion. Proper ventilation and moisture control can also play a significant role in preventing this type of corrosion. It is important to note that the best preventive measures may vary depending on the specific application and the types of metals involved. Consulting with a materials engineer or corrosion specialist can provide valuable guidance in selecting the most appropriate strategies to prevent galvanic corrosion in a particular scenario.

- Q: Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable and ductile metal, which means it can be easily shaped and bent without fracturing or cracking. This property makes aluminum an ideal material for various applications, including the manufacturing of aircraft, automobiles, and household items. The flexibility of aluminum sheets allows for the creation of intricate designs and complex shapes, making it a highly versatile material. However, it is important to note that the thickness and grade of the aluminum sheet can influence its bendability. Thicker sheets may require more force and specialized tools to achieve the desired bend, while softer grades of aluminum may be more easily bent.

- Q: Can aluminum sheets be used for reflective insulation?

- Yes, aluminum sheets can be used for reflective insulation. Aluminum is highly reflective and has good thermal conductivity, making it an excellent choice for reflecting heat and reducing heat transfer. When used as insulation, aluminum sheets can reflect heat away from the surface, preventing it from entering or escaping the desired area. This can help in maintaining a comfortable temperature inside a building or protecting sensitive equipment from extreme heat or cold. Additionally, aluminum sheets are lightweight and easy to install, making them a popular choice for reflective insulation applications.

- Q: What is the maximum sheet size available for aluminum sheets?

- The maximum sheet size available for aluminum sheets varies depending on the specific supplier and manufacturer. However, commonly available sheet sizes for aluminum range from 4 feet by 8 feet (1219mm x 2438mm) to 5 feet by 10 feet (1524mm x 3048mm).

- Q: Are the aluminum sheets suitable for manufacturing window frames?

- Yes, aluminum sheets are suitable for manufacturing window frames.

- Q: Are aluminum sheets suitable for use in electrical applications?

- Yes, aluminum sheets are suitable for use in electrical applications. Aluminum is an excellent conductor of electricity, and its high conductivity allows for efficient transmission of electrical current. Aluminum sheets are commonly used in electrical applications such as power transmission lines, electrical wiring, and electrical enclosures. Additionally, aluminum is lightweight, which makes it easier to handle and install. It is also resistant to corrosion, which ensures long-term durability and reliability in electrical systems. However, it is important to note that aluminum has a lower conductivity compared to copper, so it may require larger gauge sizes to compensate for this difference. Overall, aluminum sheets are a viable and cost-effective option for various electrical applications.

- Q: I recently moved into a 1975 house with aluminum wiring. I will be going through and checking/replacing all receptacles and switches with CO/ALR rated ones as I don't have a budget right now to rewire the house. I am wondering if I should be checking all of the ceiling lights as well as some of them would be very difficult to access. Are lights as big a concern with aluminum connections as receptacles? I am sure some of the lights are newer and would have copper wire connected to the aluminum. Should I be concerned about the type of wire nuts used here?Anything else that I should be checking?

- There's no problem with aluminum wiring that would require you to rewire your house as long as the proper wire gauge was used. You should replace all of the receptacles and switches with ones rated CO/AL. For lighting, replace the wirenuts with ones rated CO/AL and you'll be fine. From what I remember, Aluminum has a higher resistance than copper so it requires 1 size larger conductors. Aluminum also oxidizes faster than copper. If you have aluminum wires in your panel you should turn the main service disconnect off and put some de-oxidizer (you can find it at home improvement stores in the electrical section) where the wire lug is. This oxidation can make a bad connection causing you to lose voltage as the resistance goes up raising the amperage. This will generate more heat. Aluminum also... well its hard to explain... A/C current cycles its power in a sin wave, it causes the wire to vibrate. You will have to tighten all of the lugs on your electric panel periodically. The CO/AL wirenuts and receptacles/switches help prevent the vibration from loosening the connections causing a short and possibly a shock hazard or even a fire.

Send your message to us

Heavy Dull Aluminum Baking Sheets - Continuous Casting Aluminum Circle for Pot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords