Aluminum Foil Sheets Continuous Casting Aluminium Circle for Spinning Pan

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

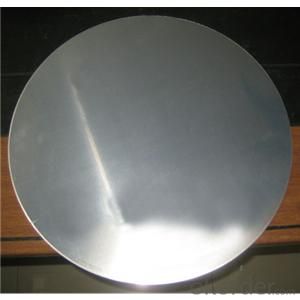

1.Structure of Continuous Casting Aluminium Circle for Spinning Pan

Continuous Casting Aluminium Circle for Spinning Pan is one semi-finished aluminium material. This Aluminium Circle is widly used to produce aluminium pot, especially for spinning The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Circle for Spinning Pan

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Diameter | Weight |

| AA1050 | H14 | 0.2MM-2MM | 100MM-1000MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheets be used for cookware?

- Yes, aluminum sheets can be used for cookware. Aluminum is a popular material for cookware due to its excellent heat conductivity and lightweight properties. Aluminum sheets are often used as the base or core material in the construction of cookware, such as pots, pans, and baking sheets. They are typically coated with a nonstick or ceramic layer for added durability and ease of use. However, it is important to note that pure aluminum is reactive with certain acidic or alkaline foods, which can cause a metallic taste or discoloration. To prevent this, most aluminum cookware is anodized or coated to create a barrier between the food and the aluminum surface. Overall, aluminum sheets are a versatile and commonly used material for cookware in both professional and home kitchens.

- Q: Can aluminum sheets be used for decorative wall panels?

- Yes, aluminum sheets can be used for decorative wall panels. Aluminum is a versatile material that offers a wide range of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it suitable for both interior and exterior applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for endless design possibilities. Additionally, aluminum can be powder-coated or anodized to enhance its appearance and provide additional protection against wear and tear. Whether it's for residential or commercial spaces, aluminum sheets can add a modern and stylish touch to any wall, making them a popular choice for decorative wall panels.

- Q: Can aluminum sheets be laminated?

- Indeed, it is possible to laminate aluminum sheets. Lamination involves the fusion of multiple layers to form a composite material that exhibits improved properties. Aluminum sheets, for instance, can undergo lamination with diverse substances like plastics, adhesives, or even alternative metals. This method has the potential to enhance the strength, durability, as well as the thermal and electrical conductivity of the aluminum sheets. The resultant laminated aluminum sheets find widespread application in numerous industries, including construction, automotive, aerospace, and packaging. This utilization is driven by the ability of the amalgamation of distinct materials to confer tailored characteristics suitable for specific purposes.

- Q: What is the maximum sheet size available for aluminum sheets?

- The maximum sheet size available for aluminum sheets can vary depending on the manufacturer and specific application. However, in general, the standard maximum sheet size for aluminum sheets is typically 4 feet by 12 feet (48 inches by 144 inches). This size is commonly used in various industries such as construction, automotive, and aerospace. It is important to note that larger sizes may be available upon request from certain suppliers, but these may come with additional costs and considerations.

- Q: What are the safety concerns to be aware of when handling aluminum sheets?

- <p>When working with aluminum sheets, there are a few safety concerns to consider. First, aluminum dust can be a respiratory hazard, so it's important to use proper ventilation and personal protective equipment like masks. Second, sharp edges can cause cuts; always handle aluminum sheets with gloves and proper tools. Additionally, aluminum is a good conductor of electricity, so avoid contact with live electrical wires. Lastly, when cutting or shaping aluminum, eye protection is crucial due to the risk of flying debris. Always follow safety guidelines specific to your workplace and the tools you are using.</p>

- Q: What is the typical thermal expansion coefficient of aluminum sheets?

- The typical thermal expansion coefficient of aluminum sheets is around 23.1 x 10^-6 per degree Celsius. This means that for every degree Celsius increase in temperature, the length of an aluminum sheet will increase by approximately 23.1 millionths of its original length. It is important to note that this value can vary slightly depending on the specific alloy and processing conditions of the aluminum sheet.

- Q: Can aluminum sheets be used for heat exchangers?

- Yes, aluminum sheets can be used for heat exchangers. Aluminum is a highly efficient conductor of heat, making it an ideal material for heat exchangers. Its high thermal conductivity allows for excellent heat transfer between fluids, resulting in efficient heat exchange. Additionally, aluminum sheets are lightweight, corrosion-resistant, and have good mechanical properties, further contributing to their suitability for heat exchanger applications.

- Q: What rules or guidelines exist for using recycled aluminum sheets in construction projects?

- <p>Yes, there are regulations and guidelines regarding the use of recycled aluminum sheets in construction. These often include standards for material quality, safety, and environmental impact. The American Society for Testing and Materials (ASTM) and the Aluminum Association provide specifications for recycled aluminum alloys used in construction. Compliance with building codes and local regulations is essential. Additionally, recycled aluminum must meet performance and safety standards equivalent to those of new materials. It's crucial to check with local building authorities and consult the latest industry standards to ensure compliance when using recycled aluminum in construction.</p>

- Q: What are the applications of aluminum sheet?

- Due to their unique properties and versatility, aluminum sheets have a wide range of applications. Some common uses include: 1. Construction: In the construction industry, aluminum sheets are widely utilized for roofing, siding, and cladding purposes. Their lightweight nature allows for easy handling and installation, while their corrosion resistance ensures durability over time. 2. Transportation: Aluminum sheets play a crucial role in the automotive industry by being extensively used in manufacturing vehicle bodies, panels, and structural components. Their high strength-to-weight ratio helps reduce overall vehicle weight, leading to increased fuel efficiency and improved performance. 3. Packaging: Within the packaging industry, aluminum sheets are commonly employed in the production of cans, foils, and containers. Aluminum foils, in particular, are utilized for food packaging as they provide a protective barrier against moisture, light, and oxygen, ensuring the freshness and safety of packaged products. 4. Electrical: The electrical industry relies on aluminum sheets for manufacturing power transmission lines, busbars, and electrical enclosures. Their excellent electrical conductivity aids in the efficient transmission of electricity, while their corrosion resistance allows for longevity in outdoor applications. 5. Marine: The marine industry extensively utilizes aluminum sheets for manufacturing boat hulls, decks, and superstructures. Their resistance to corrosion from saltwater makes them ideal for marine applications, and their lightweight nature helps reduce overall vessel weight. 6. Aerospace: In the aerospace industry, aluminum sheets are widely used for manufacturing aircraft and spacecraft components. Their high strength-to-weight ratio and excellent thermal conductivity make them suitable for applications where weight reduction and heat dissipation are critical. 7. Heat exchangers: Aluminum sheets are crucial in the manufacturing of heat exchangers, such as radiators and condensers. Their high thermal conductivity allows for efficient heat transfer, making them ideal for applications that require heat exchange. 8. Decorative: Aluminum sheets also find common use in interior design and architectural applications for decorative purposes. They can be easily shaped, bent, and formed into various designs, adding a modern and aesthetic appeal to buildings and interiors. In summary, aluminum sheets are extensively utilized in various industries due to their lightweight nature, corrosion resistance, high strength-to-weight ratio, and excellent thermal conductivity.

- Q: What are the advantages of using aluminum sheets in the furniture industry?

- Aluminum sheets have numerous benefits when utilized in the furniture industry. To begin with, their lightweight composition makes them easy to transport and install, reducing the overall weight of furniture and simplifying assembly or rearrangement. Moreover, their lightweight nature allows for increased design flexibility, enabling manufacturers to create intricate and distinctive furniture pieces. Additionally, aluminum sheets possess exceptional durability and corrosion resistance. Unlike materials such as wood or steel, aluminum does not rust or deteriorate over time, making it suitable for both indoor and outdoor furniture. This durability ensures that furniture constructed from aluminum sheets has a longer lifespan, reducing the need for frequent replacements. Furthermore, aluminum sheets possess high malleability, facilitating effortless shaping and customization. This design flexibility empowers furniture manufacturers to fabricate pieces with intricate patterns, curves, and contours. Aluminum sheets can be easily molded into various shapes and sizes, providing limitless possibilities for creativity and innovation in furniture design. Moreover, aluminum sheets require minimal maintenance. They are easy to clean and necessitate minimal upkeep, saving time and effort for both manufacturers and consumers. Consequently, aluminum sheets are an ideal choice for furniture in high-traffic areas or public spaces where regular cleaning is necessary. Furthermore, aluminum sheets contribute to environmental sustainability. Aluminum is a highly recyclable material, allowing furniture made from aluminum sheets to be easily recycled at the end of its life cycle. This reduces the environmental impact and promotes sustainability within the furniture industry. Lastly, aluminum sheets possess excellent thermal conductivity. Furniture constructed from aluminum sheets can efficiently absorb and dissipate heat, providing comfort to users. For applications such as outdoor furniture or items exposed to sunlight, aluminum sheets can prevent overheating and maintain a comfortable temperature. In conclusion, the advantages of using aluminum sheets in the furniture industry encompass their lightweight composition, durability, malleability, low maintenance, environmental friendliness, and excellent thermal conductivity. These properties have made aluminum sheets a popular choice among furniture manufacturers, enabling them to produce high-quality, innovative, and long-lasting furniture pieces.

Send your message to us

Aluminum Foil Sheets Continuous Casting Aluminium Circle for Spinning Pan

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords