Denver Aluminum Sheets - Continuous Casting Aluminum Circle for Spinning

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

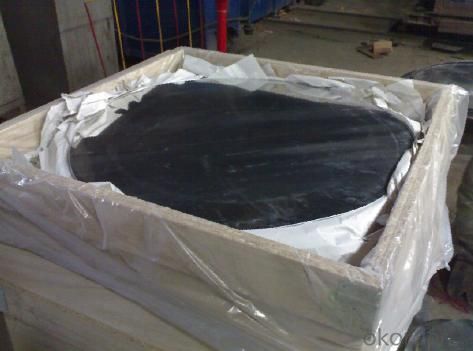

1.Structure of Continuous Casting Aluminium Circle for Spinning

Continuous Casting Aluminium Circle for Spinning is one semi-finished aluminium material. Aluminium Circle is widly used cookware, for example, aluminium pot, aluminium pan, aluminium cup ect. Our aluminium circle are widly exported to African market. We export more than 2000 tons every month. We can assure the breakage rate below 5%. Extra breakage will be responsible by our company.

2. Main features of Continuous Casting Aluminium Circle for Spinning

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Thickness | Diameter | Weight | Style |

| AA1100 | 0.2MM-2MM | 100MM-1000MM | 2 TONS | Spinning |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 2 tons.

- Q: To rephrase- in our physics class we found that a simple bar magnet wouldn't attract to an aluminum gutter nail, but our teacher told us to find out whether or not any magnet could lift up the aluminum material. If you answer please give a reference or source, or at least an idea on how to go about researching this, all help appreciated, thanks and God Bless!

- Magnet And Aluminum

- Q: I am doing a project on Aluminum it has 13 protons just to make sure everyones on the same page. How much of it is left or exsits? Also how does it behave?

- Aluminium is one of the most abundant Element on earth, ranking 3rd in the crust, second only to oxygen and silicon. And it is eminently recyclable. However, many minerals containing aluminium are not economically exploitable.

- Q: Can aluminum sheets be bent into complex shapes?

- Yes, aluminum sheets can be bent into complex shapes due to their malleability and ductility. With the appropriate tools and techniques, aluminum sheets can be formed into intricate and customized designs, making them versatile for various applications.

- Q: What are the different types of alloys used for aluminum sheets?

- There are various types of alloys used for aluminum sheets, including 1xxx, 3xxx, 5xxx, and 6xxx series. Each alloy has unique properties and characteristics, making them suitable for different applications. The 1xxx series alloys are pure aluminum, while the 3xxx series alloys contain manganese and exhibit good formability. The 5xxx series alloys have magnesium as the primary alloying element and offer excellent corrosion resistance. Lastly, the 6xxx series alloys are known for their combination of strength, formability, and weldability, with magnesium and silicon as their main alloying elements.

- Q: What is the standard thickness of aluminum sheets used for exterior building applications?

- <p>The typical thickness of aluminum sheets used for building exteriors ranges from 0.7mm to 1.2mm. This range is suitable for applications such as facades, cladding, and roofing. The specific thickness can vary depending on the structural requirements, wind loads, and the overall design of the building. Thicker sheets may be used for more robust structures or in areas with higher wind pressures, while thinner sheets can be used for lighter applications or when a more aesthetically pleasing finish is desired.</p>

- Q: What are the physical properties of aluminum?

- Some physical properties of aluminum include its silvery-white appearance, low density, high thermal conductivity, and good electrical conductivity. It has a melting point of 660.32°C (1220.58°F) and a boiling point of 2519°C (4566°F). Aluminum is also malleable, ductile, and highly corrosion resistant.

- Q: Are aluminum sheets suitable for chemical processing?

- Yes, aluminum sheets are suitable for chemical processing due to their excellent corrosion resistance, high thermal conductivity, and lightweight properties. They can be effectively used for various chemical applications such as containers, piping, and heat exchangers.

- Q: Can the aluminum sheets be used in food or beverage processing industries?

- Indeed, the food and beverage processing industries can utilize aluminum sheets. This non-toxic material is extensively employed in this field owing to its exceptional characteristics. Aluminum sheets boast corrosion resistance, light weight, and commendable thermal conductivity. These attributes render them perfect for a multitude of applications in the food and beverage processing industries, including food packaging, cooking utensils, storage containers, and beverage cans. Furthermore, aluminum proves to be an environmentally friendly choice as it is recyclable, thus amplifying its appropriateness for deployment in these sectors.

- Q: What are the different methods of surface laminating aluminum sheets?

- There are several methods of surface laminating aluminum sheets, including adhesive bonding, roll bonding, and extrusion. Adhesive bonding involves using an adhesive to attach a layer of material onto the surface of the aluminum sheet. Roll bonding involves passing the aluminum sheet through a set of rollers, which bond a layer of material onto the surface. Extrusion involves forcing the aluminum sheet through a die, which applies a layer of material onto the surface. These methods provide different options for achieving surface lamination based on the desired application and requirements.

- Q: What is the color range available for aluminum sheets?

- Aluminum sheets come in a wide range of colors, offering a diverse selection. Standard colors include silver, black, white, bronze, and gold. Furthermore, aluminum sheets can be coated with different finishes, such as anodized, painted, or powder coated, which expands the color options even more. These coatings provide an array of colors, including vibrant shades like red, blue, green, yellow, and many others. Moreover, specialized processes enable the achievement of custom colors, allowing for personalized and unique choices. In summary, the color range for aluminum sheets is extensive and adaptable, meeting different aesthetic preferences and design needs.

Send your message to us

Denver Aluminum Sheets - Continuous Casting Aluminum Circle for Spinning

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords