Aluminum Sheets Iowa - Continuous Casting Aluminum Circle for Kitchen Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

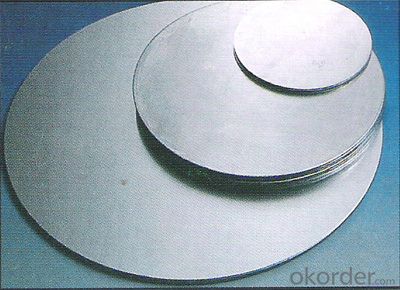

1.Structure of Continuous Casting Aluminium Circle for Kitchen Cookware

Continuous Casting Aluminium Circle for Kitchen Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Circle for Kitchen Cookware

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: I am thinking about getting a MacBook Aluminum or a MacBook white. The Aluminum is 2.0 GhZ and the MacBook White is 2.16 GhZ. which should i get? also i am really wondering if you can upgrade the processors in both MacBooks..... Please give me link if you can. THANKS!!

- The aluminum will definitely be faster than the white one assuming those clock speeds are accurate. The 2.16 is an older model with an early Core 2, slower RAM, and a much slower video card. And you cannot swap the CPU in any of Apple's laptops made over the past decade or so.

- Q: Can aluminum sheet withstand heavy loads?

- Yes, aluminum sheet can withstand heavy loads. Aluminum is known for its high strength-to-weight ratio, making it an excellent choice for applications that require durability and load-bearing capabilities. Aluminum sheets are commonly used in industries such as aerospace, automotive, construction, and marine, where heavy loads are involved. Additionally, aluminum's inherent corrosion resistance further enhances its ability to withstand heavy loads over extended periods. However, it is important to consider the specific grade and thickness of the aluminum sheet, as different alloys and thicknesses have varying load capacities.

- Q: Can aluminum sheets be anodized in different colors?

- Aluminum sheets have the capability to undergo anodization in various colors. Anodization involves an electrochemical procedure that enhances the natural oxide layer on the surface of aluminum. By submerging the aluminum sheet in an electrolyte bath and applying an electric current, a controlled oxidation process takes place, resulting in a thick and long-lasting oxide layer on the surface. Throughout the anodization process, different dyes can be introduced into the electrolyte bath, enabling the aluminum to absorb the dye particles and generate a colored oxide layer. This allows for a wide array of colors to be achieved, including red, blue, green, yellow, and numerous others. Furthermore, the brightness and tone of the color can be regulated by adjusting factors such as the dye concentration and the voltage applied during anodization. The anodized layer that forms on the aluminum sheet not only offers a vibrant and visually appealing appearance but also enhances its resistance to corrosion and durability. This makes anodized aluminum sheets an exceptional choice for architectural, decorative, and industrial applications where customization of color is desired while retaining the inherent advantages of aluminum.

- Q: What is the typical hardness of aluminum sheets?

- The typical hardness of aluminum sheets can vary depending on the specific alloy and tempering process used, but it generally falls within the range of 40-70 on the Rockwell B scale.

- Q: This question asks for the various types of surface treatments or coatings that can be applied to aluminum profiles to enhance their properties or appearance.

- <p>Aluminum profiles can be coated with several types of finishes to improve their aesthetic appeal, durability, and corrosion resistance. The common types include: 1) Anodizing, which creates a protective oxide layer on the aluminum surface; 2) Powder coating, where a dry powder is electrostatically applied and then cured under heat; 3) Electrophoretic coating, a method where charged particles adhere to the aluminum and then harden; 4) PVDF (Polyvinylidene Fluoride) coating, known for its excellent weather resistance and durability; 5) Thermal spraying, where a coating material is melted and sprayed onto the aluminum surface; and 6) Painting, which can be done through various methods such as airless spray or dip coating. Each type of coating serves different purposes and has its own set of advantages and applications.</p>

- Q: just bought a hobart handler 140 (already love it), and was just wondering on what gas to use for aluminum. my welder will be set up for mild steel (75% argon 25% CO2). it would be nice to be able to use this mix with aluminum as well, as it would be easy to just switch spools of wire, but the manual says to use a 100% argon mix when welding with aluminum. will the 25% CO2 make a difference welding aluminum?

- You MUST use 100% Ar for MIG welding aluminum. Molten Al is highly reactive. Al powder is the active ingredient in thermite, for example. It will react with CO2, stripping away the oxygen and creating a nasty mess. Also, you really need a MIG welder with twice as much current output. along the lines of 200-300 amps. 130 amps will not perform well even with a spool gun, and running the weak, prone-to-jamming .030 Al wire. You could try to do it that way, but I would not advise. (There is no way in hell you'd be able to cram wimpy .030 Al wire through a 6 foot traditional welding lead. It'll kink and jam after 5 seconds.) MIG welding aluminum REQUIRES using the high-current, high feed speed, spray transfer mode. Here are some typical parameters: 030 wire, 500 IPM, 22 volts. 120-130 amps. 035 wire, 500 IPM, 23 volts, 150 amps. 045 wire, 400 IPM, 24 volts, 200 amps. EDIT, the guy above me has the right idea. They use electricity to force the reaction between aluminum oxide (dissolved in cryolite) and carbon, producing molten Al and CO2 gas. Normally the reaction would tend to go the other way. Aluminum has a higher affinity for oxygen.

- Q: What are the different types of alloys used for anodized aluminum sheets?

- There are several different types of alloys that can be used for anodized aluminum sheets, each with its own unique properties and applications. Some of the commonly used alloys include: 1. 1000 series alloys: These alloys are primarily made of pure aluminum and are known for their excellent corrosion resistance. They are commonly used for anodized aluminum sheets in various industries, including architecture, automotive, and aerospace. 2. 5000 series alloys: These alloys contain magnesium as the primary alloying element, which provides enhanced strength and excellent weldability. They are often used for anodized aluminum sheets in applications that require high strength and resistance to atmospheric corrosion. 3. 6000 series alloys: This series of alloys is known for its excellent combination of strength, extrudability, and corrosion resistance. The most commonly used alloy in this series for anodized aluminum sheets is 6061, which is widely used in structural components, marine applications, and consumer electronics. 4. 7000 series alloys: These alloys are known for their exceptional strength and are typically used in applications that require high-performance materials. The most common alloy in this series for anodized aluminum sheets is 7075, which is widely used in aerospace and defense industries. 5. 2000 series alloys: These alloys are primarily used in applications that require high strength and excellent fatigue resistance. They are commonly used in the aerospace industry for anodized aluminum sheets. It's important to note that the choice of alloy for anodized aluminum sheets depends on the specific requirements of the application, including desired strength, corrosion resistance, and other mechanical properties.

- Q: What type of aluminium sheet is a food grade?

- Pure aluminum, alloy aluminum can be. However, the majority of pure aluminum. Used by customers.

- Q: 3003H24 alloy aluminum plate refers to what kind of aluminum plate?

- Attached: O status: fully annealed to obtain the lowest strength of the processing products. 8 state: hard working state (9)To sum up: 3003 refers to the aluminum manganese alloy, H24 represents the process of rolling, through incomplete annealing to achieve the specified strength, hardness of an aluminum substrate. In addition to the 5 first series of aluminum magnesium alloy used in aluminum plate, the other 4 prefix silicon as the main alloying elements in zinc series, as the elements of the 7 prefix series.

- Q: Can aluminum sheets be used for food display cases?

- Yes, aluminum sheets can be used for food display cases. Aluminum is a popular choice for food display cases due to its exceptional strength, durability, and resistance to corrosion. Additionally, aluminum is lightweight, making it easier to handle and transport the display cases. Its clean, sleek appearance also enhances the presentation of the food items, making it an ideal material for showcasing various food products. Moreover, aluminum is non-toxic and does not react with food, ensuring the safety and hygiene of the displayed items. Overall, aluminum sheets are a suitable and practical choice for constructing food display cases.

Send your message to us

Aluminum Sheets Iowa - Continuous Casting Aluminum Circle for Kitchen Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords