HDPE Geocell for Road Construction, Hot Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1, Specification of Geo cell

1) Material : HDPE/PP/PE

2) Thickness :0.8,0.9,1.0,1.1,1.2mm

3) Height : 50,75,100,150,200,250,300mm

4) Certificate : CE/ISO9001,14001

2, Application of Geo cell

A. firm for the railway roadbed

In order to prevent gravel gradation lateral movement is stronger as a whole to prevent the pumping, even if the soft ground can prevent the collapse of the whole or in part, the large volume of traffic in areas such as the Cross Road, bifurcation Road and turn, can significantly increase the use of Number of years.

B. for a solid roadbed

Can generate high power and flexibility of both traditional and rock embankment on the basis compared to the basis of thickness can be reduced more than 50% of the gravity and contact with the pressure and reduce the horizontal dispersion and can be used when the account or on a permanent road construction .

C. used to bear the gravity of the dam wall

Strengthen the definition of gravel to form the structure of the body has to stop cross-cutting pressure, no matter slide and pool formation, can itself be supported by non-structural surface layer and the natural plant, or a vertical ladder-type design.

D. shallow water for river training

Three-direction grid to enhance the strength of avoid fill soil erosion and increase the load, can reduce the cost of construction of the shallow river and allow river traffic with the design and a variety of soil conditions.

E. support for the pipeline and sewer

To use a more solid foundation for the pipeline, the construction is simple, reducing the excavation, do not have to lay many rocks and avoid part landslide in the long run.

F. used to prevent landslides and heavy-duty force by the retaining wall mixed

Do not have to use the template structure can create a solid wall, and backfill side firmly into the price of one, even if the traditional structure of a variety of gravity is not available, fill materials can also significantly reduce the cost of the project.

G. independence for the strong terminals, such as dams room

Can be quickly wall structure independent from the independent wall, and the use of water in the granular to protect dam, or weir wall, if temporary facilities are to be removed also Geocell back at the pier or breakwater and other important coastal Also use a wide range

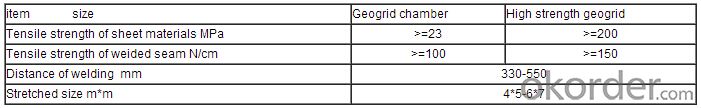

3,Technical data of Geo cell

4.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of construction materials, including but not limited to PP staple fiber, geotextile geo-grid, geo-bag etc. Customized product is also available based on your detailed requirements.

2>How long can we receive the product after purchase?

It takes about 1 to 4 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q: What are the specifications for geotextiles in subsurface drainage projects?

- The specifications for geotextiles in subsurface drainage projects typically include requirements for the material's strength, permeability, filtration properties, and durability. These specifications ensure that the geotextile can effectively separate soil particles from the drainage media, prevent clogging, and maintain its functionality over time. Additionally, the specifications may also address the geotextile's dimensions, weight, and installation guidelines to ensure proper performance in subsurface drainage applications.

- Q: Are geotextiles resistant to abrasion?

- Yes, geotextiles are generally resistant to abrasion. They are designed to withstand rubbing, friction, and wear caused by external forces, making them highly durable and suitable for various applications that involve exposure to abrasive forces.

- Q: How do geotextiles help with soil reinforcement in pavement systems?

- Geotextiles help with soil reinforcement in pavement systems by providing a strong and stable base for the pavement. They act as a separator, preventing the mixing of different soil layers, and also as a stabilizer, distributing the load evenly across the soil. This helps to prevent the settlement and deformation of the pavement, ultimately enhancing its durability and longevity.

- Q: How do geotextiles help in slope stabilization?

- Geotextiles help in slope stabilization by providing reinforcement and erosion control. They are placed on slopes to prevent soil erosion and the movement of soil particles, effectively stabilizing the slope. The geotextiles act as a barrier, allowing water to pass through while retaining the soil in place. This helps to prevent landslides, soil erosion, and slope failure, ensuring the long-term stability and safety of the slope.

- Q: How do geotextiles contribute to groundwater recharge?

- Geotextiles can contribute to groundwater recharge by acting as a filtration system, allowing water to pass through while preventing the movement of soil particles. This helps to prevent the clogging of recharge basins or infiltration trenches, ensuring a more efficient recharge of groundwater.

- Q: What are the factors to consider when selecting a geotextile?

- When selecting a geotextile, there are several factors to consider. These include the specific application or project requirements, the physical and mechanical properties of the geotextile, the site conditions and environmental factors, the expected lifespan and durability of the geotextile, and the cost-effectiveness of the product. It is important to assess these factors to ensure that the chosen geotextile will effectively meet the project needs and provide long-term performance.

- Q: Geotextile detection frequency

- First according to customer requirements grams / square meters, thickness, width, with or without the use of chemical fiber requirements, proofing, and the proofing process parameters, including feed speed, other machines and other parameters of the speed record, Do twenty to ten meters, to test, if qualified, to do so, a lot of bulk, do a few days and then try to seize what the general geotextile manufacturers themselves to prepare several commonly used testing equipment,

- Q: U400 geotextile u400 what it means

- Is not 400g / ㎡ of geotextile? My company specializes in the production of geotextiles, details (hand) to see capital (machine) material

- Q: How do geotextiles help with subgrade stabilization in road construction?

- Geotextiles help with subgrade stabilization in road construction by acting as a barrier between the unstable or weak subgrade soil and the overlying layers of the road. They prevent the mixing of different soil layers, providing separation and reinforcement. Geotextiles distribute the load more evenly, reducing stress on the subgrade and minimizing deformations and settlements. Additionally, they improve drainage by allowing water to pass through while preventing soil erosion, ensuring long-term stability and durability of the road.

- Q: What are the advantages of using geotextiles over traditional construction materials?

- There are several advantages of using geotextiles over traditional construction materials. Firstly, geotextiles are lightweight and flexible, making them easier to handle and install compared to heavy materials like concrete or steel. Secondly, geotextiles have a high strength-to-weight ratio, providing excellent reinforcement and stabilization capabilities for soil and other materials. Additionally, geotextiles are permeable, allowing for proper drainage and preventing water buildup, which can lead to erosion or structural damage. Moreover, geotextiles are resistant to biological degradation, chemicals, and UV radiation, ensuring their long-term durability. Lastly, geotextiles are cost-effective, as they require less labor and equipment for installation and maintenance compared to traditional materials. Overall, the use of geotextiles offers numerous benefits in terms of efficiency, functionality, and sustainability in construction projects.

Send your message to us

HDPE Geocell for Road Construction, Hot Sale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords