Plastic HDPE Geocell for Road Slope Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

HDPE Geocell with CE Certificate (Manufaturer directly!)

Geocell Cellular Confinement Systems / Geocell / Geocell systems / HDPE Smooth/Textured Plastic Geocell

1.welding distance:330-1000mm

2.height:50-250mm

3.Textured or Smooth surface

4.Color: black,brown,green

we are one of the largest geocell factory in China.

Specification:

Polymer Density | High Density Polyethylene with density of 0.935 - 0.965 g/cm3 ASTM D 1505 |

Environmental Stress Crack Resistance | > 4000 hours ASTM D 1693 |

Carbon Black Content | Carbon black content 1.5% - 2.0% ASTM D 1603 |

Sheet Thickness | Smooth:1.1mm,1.2mm,textured:1.5mm ASTM D 5199 |

Cell Details | welding distance:330-1000mm |

Cell Depth | 50-250mm |

Seam Peel Strength | As per US Army Corps of Engineer's Report GL-86-19 Appendix A |

Seam Hang Strength | A 100mm wide seam sample supports a 72.5 kg load for a minimum of 30 days in an ambient room temperature environment. |

Certification | CE ,ISO |

Item Model | Height (mm) | Welding distance (mm) | Sheet thickness (mm)

| Tensile yield strength of the cell (MPa) | Seam peel strength (N/250px) | |

smooth | textured | |||||

TGLG-50-400 | 50 | 400 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

TGLG-100-400 | 100 | 400 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

TGLG-150-400 | 150 | 400 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

TGLG-200-400 | 200 | 400 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

TGLG-75-330 | 75 | 330 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

TGLG-100-330 | 100 | 300 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

TGLG-150-330 | 150 | 330 | 1~1.1 | 1.4~1.5 | 20.0 | 1000 |

Notes:

(1)welding distance:330mm~800mm

(2)we can produce smooth/textured geocell, perforated/non-perforated geocell

(3)The special spec or size can be manufactured according to the demands of the contract

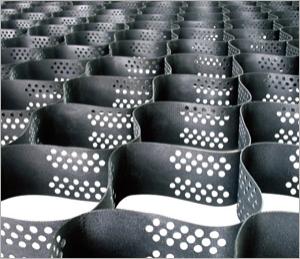

Images of Geocell

- Q: Can geocells be used in load support for heavy machinery yards?

- Yes, geocells can be used effectively in load support for heavy machinery yards. Geocells are strong and durable cellular confinement systems that provide stability and reinforcement to the ground. They are designed to distribute heavy loads and prevent soil erosion, making them ideal for supporting heavy machinery in yards. Geocells offer a cost-effective and environmentally friendly solution for load support, improving the overall efficiency and safety of heavy machinery operations.

- Q: How do geocells improve the performance of green spaces?

- Geocells improve the performance of green spaces by providing structural support, erosion control, and soil stabilization. These three key elements contribute to the overall durability and functionality of green spaces, allowing them to withstand heavy foot traffic, vehicular loads, and adverse weather conditions. Additionally, geocells promote healthy plant growth by enhancing water drainage and nutrient retention in the soil, resulting in more robust and sustainable green spaces.

- Q: Can geocells be used in subgrade stabilization?

- Yes, geocells can be used in subgrade stabilization. Geocells are three-dimensional cellular confinement systems made from high-density polyethylene material. They are commonly used in civil engineering projects to enhance the stability of weak subgrade soils. By confining and reinforcing the soil, geocells distribute loads more efficiently, reducing lateral movement and improving overall stability. This makes them a practical and effective solution for subgrade stabilization.

- Q: Can geocells be used in load transfer platforms for power plants?

- Yes, geocells can be effectively used in load transfer platforms for power plants. Geocells are cellular confinement systems that provide stability and load-bearing capacity to the ground. They can be utilized to create a stable and strong foundation for heavy loads, such as those found in power plants. By distributing the load evenly and preventing lateral movement, geocells can enhance the structural integrity and longevity of load transfer platforms, making them suitable for power plant applications.

- Q: Can geocells be used in avalanche protection measures?

- Yes, geocells can be used in avalanche protection measures. Geocells are three-dimensional honeycomb-like structures made of high-density polyethylene that can be filled with various materials such as soil, gravel, or concrete. These structures can be used to reinforce slopes and provide stability, which is crucial in avalanche-prone areas. By installing geocells, the risk of avalanches can be reduced by improving slope stability and preventing snow buildup. Additionally, geocells can help in redirecting avalanche flow, enhancing the effectiveness of other avalanche protection measures.

- Q: How do geocells improve the stability of embankments?

- Geocells improve the stability of embankments by confining and reinforcing the soil within their honeycomb-like structure. This confinement prevents lateral spreading of the soil particles, enhancing shear resistance and overall stability. Additionally, geocells distribute vertical loads more evenly, reducing settlement and improving the embankment's resilience to external forces like erosion and vibrations.

- Q: Are geocells suitable for pipeline trench reinforcement?

- Yes, geocells are suitable for pipeline trench reinforcement. Geocells are cellular confinement systems made of interconnected HDPE (high-density polyethylene) strips that form a three-dimensional honeycomb-like structure. They can be filled with various materials such as soil, aggregate, or concrete to create a stable and reinforced foundation for pipeline trenches. Geocells provide excellent load distribution, prevent soil erosion, increase load-bearing capacity, and improve overall stability, making them an ideal solution for pipeline trench reinforcement.

- Q: How do geocells improve the stability of foundations?

- Geocells improve the stability of foundations by confining and reinforcing the soil, creating a stronger and more stable base. The honeycomb-like structure of geocells provides lateral support, preventing lateral spreading of soil particles and increasing their shear strength. This confinement also enhances load distribution, reducing settlement and allowing for better load-bearing capacity. Additionally, geocells improve drainage and prevent erosion, further enhancing foundation stability.

- Q: Are geocells suitable for use in ground reinforcement for solar farms?

- Yes, geocells are suitable for use in ground reinforcement for solar farms. Geocells provide excellent stabilization, erosion control, and load distribution capabilities, making them ideal for supporting the heavy equipment and panels in solar farms. Furthermore, geocells offer long-term durability, easy installation, and cost-effectiveness, making them a reliable choice for ground reinforcement in solar farm projects.

- Q: Are geocells suitable for temporary applications?

- Yes, geocells are suitable for temporary applications. Geocells are flexible cellular structures made from high-density polyethylene (HDPE) that can be easily deployed and removed. They are commonly used for temporary applications such as site access roads, construction platforms, and erosion control measures. Geocells provide stability and reinforcement to the underlying soil, allowing for safe and temporary usage in various construction and infrastructure projects.

Send your message to us

Plastic HDPE Geocell for Road Slope Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords