HDPE Geocells for Driveways in Road and Slope Surface Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of HDPE Geocell in Road and Slope Surface Protection

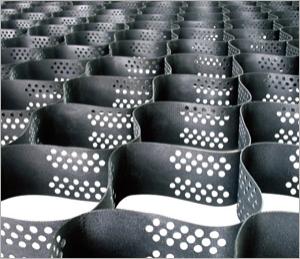

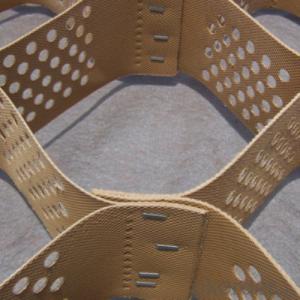

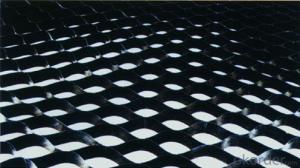

Geocell is a new type of high-strength geosynthetics, which is popular in domestic and abroad. It is a kind of three-dimensional network structure shaped by high-strength HDPE sheets through ultrasonic welding of high strength. Currently, it is being widely used in construction, such as highway, railway, bridge, dyke, etc.

Main Features of Geocell in Road and Slope Surface Protection

1.Light weight, wear-resistant, chemical stability, light oxidation aging, anti-acid/alkali corrosion, applied to different geological conditions, such as saline soil, desert, etc.

2.Wide temperature range, high tensile strength, good rigidity and toughness, good load capacity and anti-erosion ability.

3.Size is relatively stable, change the height and welding distance can meet the needs of different projects.

3.Retractile, easy to transport.

4.Easy to use, can use the local materials and achieve rapid construction, reduce construction costs.

5.Can be used repeatedly.

Specifications of Geocell in Road and Slope Surface Protection

Product Type | Height(mm) | Welding Distance(mm) | Thickness (mm) | Tensile Strength of Welding Points(N/cm) | Tensile Strength of Connection of Cells(N/cm) | Tensile Strength at Yield of Each Sheet(N/Mpa) |

Flat and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.1/1.2 | ≥100 | ≥120 | ≥20 |

Flat and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.1/1.2 | ≥100 | ≥120 | ≥20 |

Embossed and Not Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5 | ≥100 | ≥120 | ≥20 |

Embossed and Perforated | 50≤H≤250 | 330≤A≤1000 | 1.5 | ≥100 | ≥120 | ≥20 |

Remarks: Width of the product can be made according to the customer’s demand, and the other special standards will be carried out by agreement or contact. (The product has past CE certification) | ||||||

Applications of Geocell in Road and Slope Surface Protection

1.To stable the roadbed of highway/railway.

2.To bear the load of dyke, retaining wall.

3.To improve the watercourse of shallow river.

4.To support the pipeline and sewer.

5.To be used as independent wall, wharf and breakwater, etc..

6.To be used for the regulation of the desert, beaches, river bed and river bank.

Methods

In construction, the geocell can be pulled into a network and launched into a three-dimensional honeycomb grid, then filled with soil, macadam, concrete or other granular materials to constitute to be a structure with strong lateral restriction and large stiffness.

Concrete construction method

1.Open the superimposed geocell.

2.Fixed with nails or connected with the framework of stretching device.

3.Fill the particle filler until the full and beyond standard room to the top, then vibrate or roll to finish the primary work.

4.At this point, cell chamber system can support all kinds of construction equipment. The construction can be done directly in the above.

IMages of Geocell in Road and Slope Surface Protection

RFQ:

Q1:Can you provide a sample for us?

A:yes,we can provide for your free samples based on freight collect.

Q2:What is your MOQ?

A:MOQ is 10000sqm.

Q3:What is payment terms?

A:T/T,L/C

Q4:What is your lead time?

A:According to your order quantity,usually 7days for 1*40HC

Q5:Do the customized design accepted?

A:We welcome customized design.

- Q: Can geocells be used in underground drainage systems?

- Yes, geocells can be used in underground drainage systems. Geocells provide structural support and reinforcement to the soil, preventing soil erosion and maintaining the integrity of the underground drainage system. Additionally, geocells can enhance water flow and filtration through their open-cell structure, making them suitable for use in underground drainage systems.

- Q: Do geocells require specialized equipment for installation?

- Yes, geocells typically require specialized equipment for installation. This includes heavy machinery such as compactors, loaders, and graders to prepare the site and ensure proper compaction of the cells. Additionally, special installation tools such as tensioning devices and connectors may be needed to secure the geocells together.

- Q: Are geocells resistant to freeze-thaw cycles?

- Yes, geocells are resistant to freeze-thaw cycles. The cellular structure of geocells allows for expansion and contraction during freezing and thawing, preventing damage and maintaining their structural integrity over time.

- Q: How do geocells enhance surface water management?

- Geocells enhance surface water management by providing a stable and permeable surface that allows for effective water infiltration and management. The interconnected cells create a structure that prevents erosion and helps to retain water, reducing runoff and improving the overall drainage system. This helps to control and mitigate flooding, minimize soil erosion, and protect the environment by promoting sustainable water management practices.

- Q: Can geocells be used for temporary helipads in remote areas?

- Yes, geocells can be used for temporary helipads in remote areas. Geocells are modular, lightweight, and easy to transport and install. They provide a stable and level surface, allowing helicopters to land and take off safely. Moreover, their flexible and permeable design allows for effective drainage and reduces erosion, making them suitable for various terrain conditions in remote areas.

- Q: What are the different materials used in geocells?

- Geocells are typically made from a variety of materials such as high-density polyethylene (HDPE), polypropylene (PP), or polyester. These materials are chosen for their durability, strength, and resistance to environmental factors like UV radiation and chemical exposure.

- Q: Can geocells be used in soil reinforcement for embankments?

- Yes, geocells can be used in soil reinforcement for embankments. Geocells are a type of geosynthetic material that consists of interconnected cells filled with soil or other granular materials. When placed in embankments, geocells provide confinement to the soil, increasing its strength and stability. This reinforcement helps to prevent erosion, slope failure, and settling of the embankment. Geocells are commonly used in various civil engineering applications, including soil reinforcement for embankments.

- Q: How do geocells improve load transfer?

- Geocells improve load transfer by confining and stabilizing the fill material within their honeycomb-like structure. This confinement increases the effective stress distribution, prevents lateral spreading of the fill, and enhances overall load-bearing capacity. Additionally, the interlocking cells create a strong connection between adjacent cells, allowing for efficient load transfer across the entire geocell system.

- Q: How do geocells enhance the stability of cut slopes?

- Geocells enhance the stability of cut slopes by providing a reinforced and stabilized structure. The cellular confinement system of geocells helps to confine the infill material within the cells, preventing it from sliding or eroding. This confinement increases the shear strength of the fill material, reducing the potential for slope failure. Additionally, the interconnected cells distribute the load evenly, improving the overall stability and load-bearing capacity of the slope.

- Q: How do geocells reduce the need for geogrid reinforcement?

- Geocells reduce the need for geogrid reinforcement by providing a three-dimensional structure that confines and stabilizes granular materials, such as soil or aggregate. This confinement enhances the load-bearing capacity of the material, reducing the lateral spreading and vertical settlement. As a result, geocells limit the movement and deformation of the granular fill, minimizing the stress on the underlying geogrid reinforcement and reducing the overall need for it.

Send your message to us

HDPE Geocells for Driveways in Road and Slope Surface Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords