HD Metal Board, HD Aluminium Board, Sublimation Panel Aluminium Sheet, Sublimation Blanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

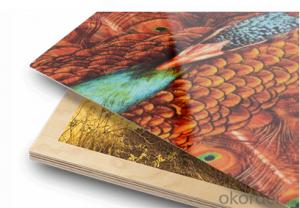

Sublimation Coated Aluminium Sheet

Sublimation aluminium sheet is manufactured specifically for sublimation printing

The hard surface coating on this aluminium is designed for improving image retention

Suggested heat transfer parameter: 200 ℃ and 40 seconds

Safe packaging and film for protection

High quality coating for sublimation and high definition

You can print any logo or pictures on it

Name of the product: Sublimation Coated Aluminium Sheet

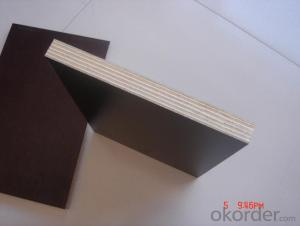

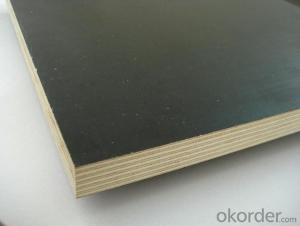

Thickness: 0.45mm,0.55mm, other sizes as your customized

Size: 610*305mm,300*600mm,400*600mm,600*1200mm

Surface finish: Glossy, Matte, Satin, Pure,Pearlized,Brushed,Satin etc

Color: White,Silver,Gold,Cooper,Champange

Protection Film: PE,PVDF,PEVE,UV

Packaging: Seaworthy wooden pallet, wooden case or upon your request

Packaging & Delivery Packaging Details

Seaworthy wooden pallet, wooden case or upon your request

Delivery Detail

15~30 days after deposite

Weight of Packaging

1000 pics per pallet,Around 800 kg

What is WunderBoard HD metal prints?

Wunderboard is high-definition sublimation aluminum:

- Material: Aluminum

- Thickness: 1.14mm (0.045”)

- Biggest size: 1.2x1.2m (different/custom sizes are available)

- Finish: Glossy white

- Coating: 4 layers

--Water-proof, scratch-resistant and anti-UV.

Our advantage such as:

-Similar quality as as the top brand in USA(CHROMALUXE)

-Competitive price (much lower than others competitors)

-Cash Rebate policy and complete supports for distributors

These Aluminum Panels can provide for many sizes and different color. It can suitable in many occasion, like company logo screen, show backdrop, home use, some gift use etc. We can also provide the heat press machine for transferring

The free samples are available, we're pleased to offer you some for testing.

- Q: What is the printing plate roll made of? What are the materials?

- There are several manufacturers in this field in china. Distribution in Chengdu, Yunnan, Shanghai, Shenzhen and other places, layman recommended that you visit the site. The quality of the machine is better than the three.

- Q: Printing and make-up are the same

- Of course, not the same, which is similar to the layout design, to provide customers with text and pictures in accordance with the requirements of CorelDRAW software into vector customer requirements of the customer and board results, is the customer good layout content according to the size of a spell on the page.

- Q: How to repair the printed circuit? How can the printed circuit board be broken by 1cm?

- Printed circuit board, also known as printed circuit board, printed circuit board, is an electronic component of the electrical components connected. The printed circuit board, in accordance with the plate making method in the printing industry, first draws an electronic circuit diagram, and forms a conducting circuit on the insulating board.

- Q: The difference between the 60 and 100 lines of the printing roller

- The principle of letterpress printing is relatively simple. In gravure printing, printing machine inking device to make the ink distribution, then the ink transferred to the printing plate through the roller, due to the graphic part relief is much higher than that of the graphic part, on the plate and therefore, only the ink roller transferred to the printing elements, rather than the graphic part no ink.

- Q: How can I place the printing rollers in the most convenient place?

- With two vertical hook welding iron roller in the warehouse at the corner of wall can be guaranteed and two pending such local quality of roller.

- Q: What's the color of the print edition?

- In the subtractive primaries color (yellow, magenta, cyan and black printing). If you use yellow, magenta, cyan, black ink, four colored ink other than the color ink to copy the original color printing process, should not be called "four color printing", but should be called "spot color printing" or "point color printing."".With red, yellow, blue and black pigment (or dye ink) by lithographic printing method of full color copy of the subtractive color mixing principle.

- Q: Can I make a screen print?

- It can be done, but you have to buy the following materials:1..2. nets frame3. photosensitive adhesive4. you want to make a film version of the film5. light source for printing

- Q: How to prevent white leakage before printing?

- Trap first start from the computer, the most simple method in color when setting a border line, and choose to overprint border line (Overprint). Have a walk this line even when printing, will show the white line, there will only be a dark line. Trap work may seem simple, but if the color layout of multiple and complex, there will be mistakes in the. In the requirements of the guests, trapping white color is also a sophisticated problem, if blue with yellow plus line, line is green, this effect will affect the layout design, to achieve the trap and do not appear green line, resulting in a lot of trap skills.

- Q: What does the PS version of the print mean?

- The light splitting type is used to print the original image of the positive image. The diazo compound in the non image part is broken down by the photolysis and dissolved by the developing solution. The diazo compound that remains on the plate is still not visible. PS version of the pro oil part is a high publication base plane about 3 m diazo photosensitive resin, is a good lipophilic hydrophobic film, ink is easy to spread on top, and water is difficult to spread on it. Diazo photosensitive resin also has good wear resistance and acid resistance. If the baking temperature of 230 ~ 240 DEG C for 5 ~ 8min, and the photosensitive film of enamel, but also can improve the hardness of the plates, plates rate up to 20 ~ 300 thousand. PS version of the hydrophilic part is three oxidation two aluminum film, high publishing base plane about 0.2 ~ 1 m, hydrophilic, wear resistance, chemical stability is better, so the printing plate printing rate is relatively high. PS version of the fine grain, high resolution, the formation of network clean and complete, so the color reproducibility, high image sharpness; a blank part of the PS version of the high moisture capacity, printing plate of large water consumption, water, Mo Pingheng easy to control.

- Q: Why is the screen printing broken?

- There are two kinds of broken screen:1, silk broken2, the film version brokenYou said the screen broken, probably refers to the latter, that is, broken version of film.

Send your message to us

HD Metal Board, HD Aluminium Board, Sublimation Panel Aluminium Sheet, Sublimation Blanks

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords