H20 Timber Beam Formwork with Single Side Bracket for Retaining Wall

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

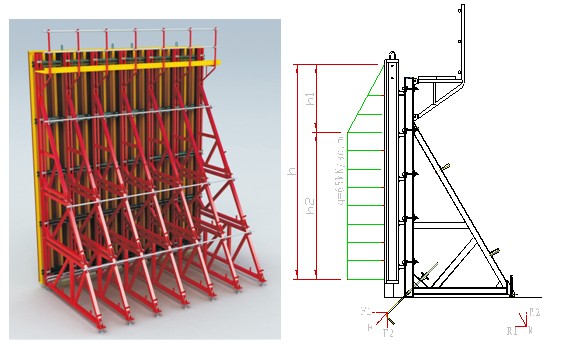

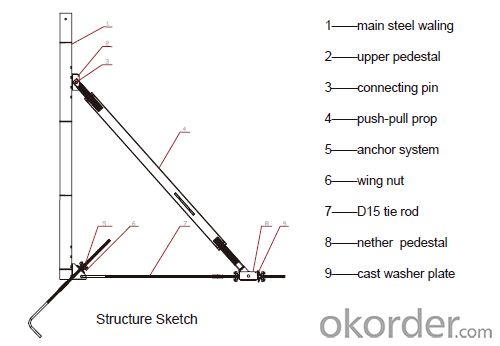

1. Structure of H20 Timber Beam Formwork with Single Side Bracket

During single-sided concrete wall construction, the concrete pressure is transferred into the sub-structure by means of the single-side bracket.

There is no wall-through tie-rod in the single-side bracket system. The whole system is adjusted by the anchor system and the regulator system.

The stress situation from the sketch above.F1 can resist the side pressure of the concrete and F2 can resist the rising force. R can not only bear the gravity force of the bracket, but also the side pressure of the concrete. This stress system is simple, reasonable and also with convenience and high safety.

2. Main Features of H20 Timber Beam Formwork with Single Side Bracket

1. The pouring height is up to 8.0m and the allowable pressure from fresh concrete is up to a maximum of 60KN/m2.

2. Good standard performance and versatility.

3. Fast element coupling, all units can be quickly connected.

4. The finished wall is excellent and absolutely waterproof.

5. Optimized sizes for transportation.

3. H20 Timber Beam Formwork with Single Side Bracket Images

4. H20 Timber Beam Formwork with Single Side Bracket Specification

5. FAQ of H20 Timber Beam Formwork with Single Side Bracket

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

We can provide you the professional design team.

We can provide fashionable and newest styles for you.

We can design the artwork for you.

Please feel free to customize.

2) What promises can be done by us?

If interested in H20 Timber Beam Formwork with Single Side Bracket, please feel free to write us for any QUOTE.

If printing required, please advise asap because the whole set need much more time to complete.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

Response will be carried out in 24hours after receiving any complain or request.

If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

Packing: As Customer's Requirements

Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

Shipping time:Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days. Other mass qty of H20 Timber Beam Formwork with Single Side Bracket, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: Template support product features

- Provincial workers, the province of material, time, more security. Do not use wood, energy saving, product reusable, so that greatly reduce the construction costs. Improve efficiency: the construction without any technology, a dry will, the efficiency increased by 600% (4 groups of 8 hours can be installed 400 square meters). High degree of safety: complete steel structure, standard parts fastening, tight structure, compact connection, more secure and reliable.

- Q: Template support did not stand good, how to remedy the lower floor?

- First measured how much sink ah, the plate elevation measured first, and then find the design, such a thing is not you can decide, the design may be looking for experts, if the lower 10 to cm it does not matter. But also the size of the kanban, if you say 4 * 4 little problem.

- Q: Does the template support of the beamboard contain the full red scaffolding under the beam?

- According to the above said, the scaffolding of the ultra-high fee refers to the building as a whole more than 25 (remember not clear), so that the height of the frame exceeds the quota, so to calculate, and the template support of the ultra- High height (as if more than 4m), for example, a building forty meters high, but the height of only three meters, it only calculated scaffolding ultra-high, and not calculate the template high, if a single high ten meters Of the plant and the like, it only calculates the template is high and does not calculate the scaffolding ultra high;

- Q: The problems of improper matching of template supporting system and preventive measures

- Prevention and control measures. (1) template support system according to the different types of structures and types of templates to match, in order to coordinate with each other. When used, the necessary verification and review of the support system shall be carried out. In particular, the spacing of the pillars shall be determined to ensure that the template support system has sufficient carrying capacity, stiffness and stability. (2) wood support system, such as with the wood template, the wood support must be nailed tight wedge, the pillars must be strengthened between the pull knot tight, wooden pillars at the foot of the wooden wedge to adjust the elevation and fixed, load up to the wooden template support The system can be used to operate the pillow pile tower, for the nail nail fixed. (3) steel support system The steel leng and support the layout of the form should meet the template design requirements, and to ensure the safety of the construction load, steel pipe support system generally should be buckled as a whole bay, the vertical and horizontal spacing of the column is generally about 1m Load should be used when the dense form), while the addition of bracing and scissors support.

- Q: Bridge template support bowl button steel pipe scaffolding, need to set sweeping pole?

- Bridge template support bowl button steel pipe scaffolding, need to set sweeping pole. Suzhou Zhicheng Construction Scaffolding Engineering Co., Ltd. is engaged in various: door scaffolding, trapezoidal scaffolding, all kinds of casters, steel pipe fastener channel leasing, construction site scaffolding erection, stage structures, interior and exterior decoration scaffolding

- Q: Building template support system force calculation? Is to calculate the support system can withstand the upper pressure!

- Looking for the building structure book to see, the formula so much and how to give you online to play? That bad sign you know that simple, you can calculate the steel frame structure on it

- Q: Unilateral support basement wall waterproof protective layer do not do it? Will there be a broken ring on the waterproofing membrane? Is it possible to destroy the process?

- Exterior wall waterproofing is a branch waterproofing project that ensures that the structure of a building (structure) is not affected by water and that the internal space is not covered by water. Exterior wall waterproofing works in the entire construction project occupies an important position. Exterior wall waterproofing works related to the building (structure) of the basement walls, housing facades and many other external wall structure, its function is to make the building or structure in the design of durable years, to prevent rain, water leakage and groundwater Of the erosion, to ensure that the building structure, the internal space is not subject to defacement, to provide people with a comfortable and safe living environment.

- Q: How long does the width of the template support more than how much height the beam can not be poured at the same time?

- Height of more than 8m or span of more than 18m, the total load of more than 10kN / m2 or centralized line load greater than 15kN / m template support system and the use of beam plate at the same time pouring concrete construction method to immediately stop construction.

- Q: What is a template for pulling bolts

- To the stencil fixed, a two-headed round bar, insert the template, the two tied to the nut

- Q: In addition, for example, in the 30-meter-high pier body pouring continuous beam 0 # block, beam 0 # block can be used to support the bracket (usually block 0 block will be surrounded by the entire pier), but 30 meters high Of the scaffolding if not connected with the bracket, then what is the way to make the stability of scaffolding requirements? Is it only anchoring? Please master answer.

- Scaffolding is the final protection of workers safety, protection of scaffolding stability generally use sliding mode

Send your message to us

H20 Timber Beam Formwork with Single Side Bracket for Retaining Wall

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords