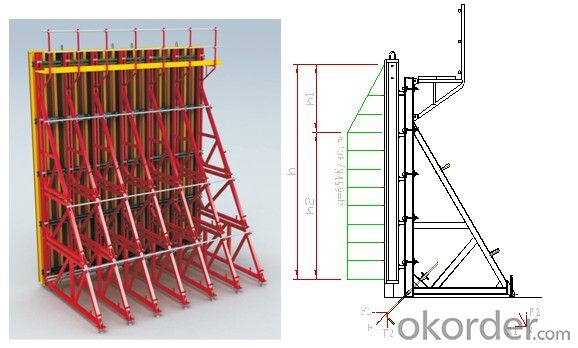

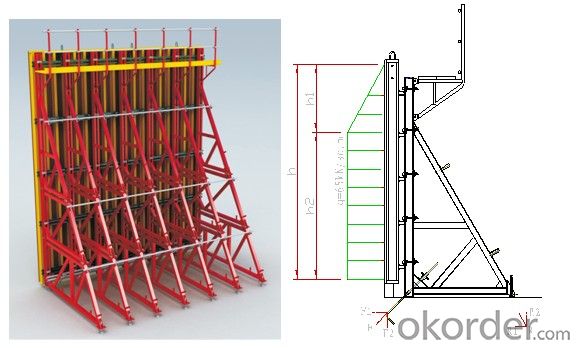

H20 Timber beam formwork with single side bracket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

concrete wall formwork

retaining wall formwork

permanent formwork systems

During single-sided concrete wall construction, the concrete pressure is transferred into the sub-structure by means of the single-side bracket.

Design Principle:

There is no wall-through tie-rod in the single-side bracket system. The whole system is adjusted by the anchor system and the regulator system.

The stress situation from the sketch above.F1 can resist the side pressure of the concrete and F2 can resist the rising force. R can not only bear the gravity force of the bracket, but also the side pressure of the concrete. This stress system is simple, reasonable and also with convenience and high safety.

Competitive Advantage:

1. The pouring height is up to 8.0m and the allowable pressure from fresh concrete is up to a maximum of 60KN/m2.

2. Good standard performance and versatility.

3. Fast element coupling, all units can be quickly connected.

4. The finished wall is excellent and absolutely waterproof.

5. Optimized sizes for transportation.

Applications:

- Q: How to prevent the template support collapsed

- Second, pay close attention to promulgated the "construction template engineering safety technical specifications." In the design calculation, it is necessary to determine the load combination according to the most unfavorable principle in order to solve the problem of the foundation deformation and the overall stability in order to ensure that the template support is the geometric invariant system ; In the quality of steel pipe fasteners to be strictly controlled, and develop practical quality inspection and acceptance methods. The following are the same as the "

- Q: How does the new building shear wall template support safe operation?

- Tian Jian Building Materials Co., Ltd. Shear wall template support known as the construction of the construction area of small assistants, it can be flexible to adjust the length and height, to adapt to any circumstances of the construction, to help the construction of construction companies to solve one after another construction problem

- Q: The template supports how security issues are under the supervision notice

- There are many types of supervision, need that kind. The specific circumstances of the specific office. And then the written supervision notice rectification.

- Q: Roof plate support combination structure

- Xingmin Weiye roof plate template support structure is one of my company's patented product, the roof template support combination structure by the main keel, vice keel, supporting the top of the bar, the tie rod together, the four together form a roof template support system.

- Q: Does the template support of the beamboard contain the full red scaffolding under the beam?

- Many times it is easy to mix the template support with the scaffolding, the template support is to play a supporting role, scaffolding is the platform for workers to operate, both because of the same material so easy to be confused.

- Q: More than a certain size of the larger risk of the template works and support system which include

- Always looking at someone else to go to bargain-hunting that is difficult, others are very HIGH when you do not HIGH, the results of the market start, you unconsciously. Baidu search

- Q: How to use template support?

- This picture is marked on the non-adjustable support, and now generally use adjustable height support.

- Q: The use of new type of shear wall template support structure cost and rental cost

- The current market demand for the wall gradually increased, taking into account the loss rate of timber and construction enterprises to buy wood need to increase the pressure on the use of funds, the use of timber construction prone to mold, up mold, concrete forming poor impact wall flatness, according to market construction Enterprise traditional construction cost cost comparison calculation, the market preferential rental price of 0.5 yuan per day -0.6 yuan per square meter.

- Q: A load that can be sustained by a fastener

- According to the amount of concrete set quota of stall sales, and then according to the scale of the project, the number of layers, the form of the form and the number of turns to determine the template.

- Q: Frame support system in the framework of the support system of wood support has been unable to withstand the pressure, the use of steel frame as a wooden mold support system, with steel pipe as a support system used in the bolt fasteners, etc., how much money Ton. How much is a fastener, the above is not used in the construction industry used in the external scaffolding, stressed! The Is the kind of support system as a wood template! Please give the professionals a detailed answer! There is the price, that place to sell? The

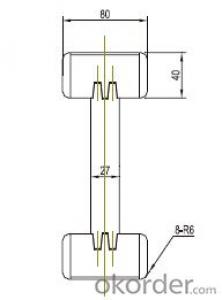

- Pad wood template should be called I-shaped steel bar, there are several other names of steel "H-beam, T-beam, I-shaped steel, channel, angle" like these large steel market are sold

Send your message to us

H20 Timber beam formwork with single side bracket

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches