Premium Table Formwork System

- Loading Port:

- XINGANG

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 500 Square Meter/Square Meters cm²

- Supply Capability:

- 12000 Square Meter/Square Meters per Month cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction of Premium Table Formwork System

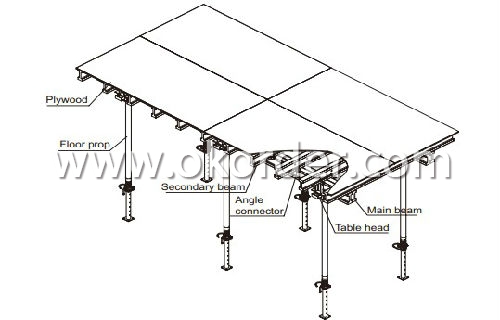

Table formwork system

Table formwork is widely used in the high and super high building, Flat slabs of concrete

structure construction of multi-storey industrial plant, etc. can be matched with the slab

form in bulk.Lifting by lifting fork, moving by shifting trolley make it especially cost-effective

and save the labor cost.

Table Formwork System can be devided into Ring-Lock Table Formwork as below and

Prop Table Formwork following.

High-grade raw materials;

High quality, low price;

Dimensional stability.

Can be used for slab

Table Formwork System

2.Characteristics of Table Formwork System

Table formwork is the most typical application for slab,with timber beam,the slab formwork

is light weight,fast and economic in the construction.

T Table Formwork

The standard size is 2440mm×4880mm and 3300mm×5000mm

Seeing the follow Sketch:

Table formwork accessories details

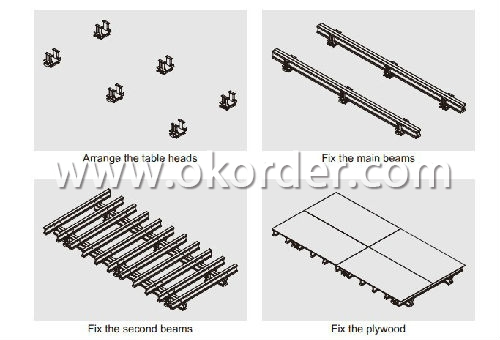

Component with high standardization

Assembling in site,flexible application

Light weight,easy transportation and storage

Assemble instructions

3.Project Application of Table Formwork System

Our company can offer you a general proposal based on your structural drawings.

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Regular inspection of the climbing device should check the connections. In particular, the following parts of the site to focus on inspection and reinforcement: according to the design requirements of the bolt with spring washers

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame installation processInstallation of platform --- display base, installation guide, assembling components - horizontal truss beam with the bolt on the guide rail, the main frame vertical rod buckle on the beam - diagonal rod buckle on the vertical rod and beam - wall installation guide device, the frame structure of unloading with elevated body, the erection of scaffolding, the laying of the intermediate layer or temporary scaffolding and temporary building structure frame of pulling and hanging outside the dense mesh safety net - loaded third beams to guide seat -

- Q: The difference between the scaffold and the scaffold

- The climbing frame is the kind of iron that is assembled by a large construction site

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- 3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- The climbing frame, which is also called the lifting frame, can be divided into several types, such as hydraulic, electric, manual and so on. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction.

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 1949 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | SHANGHAI |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 200 |

| Language Spoken: | English,Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Premium Table Formwork System

- Loading Port:

- XINGANG

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 500 Square Meter/Square Meters cm²

- Supply Capability:

- 12000 Square Meter/Square Meters per Month cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords