High Yield Steel Deformed Bar of Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High Yield Steel Deformed Bar of Building Material

Description of High Yield Steel Deformed Bar

1, Diameter: 5.5mm-10mm High Yield Steel Deformed Bar

10m- 40mm High Yield Steel Deformed Bar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of High Yield Steel Deformed Bar

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

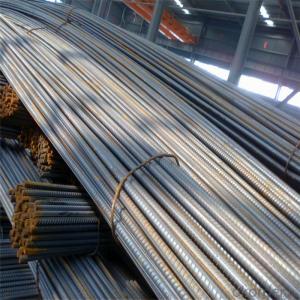

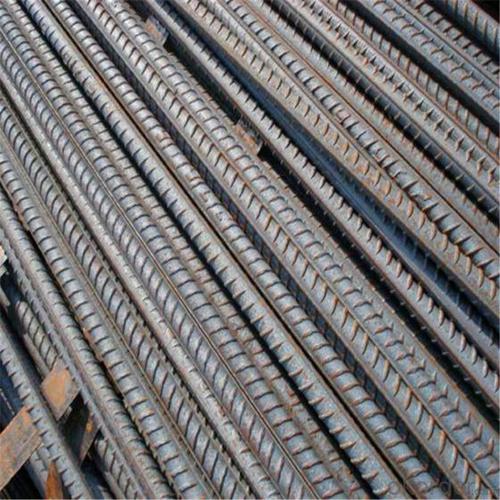

Products Show of High Yield Steel Deformed Bar

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different processes involved in making special steel?

- The different processes involved in making special steel include melting and refining the raw materials, such as iron ore and scrap metal, in a furnace to create liquid steel. This liquid steel is then cast into various shapes using techniques like continuous casting or ingot casting. After casting, the steel undergoes heat treatment processes like annealing, quenching, and tempering to enhance its mechanical properties. Additionally, special alloying elements are added during the melting stage to give the steel specific characteristics, such as increased strength or corrosion resistance. Finally, the steel is finished by processes like machining, grinding, and polishing to meet the desired specifications and quality standards.

- Q: How does special steel contribute to reducing product costs while maintaining quality?

- Special steel contributes to reducing product costs while maintaining quality through several ways. Firstly, special steel possesses enhanced strength and durability, allowing manufacturers to produce products with thinner gauges or smaller dimensions, reducing material usage and overall costs. Additionally, its superior corrosion resistance and longevity ensure that the products have a longer lifespan, reducing the need for frequent replacements. Moreover, special steel's exceptional machinability enables efficient production processes, reducing labor costs and increasing productivity. Lastly, its high precision and consistency in manufacturing contribute to minimizing defects and waste, resulting in cost savings and improved product quality. Overall, special steel's unique properties and characteristics enable manufacturers to optimize production, thereby reducing costs without compromising on product quality.

- Q: How is special steel used in the manufacturing of machinery?

- Special steel, with its unique properties that make it highly suitable for the manufacturing of machinery, is an essential component in this process. It refers to a category of steel alloys that have been specifically designed and developed to possess exceptional strength, durability, and resistance to wear and tear. In various applications within the manufacturing of machinery, special steel is commonly used. One primary use is in producing machine components requiring high strength and toughness, such as gears, shafts, bearings, and fasteners. These components endure heavy loads, high temperatures, and harsh operating conditions, necessitating the ability to withstand these stresses without failure or deformation. Special steel provides the required strength and toughness for ensuring the longevity and reliability of these machine parts. Furthermore, special steel is utilized in manufacturing cutting tools and dies. Cutting tools, including drills, milling cutters, and lathe tools, require excellent hardness and wear resistance to endure the forces and abrasion encountered throughout the machining process. Dies, on the other hand, are used for shaping or forming materials and necessitate high strength and hardness to endure repetitive pressure and deformation. Special steel offers the necessary properties to enhance the performance and lifespan of these cutting tools and dies. Moreover, special steel frequently finds application in constructing machine frames and structural components. Its strength and rigidity make it ideal for supporting heavy loads and maintaining overall machinery stability. By incorporating special steel into machine frame construction, manufacturers can ensure the structural integrity and durability of the machinery, which is crucial for safe and efficient operation. In conclusion, special steel plays a vital role in the manufacturing of machinery by providing the necessary strength, durability, and wear resistance for critical machine components, cutting tools, and structural elements. Its unique properties make it indispensable in producing high-performance machinery capable of enduring the demanding conditions of various industries.

- Q: What are the different forming techniques for special steel?

- Some of the different forming techniques for special steel include forging, rolling, extrusion, and casting.

- Q: How does maraging steel achieve high strength through aging?

- Maraging steel achieves high strength through aging by undergoing a process called precipitation hardening. This involves heating the steel to a specific temperature and holding it there for a certain period of time, followed by rapid cooling. This process allows the formation of fine, intermetallic particles within the steel's microstructure, which greatly enhances its strength. Additionally, the aging process helps relieve residual stresses and improves the steel's toughness and corrosion resistance.

- Q: What are the different corrosion testing methods used for special steel?

- There are several corrosion testing methods utilized for special steel to assess and evaluate its resistance against corrosion. Some of the commonly used techniques include: 1. Salt Spray Testing: This method involves subjecting the special steel to a controlled saltwater mist environment. The steel specimen is placed in a salt spray chamber, and the exposure duration can vary depending on the specific requirements. The resulting corrosion can be visually evaluated and compared against standard criteria. 2. Electrochemical Testing: Electrochemical techniques such as potentiodynamic polarization and electrochemical impedance spectroscopy (EIS) are widely used to study the corrosion behavior of special steel. These methods involve measuring the current and potential responses of the steel in various corrosive solutions to determine the corrosion rate and other electrochemical parameters. 3. Immersion Testing: In this method, the special steel is immersed in a specific corrosive solution for a predetermined period. The solution can be acidic, alkaline, or even simulated seawater depending on the intended application. The weight loss or surface damage caused by corrosion is then measured and compared to evaluate the steel's corrosion resistance. 4. Crevice Corrosion Testing: This technique focuses on evaluating the susceptibility of special steel to crevice corrosion, which occurs in confined spaces or gaps. A crevice is created between the steel specimen and another material, and a corrosive solution is introduced into the crevice. The severity of crevice corrosion is assessed by measuring the depth of attack or using electrochemical methods. 5. Intergranular Corrosion Testing: Special steel can be prone to intergranular corrosion, which occurs along the grain boundaries. Tests like the Strauss test or the Huey test are conducted to determine the steel's susceptibility to this form of corrosion. These tests involve immersing the steel in a corrosive solution at elevated temperatures and assessing the extent of intergranular attack. 6. Accelerated Testing: Accelerated corrosion testing methods aim to simulate long-term corrosion effects within a shorter time frame. Techniques like cyclic corrosion testing, which includes alternating exposure to various corrosive environments, can provide valuable insights into the steel's performance under realistic conditions in a shorter time period. It is important to note that the selection of the corrosion testing method depends on the specific requirements, intended application, and environmental factors that the special steel will be exposed to.

- Q: How does special steel contribute to the hardness of products?

- The hardness of products is enhanced by special steel due to its distinct composition and manufacturing techniques. Unlike regular steel, special steel is mixed with additional elements like chromium, nickel, and manganese, which bolster its strength and durability. These alloying elements combine with the steel matrix to form solid solutions, resulting in a more rigid and compact structure. The inclusion of these alloying elements in special steel allows for the creation of diverse microstructures, including fine-grained structures and martensitic structures, which significantly increase the steel's hardness. Moreover, special steel often undergoes heat treatment processes such as quenching and tempering, which further refine its microstructure and enhance its hardness. Furthermore, the hardness of special steel can also be influenced by the manufacturing processes employed, such as hot rolling or cold working. These processes deform the steel, align its grain structure, and minimize any defects or impurities, resulting in a more uniform and harder material. The hardness of special steel plays a vital role in various industries where strength, wear resistance, and resistance to deformation are crucial. For instance, in the automotive industry, special steel is utilized in the production of engine parts, gears, and axles, all of which require high hardness to withstand challenging conditions and loads. Similarly, in the construction industry, special steel is used for manufacturing tools, cutting blades, and reinforcement bars, where hardness is essential for longevity and performance. In conclusion, special steel's contribution to product hardness is attributed to its unique alloying elements, manufacturing techniques, and heat treatments. Its ability to form various microstructures and its resistance to deformation make it an excellent material for applications where hardness is vital for performance and durability.

- Q: How does special steel contribute to the manufacturing of hydraulic components?

- Special steel plays a crucial role in the manufacturing of hydraulic components due to its unique properties and characteristics. Hydraulic components, such as cylinders, pumps, valves, and fittings, work under high pressure and extreme conditions. Therefore, they require materials that can withstand these demanding environments. Special steel, also known as alloy steel, is specifically designed to possess exceptional strength, durability, and resistance to corrosion and wear. These properties make it an ideal material for hydraulic components, as they need to withstand high pressures, constant movement, and exposure to various fluids. The high strength of special steel allows hydraulic components to handle heavy loads and resist deformation, ensuring their long-term reliability and performance. Additionally, the durability of special steel ensures that hydraulic components can endure the continuous stress and movement without experiencing premature failures. Another significant advantage of special steel is its resistance to corrosion and wear. Hydraulic components often come into contact with different fluids, including water, oil, and chemicals. Special steel's resistance to corrosion protects the components from degradation and extends their lifespan. Furthermore, its resistance to wear minimizes the damage caused by friction, ensuring smooth operation and reducing maintenance requirements. Moreover, special steel can be easily machined and formed into complex shapes, allowing for the production of intricate hydraulic components with precise specifications. This versatility enables manufacturers to create components that are tailored to the specific requirements of different hydraulic systems, ensuring optimal performance and efficiency. In conclusion, special steel contributes significantly to the manufacturing of hydraulic components by providing the necessary strength, durability, corrosion resistance, and wear resistance. Its unique properties enable the production of high-quality and reliable hydraulic components that can withstand demanding environments and ensure the smooth operation of hydraulic systems.

- Q: How does special steel contribute to the manufacturing of precision instruments?

- Special steel plays a crucial role in the manufacturing of precision instruments. Its unique characteristics and properties make it an ideal material choice for these applications. Firstly, special steel offers exceptional strength and durability, allowing precision instruments to withstand extreme conditions, heavy loads, and repetitive use. This ensures the longevity and reliability of these instruments, which is vital in critical industries such as aerospace, automotive, and medical. Moreover, special steel has excellent corrosion resistance, preventing the instruments from deteriorating over time. This is especially important for precision instruments that are exposed to various elements, chemicals, or moisture during their operation or storage. Special steel also provides high thermal stability, enabling precision instruments to maintain their accuracy in different temperature environments. This is vital for instruments that are used in industries where temperature fluctuations can affect their performance, such as laboratories or manufacturing plants. Additionally, special steel can be customized and tailored to meet specific design requirements. It can be easily machined, formed, or welded into intricate shapes and parts, allowing manufacturers to create precision instruments with complex geometries and tight tolerances. This level of precision is crucial for instruments used in fields like metrology, microscopy, or nanotechnology. Furthermore, special steel offers excellent magnetic properties, which can be advantageous for precision instruments that rely on magnetic fields for their operation. This includes instruments like magnetic resonance imaging (MRI) machines, compasses, or magnetometers. In conclusion, special steel contributes significantly to the manufacturing of precision instruments by providing strength, durability, corrosion resistance, thermal stability, customization options, and magnetic properties. These characteristics ensure the performance, accuracy, and longevity of precision instruments, making them indispensable in various industries.

- Q: What are the requirements for special steel used in marine applications?

- In order to ensure durability and performance in harsh marine environments, special steel used in marine applications must satisfy various specific criteria. These criteria encompass the following: 1. Corrosion resistance: To prevent degradation and maintain its structural integrity over time, special steel utilized in marine applications must possess a high resistance to corrosion, as it is exposed to saltwater in marine environments. 2. Strength and toughness: Steel employed in marine applications must exhibit adequate strength and toughness to withstand the dynamic forces and impacts encountered at sea. It must be capable of enduring heavy loads, extreme temperatures, and the impact of waves or collisions. 3. Weldability: Optimal weldability is a requirement for special steel used in marine applications, as it facilitates the construction and repair of marine structures. This characteristic ensures that the steel can be effortlessly joined without compromising its structural integrity. 4. Fatigue resistance: Special steel employed in marine applications must possess exceptional fatigue resistance to withstand the constant cyclic loading associated with wave motions, currents, and operational conditions. Failure to address this requirement can result in fatigue failure. 5. Low-temperature toughness: Due to the involvement of marine applications in cold climates or icy waters, special steel used in these scenarios must maintain its toughness and ductility even at low temperatures. This characteristic is pivotal in preventing brittle fracture and ensuring safety. 6. Fire resistance: High fire resistance is of utmost importance in marine applications. Therefore, special steel utilized in marine structures should possess a high level of fire resistance to prevent structural collapse and restrict the spread of fire. 7. Easy maintenance: Ongoing exposure to harsh environmental conditions necessitates that special steel used in marine applications be easy to maintain and repair. This ensures prolonged performance and minimizes downtime. To fulfill these requirements, special steel for marine applications frequently undergoes alloying with specific elements such as chromium, nickel, and molybdenum. This enhances corrosion resistance, strength, and toughness. Furthermore, advanced manufacturing processes and quality control measures are implemented to guarantee the highest standards of quality and performance in marine applications.

Send your message to us

High Yield Steel Deformed Bar of Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords