Carbon Structural Steel Round Bars ASTM A36

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Structural Steel Round Bars ASTM A36

PRODUCT SPECIFICATION

1, Chemical Composition %

| Grade | C | Si | Mn | S | P | Cr | Cu |

| ASTM A36 | ≤0.25 | ≤0.40 | 0.80-1.20 | ≤0.050 | ≤0.040 | ≥0.30 | ≥0.20 |

2, Diameter: 9mm - 80mm

APPLICATION

1. Manufacturing of mechanical parts

2. Welding structure building

3. Bridge engineering with higher quality requirements

PRODUCT MAIN POINTS

1, Heat Treatment: normalizing, annealing, tempering, quenching

2, Surface Treatment: black, grinding, bright, polish

3, Product Process: hot rolled, cold drawn, forged

FAQ

1, Payment Terms:

30% T/T deposit & 70% T/T before delivery.

Irrevocable L/C at sight

2, Trade Terms:

EXW, FOB, CIF, CNF

3, Delivery Time:

Normally 30-40 days. According to quantity.

4, Manufacture or Trading Company:

CNBM is a state-owned fortune global 500 trading company. We have intergrated supply system.

There are about 20 overseas locations in different countries.

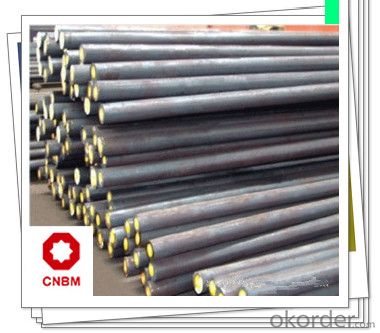

PRODUCT SHOW

ABOUT US

- Q: How do you determine the strength of a steel round bar?

- The strength of a steel round bar can be determined through various methods, including physical testing and material specifications. One common method is to conduct a tensile test, which involves pulling the bar until it reaches its breaking point. This test helps determine the ultimate tensile strength (UTS) of the steel, which is the maximum stress it can withstand before fracturing. The UTS is typically measured in units of force per unit of cross-sectional area, such as pounds per square inch (psi) or megapascals (MPa). Another important strength property to consider is the yield strength. This is the stress level at which the steel starts to deform permanently, without any increase in load. The yield strength is crucial in determining the structural integrity of the bar, as it indicates the maximum load it can bear without undergoing plastic deformation. In addition to physical testing, the strength of a steel round bar can also be determined by its material specifications. Steel manufacturers provide information about the composition and mechanical properties of their products. This includes details about the steel grade, which indicates the alloying elements present in the steel and their concentrations. Different steel grades have varying strength properties, which can help determine the strength of the round bar. It is important to note that the strength of a steel round bar may also be influenced by other factors, such as heat treatment or surface conditions. Heat treatment processes like quenching and tempering can enhance the strength and hardness of the steel, while surface conditions like coatings or treatments can improve corrosion resistance. To accurately determine the strength of a steel round bar, it is recommended to consult the material specifications provided by the manufacturer and consider conducting physical tests, such as tensile testing, if necessary.

- Q: Can steel round bars be used for making universal joints?

- Yes, steel round bars can be used for making universal joints. Steel round bars are commonly used in the manufacturing of universal joints due to their strength, durability, and ability to handle high torque and rotational forces.

- Q: Can steel round bars be used for making fasteners or bolts?

- Yes, steel round bars can be used for making fasteners or bolts. Steel round bars are often used as raw materials for manufacturing fasteners and bolts due to their high strength, durability, and resistance to deformation. They can be shaped, threaded, and heat-treated to meet the specific requirements of fasteners and bolts.

- Q: Can steel round bars be used in the production of fasteners?

- Yes, steel round bars can be used in the production of fasteners. Steel round bars are commonly used as a raw material in the manufacturing of various types of fasteners such as bolts, screws, nuts, and studs. The round shape of steel bars allows for easier machining and forming processes required to create threaded or non-threaded fasteners. Steel is a popular choice for fasteners due to its strength, durability, and resistance to corrosion. Additionally, steel round bars can be easily heat-treated to improve their mechanical properties, making them suitable for a wide range of fastening applications in various industries.

- Q: What is the difference between a rough turned and a centerless ground steel round bar?

- A rough turned steel round bar is a steel bar that has been machined to a standard size and shape using a lathe or turning machine. This involves removing excess material from the bar's surface to achieve the desired diameter and smoothness. The resulting rough turned bar may still have minor imperfections or variations in size and surface finish. On the contrary, a centerless ground steel round bar undergoes a different manufacturing process. This process involves feeding the steel bar through two rotating wheels - a grinding wheel and a regulating wheel. The grinding wheel removes material from the bar's surface to achieve a precise diameter, while the regulating wheel controls the bar's feed rate. This process ensures precise tolerances, an excellent surface finish, and a consistent diameter along the entire length of the bar. In conclusion, the primary distinction between a rough turned and a centerless ground steel round bar lies in the manufacturing process and resulting quality. While a rough turned bar is machined to a standard size and shape with some imperfections, a centerless ground bar undergoes a more precise grinding process to achieve a highly accurate diameter, excellent surface finish, and consistent dimensions throughout the bar.

- Q: What is the maximum titanium content allowed for steel round bars?

- The maximum titanium content allowed for steel round bars typically depends on the specific steel grade and composition. However, as a general guideline, the maximum titanium content in steel round bars is usually around 0.05-0.06%.

- Q: How are steel round bars measured?

- Steel round bars are typically measured by their diameter. The diameter is determined by measuring the distance across the widest point of the bar, usually in millimeters or inches. It is important to note that the diameter measurement is taken at the greatest cross-section of the round bar, which is the distance across the center point. This measurement is crucial for various applications as it helps determine the strength, stability, and load-bearing capacity of the steel round bar.

- Q: What is the tensile strength of a steel round bar?

- The tensile strength of a steel round bar is influenced by a range of factors, including the grade of steel, the manufacturing process, and any additional treatments or coatings applied. Typically, steel round bars exhibit high tensile strength due to their composition and structural design. The specific tensile strength can vary significantly based on the grade of steel. For instance, low carbon steel generally has a tensile strength ranging from 400 to 550 MPa (megapascals), while high carbon steel can have a tensile strength of 700 to 1000 MPa or even higher. It should be noted that heat treatment processes like quenching and tempering can further enhance the tensile strength of a steel round bar, resulting in increased strength and hardness. Additionally, the addition of certain alloying elements such as chromium, nickel, and molybdenum can improve the tensile strength and other mechanical properties of steel. To accurately determine the precise tensile strength of a specific steel round bar, it is essential to refer to the manufacturer's specifications or consult relevant industry standards like ASTM or AISI standards. These standards offer comprehensive information on the mechanical properties, including tensile strength, for different steel grades.

- Q: What is the cost of steel round bars compared to other materials?

- The cost of steel round bars can vary depending on various factors such as the grade of steel, the size and dimensions of the bar, and market conditions. However, in general, steel round bars tend to be more cost-effective compared to other materials commonly used in construction and manufacturing. For instance, when compared to materials like aluminum or titanium, steel round bars are typically more affordable. Steel is abundantly available, making it a cost-efficient choice for many applications. Additionally, steel has excellent strength and durability properties, making it a preferred material for structural purposes. Compared to materials like wood or plastic, steel round bars may be more expensive initially. However, when considering the long-term benefits such as its longevity, resistance to corrosion, and minimal maintenance requirements, steel still offers a cost-effective solution. It is important to note that the cost of steel round bars can vary significantly depending on market conditions, such as the availability of raw materials and the demand for steel products. Additionally, specialized or high-grade steel alloys may come at a higher cost due to their specific properties or manufacturing processes. In summary, steel round bars generally offer a cost-effective option compared to many other materials used in construction and manufacturing. However, it is always recommended to research current market prices and consider specific project requirements before making any final cost assessments.

- Q: What kind of steel pipe is round steel?

- A round bar is not a steel tube. In brief, its section is round, but it is solid, and the cross section of the pipe is hollow.

Send your message to us

Carbon Structural Steel Round Bars ASTM A36

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches