4140 Alloy Steel, 1.7225 Steel Material, SCM440 Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

4140 Alloy Steel, 1.7225 Steel Material, SCM440 Steel Bar

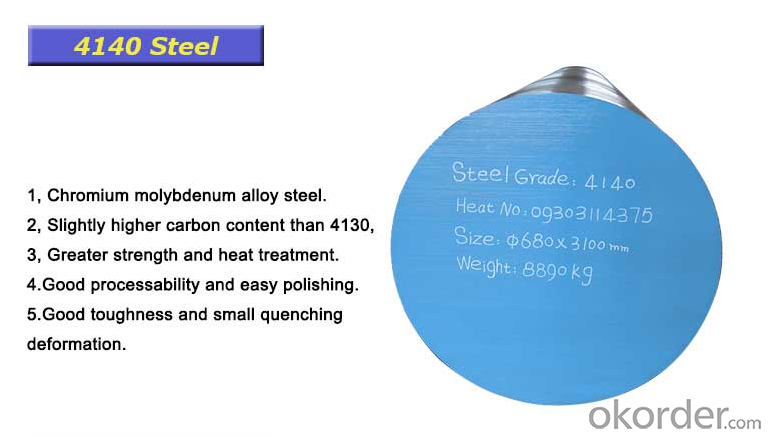

Product information:

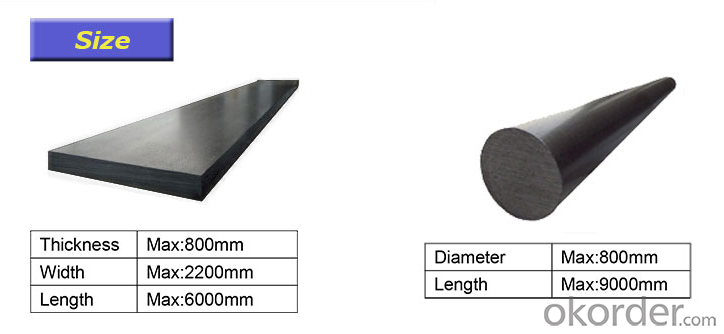

1. Dia:12mm-300mm

2. Standard Performed: ASTM A29/A29M-04

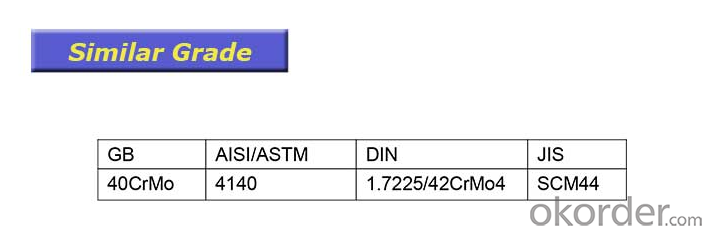

Equal Standard:

America Standard: AISI4140

International Standard: 42CrMo4

Japan Standard: SCM440

Germany Standard: 42CrMo4

4.Grade:ASTM A29 4140 42CrMo SCM440

Hardness:217HB

Tensile strength:1080(110)MPA

Yield strength: 930(95)MPA

elogation:12% Reduction of area:45% AKV(impact value):63J

Product show:

Workshop show:

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: How does special steel resist oxidation at high temperatures?

- Due to the presence of specific alloying elements and a carefully controlled manufacturing process, special steel is able to resist oxidation at high temperatures. When exposed to oxygen in the air, alloying elements like chromium, nickel, and aluminum form a protective oxide layer on the steel's surface. This layer acts as a barrier, preventing further oxidation. Of these alloying elements, chromium is particularly effective in forming a stable and dense chromium oxide layer. This layer serves as a self-healing mechanism, meaning that if it becomes damaged or scratched, it will quickly regenerate and continue to protect the steel from oxidation. The manufacturing process of special steel involves precise control of composition and heat treatment. This ensures that the steel has a fine and uniform microstructure, minimizing the presence of impurities or defects that could speed up oxidation. Moreover, the steel often undergoes various heat treatments, such as annealing or quenching, which further enhance its resistance to oxidation. In conclusion, the combination of alloying elements, controlled composition, and specific manufacturing processes allow special steel to withstand oxidation at high temperatures. This makes it an ideal choice for applications in industries like aerospace, power generation, and petrochemical.

- Q: What is the significance of tensile strength in special steel?

- Tensile strength is of great significance in special steel because it determines the steel's ability to withstand stretching or pulling forces without breaking or deforming. This property is crucial in various industries, especially in manufacturing and construction, where high tensile strength is required for structural integrity and safety. Special steel with superior tensile strength can withstand heavy loads, resist impacts, and provide durability, making it highly sought after in applications such as building infrastructure, automotive manufacturing, and aerospace engineering.

- Q: What are the requirements for special steel used in food processing equipment?

- The requirements for special steel used in food processing equipment include high corrosion resistance to prevent contamination, excellent hygiene and cleanability properties, high strength and durability to withstand heavy usage, and compliance with food safety regulations and standards.

- Q: How does special steel perform in high-stress corrosion cracking environments?

- Special steel is specifically designed to perform well in high-stress corrosion cracking environments. This type of steel is highly resistant to corrosion and can withstand the combination of stress and corrosive elements present in these environments. Its unique composition and manufacturing process make it more durable and less prone to cracking, ensuring its reliable performance in such challenging conditions.

- Q: What is the role of heat treatment in special steel?

- The role of heat treatment in special steel is to enhance its mechanical properties and improve its performance by altering its microstructure through controlled heating and cooling processes. This helps to achieve desired properties such as increased hardness, strength, toughness, and ductility, as well as improved wear resistance and corrosion resistance. Heat treatment also allows for the refinement of grain structure, elimination of internal stresses, and modification of the steel's crystalline structure, which ultimately improves the overall quality and usability of special steel in various applications.

- Q: What is the process of manufacturing special steel?

- The process of manufacturing special steel involves several steps. Firstly, raw materials such as iron ore, coal, and limestone are gathered and processed to create molten iron in a blast furnace. Next, impurities like carbon, sulfur, and phosphorus are removed through various refining techniques. Once the desired composition is achieved, the molten iron is transferred to a steelmaking furnace, where alloying elements like chromium, nickel, or manganese are added to impart specific properties. The mixture is then refined further to remove any remaining impurities and to adjust the temperature and composition. After refining, the molten steel is cast into various shapes such as blooms, billets, or slabs, depending on the desired end product. These primary forms are then subjected to hot rolling, forging, or extrusion processes to shape them into the desired final products, such as bars, plates, or wires. Finally, the manufactured steel undergoes heat treatment processes like annealing, quenching, or tempering to enhance its strength, hardness, and other mechanical properties. It is also subjected to quality control measures to ensure it meets the required specifications. Overall, the process of manufacturing special steel involves a combination of raw material preparation, refining, casting, shaping, heat treating, and quality control steps to produce steel with specific properties tailored to meet diverse industrial needs.

- Q: How is corrosion-resistant stainless tool steel used in the production of food processing equipment?

- Corrosion-resistant stainless tool steel is used in the production of food processing equipment due to its ability to withstand exposure to moisture, chemicals, and high temperatures. This type of steel prevents rusting and corrosion, ensuring the equipment remains hygienic and safe for food processing. It is commonly used for manufacturing blades, cutters, and other components that come into direct contact with food. Additionally, its durability and strength make it ideal for withstanding the rigorous demands of food processing operations, enhancing the equipment's longevity and performance.

- Q: What are the different methods of surface powder coating for special steel?

- There are several methods of surface powder coating that are commonly used for special steel. These methods include: 1. Electrostatic powder coating: This method involves applying an electric charge to the powder particles and then spraying them onto the steel surface. The charged particles are attracted to the grounded steel, resulting in a uniform and durable coating. 2. Fluidized bed powder coating: In this method, the steel is preheated and then dipped into a fluidized bed of powder particles. The heat causes the powder to melt and form a smooth coating on the steel surface. Excess powder is then removed by shaking or blowing air. 3. Flame spray powder coating: This method involves heating the powder particles using a flame and then spraying them onto the steel surface. The heat melts the powder, which then solidifies to form a coating. Flame spray powder coating is often used for larger steel structures or for repairing damaged coatings. 4. Thermal spray powder coating: This method uses a thermal spray gun to heat and propel the powder particles onto the steel surface. The high velocity of the particles ensures good adhesion and a dense coating. Thermal spray powder coating is often used for high-wear applications or in corrosive environments. 5. UV-cured powder coating: This method involves applying a UV-sensitive powder onto the steel surface and then exposing it to UV light. The UV light initiates a chemical reaction that causes the powder to cure and form a hard coating. UV-cured powder coating is known for its fast curing time and excellent resistance to chemicals and UV radiation. Each of these methods has its own advantages and considerations, and the choice of method will depend on factors such as the specific requirements of the steel surface, the desired coating thickness, and the production volume.

- Q: How does special steel contribute to the shipbuilding industry?

- Special steel plays a crucial role in the shipbuilding industry by providing enhanced strength, durability, and corrosion resistance to ships. It allows for the construction of lighter and more fuel-efficient vessels without compromising on structural integrity. Additionally, special steel enables the development of advanced ship components, such as propellers, hulls, and offshore structures, which can withstand harsh marine environments and ensure safer and more reliable operations at sea.

- Q: How does special steel contribute to the aerospace turbine industry?

- The aerospace turbine industry greatly relies on special steel due to its unique advantages that cannot be found in other materials. Special steel is renowned for its exceptional strength and durability, making it perfect for enduring the extreme conditions within aerospace turbines. The demanding temperatures, pressures, and rotational speeds experienced by turbine components necessitate a material that can withstand these harsh conditions without compromising performance or safety. Furthermore, special steel demonstrates excellent heat resistance and corrosion resistance properties, which are vital for the longevity of turbine components. Its ability to resist oxidation and corrosion enables special steel to maintain its structural integrity and functionality over extended periods, reducing the need for frequent maintenance or replacement. Moreover, special steel offers outstanding machinability and formability, enabling the production of intricate and complex turbine components. This facilitates the creation of highly efficient and precisely engineered turbine blades, vanes, and other crucial parts necessary for the optimal performance of aerospace turbines. Additionally, special steel provides the necessary characteristics for enhanced fuel efficiency in aerospace turbines. By utilizing high-strength special steel alloys, turbine manufacturers can design lighter and more aerodynamic components, resulting in reduced overall weight and drag. Consequently, this leads to increased fuel efficiency and lower emissions, contributing to a more sustainable and environmentally friendly aviation industry. In conclusion, special steel plays a vital role in the aerospace turbine industry by delivering the required strength, durability, heat resistance, corrosion resistance, and machinability essential for the efficient and dependable operation of turbine components. Its contribution extends to improved fuel efficiency, reduced maintenance needs, and enhanced overall performance, establishing it as an indispensable material for the aerospace turbine industry.

Send your message to us

4140 Alloy Steel, 1.7225 Steel Material, SCM440 Steel Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords