Hot Rolled H13 Standard Steel Bar Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

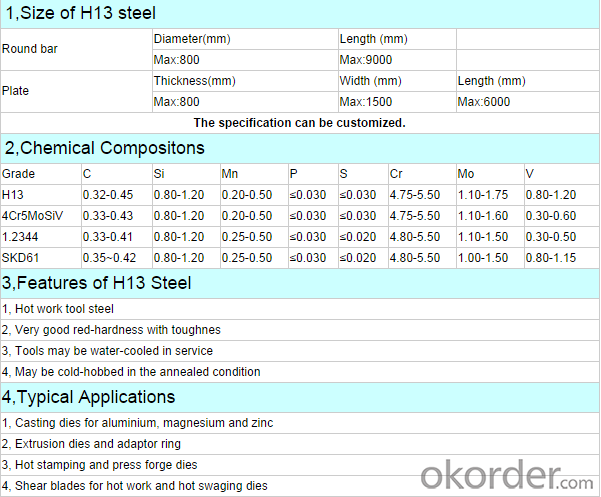

Specification

Hot Rolled H13 Standard Steel Bar Sizes

Product information:

Specifications

Songshun Hot Rolled H13 Standard Steel Bar Sizes

1.A/N/Q+T

2.Sample free

3.Black or Bright

4.Dia Max:800mm

Product show

Workshop show

Our service:

-High manufacturing accuracy

-High strength

-Small inertia resistance

-Strong heat dissipation ability

-Good visual effect

-Reasonable price

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer's trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

If you need the sample, please feel free to let me know. Any question, we will contact you ASAP!

- Q: What are the applications of special steel in the automotive supply chain?

- Special steel has various applications in the automotive supply chain. It is commonly used in the production of critical components such as engine parts, axles, gears, and suspension systems. Special steel provides high strength, durability, and corrosion resistance, contributing to improved performance and safety in vehicles. Additionally, it enables weight reduction, enhancing fuel efficiency and reducing emissions. Overall, special steel plays a crucial role in enhancing the reliability, efficiency, and sustainability of the automotive industry.

- Q: Can special steel be used in the telecommunications equipment manufacturing industry?

- Yes, special steel can be used in the telecommunications equipment manufacturing industry. Special steel, such as stainless steel or alloy steel, offers various advantages such as high strength, corrosion resistance, and heat resistance. These properties make it suitable for manufacturing various components used in telecommunications equipment, including antennas, towers, cable connectors, and enclosures. Additionally, the use of special steel can enhance the durability and performance of the equipment in challenging environments, such as extreme temperatures or exposure to harsh weather conditions.

- Q: How does special steel perform in marine environments?

- Special steel performs exceptionally well in marine environments due to its high corrosion resistance. It is specifically designed to withstand the harsh conditions of saltwater, preventing corrosion and ensuring long-term durability. Additionally, special steel has excellent strength and toughness properties, making it suitable for various marine applications, such as shipbuilding, offshore structures, and underwater equipment.

- Q: How does the composition of special steel affect its properties?

- The composition of special steel significantly affects its properties. By varying the levels of elements such as carbon, manganese, chromium, and nickel, the steel can be tailored to possess specific characteristics. For example, increasing carbon content enhances hardness and strength, while adding chromium improves corrosion resistance. Additionally, the presence of different alloying elements can influence machinability, ductility, and toughness. Therefore, the composition of special steel plays a crucial role in determining its desired properties for various applications.

- Q: What are some examples of special steel alloys?

- Some examples of special steel alloys include stainless steel, tool steel, high-speed steel, alloy steel, and maraging steel.

- Q: What are the main applications of special steel?

- Special steel is used in a wide range of industries and applications due to its exceptional properties. Some of the main applications of special steel include manufacturing of tools and machinery, construction of buildings and infrastructure, automotive and aerospace industries, energy and power generation, and medical equipment. Its high strength, corrosion resistance, heat resistance, and durability make it an ideal choice for these demanding applications.

- Q: What are the applications of tool steel?

- Tool steel has a wide range of applications due to its high hardness, resistance to wear, and ability to retain sharp edges. It is commonly used in the manufacturing of cutting tools, dies, molds, and machine components that require high strength and durability. Additionally, tool steel finds its use in the automotive, aerospace, and construction industries, where its properties are crucial for efficient and precise operations.

- Q: How does special steel contribute to the automotive sector?

- Special steel contributes to the automotive sector by offering enhanced strength, durability, and resistance to wear and tear. It is used in various critical components such as engine parts, suspension systems, and safety features, improving performance, safety, and overall reliability of vehicles. Additionally, special steel enables the development of lightweight designs, aiding in fuel efficiency and reducing emissions.

- Q: What are the thermal conductivity properties of special steel?

- Special steels, also known as alloy steels, exhibit varying thermal conductivity properties depending on their composition and specific heat treatment. The thermal conductivity of special steel generally ranges from 10 to 50 W/mK. The thermal conductivity of steel is primarily influenced by its carbon content, alloying elements, and microstructure. Carbon acts as a thermal conductor in steel, increasing its thermal conductivity. However, alloying elements such as chromium, nickel, and molybdenum can reduce the thermal conductivity of steel due to their lower thermal conductivity compared to iron. Additionally, the microstructure of special steel plays a crucial role in determining its thermal conductivity. Heat treatments such as quenching and tempering can alter the microstructure, affecting the thermal conductivity of the steel. For example, steels with a higher carbon content and a martensitic microstructure tend to have higher thermal conductivity compared to steels with lower carbon content and a ferritic or pearlitic microstructure. It is important to note that the thermal conductivity of special steel can also be influenced by other factors such as impurities, grain size, and the presence of defects. These factors can either enhance or reduce the thermal conductivity. In summary, the thermal conductivity properties of special steel can vary depending on its composition, heat treatment, and microstructure. Therefore, it is essential to consider these factors when evaluating the thermal conductivity of special steel for specific applications.

- Q: How is high-speed tool steel used in the manufacturing of drills and taps?

- High-speed tool steel is commonly used in the manufacturing of drills and taps due to its excellent hardness, wear resistance, and ability to withstand high temperatures. This type of steel is able to retain its hardness at elevated temperatures, making it ideal for cutting tools that generate heat during operation. It enables drills and taps to effectively cut through various materials, including metal and wood, while maintaining their sharpness and durability. Additionally, high-speed tool steel allows for faster cutting speeds and increased productivity in manufacturing processes.

Send your message to us

Hot Rolled H13 Standard Steel Bar Sizes

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords