Grade ASTM A36 Carbon Steel Round Bar with High Tensile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade ASTM A36 Carbon Steel Round Bar with High Tensile

Details of Grade ASTM A36 Carbon Steel Round Bar with High Tensile

Name | Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of Grade ASTM A36 Carbon Steel Round Bar with High Tensile

| Product name | ASTM A36 carbon steel round bar |

| Dimensions | 15-150mm |

| Length | 6-12m |

| Standard | ASTM,BS,GB,JIS |

| Grade | Q195 Q235 20# 45# A36 SAE1020 |

| Brand | CNBM |

| Application | Mild Steel Round Bar is used for making security grills, screens, Construction and Machine Manufacture. |

| Finish condition | hot rolled |

| Appearance | new |

| Sales mode | factory direct sales |

| Quality assurance | mill test certificate is provided, third party inspection is acceptable |

| Trade term | FOB/CIF/CFR |

| Payment term | 30%T/T in advance, balance against B/L copy;Sight irrevocable LC |

| Delivery time | Within 15-30 days after receiving original LC or deposit, also according to the quantity |

| Certification | ISO9001:2000/BV |

| Product name | ASTM A36 carbon steel round bar |

| Dimensions | 15-150mm |

| Length | 6-12m |

| Standard | ASTM,BS,GB,JIS |

| Grade | Q195 Q235 20# 45# A36 SAE1020 |

| Brand | CNBM |

| Application | Mild Steel Round Bar is used for making security grills, screens, Construction and Machine Manufacture. |

| Finish condition | hot rolled |

| Appearance | new |

| Sales mode | factory direct sales |

| Quality assurance | mill test certificate is provided, third party inspection is acceptable |

| Trade term | FOB/CIF/CFR |

| Payment term | 30%T/T in advance, balance against B/L copy;Sight irrevocable LC |

| Delivery time | Within 15-30 days after receiving original LC or deposit, also according to the quantity |

| Certification | ISO9001:2000/BV |

CNBM Introduction of Grade ASTM A36 Carbon Steel Round Bar with High Tensile

| Product name | ASTM A36 carbon steel round bar |

| Dimensions | 15-150mm |

| Length | 6-12m |

| Standard | ASTM,BS,GB,JIS |

| Grade | Q195 Q235 20# 45# A36 SAE1020 |

| Brand | CNBM |

| Application | Mild Steel Round Bar is used for making security grills, screens, Construction and Machine Manufacture. |

| Finish condition | hot rolled |

| Appearance | new |

| Sales mode | factory direct sales |

| Quality assurance | mill test certificate is provided, third party inspection is acceptable |

| Trade term | FOB/CIF/CFR |

| Payment term | 30%T/T in advance, balance against B/L copy;Sight irrevocable LC |

| Delivery time | Within 15-30 days after receiving original LC or deposit, also according to the quantity |

| Certification | ISO9001:2000/BV |

CNBM Introduction of Grade ASTM A36 Carbon Steel Round Bar with High Tensile Supplier

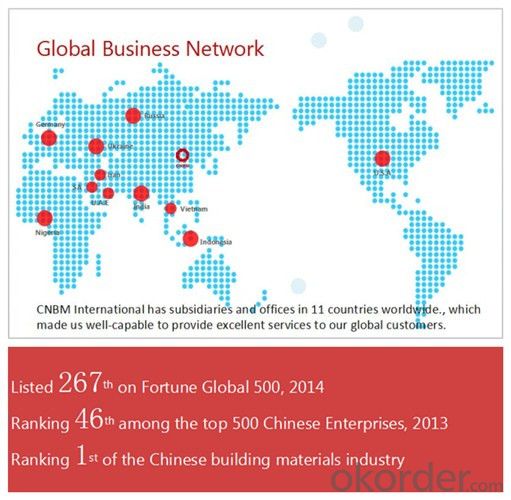

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Grade ASTM A36 Carbon Steel Round Bar with High Tensile

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: Does special steel require special machining techniques?

- Yes, special steel does require special machining techniques. Special steel, also known as tool steel or high-performance steel, has unique properties such as high hardness, wear resistance, and toughness. These properties make it more challenging to machine compared to regular or mild steel. Special machining techniques such as high-speed machining, cutting tool selection, and cooling methods are often required to achieve precise and efficient machining results with special steel.

- Q: What are the different methods of surface lapping for special steel?

- There are several methods of surface lapping for special steel, including abrasive lapping, diamond lapping, and chemical lapping. Abrasive lapping involves using an abrasive material, such as silicon carbide or aluminum oxide, to remove small amounts of material from the surface of the steel. Diamond lapping, on the other hand, utilizes diamond particles to achieve a high level of precision and smoothness. Chemical lapping involves using a chemical compound that reacts with the steel surface, selectively removing material to achieve the desired finish. Each method has its own advantages and is chosen based on the specific requirements of the steel and the desired outcome.

- Q: Can special steel be used in the oil refinery industry?

- Yes, special steel can be used in the oil refinery industry. Special steels, such as stainless steel and duplex stainless steel, offer superior corrosion resistance and high strength properties, making them suitable for various applications in oil refineries. These steels can withstand harsh operating conditions, including exposure to corrosive chemicals and high temperatures, ensuring the durability and safety of equipment and infrastructure in the oil refinery industry.

- Q: What are the different stamping grades of special steel?

- Various industries utilize different grades of special steel for stamping purposes. Some commonly used stamping grades are as follows: 1. Low Carbon Steel: This special steel grade is renowned for its exceptional formability and weldability. It finds extensive use in applications necessitating deep drawing or intricate bending. Moreover, low carbon steel is both cost-effective and readily available, making it a highly preferred choice for stamping processes. 2. High Strength Low Alloy (HSLA) Steel: HSLA steel, a type of special steel, incorporates small amounts of alloying elements like copper, nickel, or chromium. This grade offers superior strength and enhanced toughness compared to low carbon steel. It is commonly employed in automotive components, structural parts, and other applications demanding strength and durability. 3. Stainless Steel: Stainless steel is a corrosion-resistant special steel comprising a minimum of 10.5% chromium. It is frequently employed in stamping applications that require resistance against rust, staining, and corrosion. Stainless steel is available in various grades, such as 304, 316, and 430, each offering distinct levels of corrosion resistance and mechanical properties. 4. Tool Steel: Tool steel, a high-quality special steel, is specifically designed for applications necessitating resistance to wear, deformation, and high temperatures. It is commonly used in stamping dies, cutting tools, and other applications where hardness and toughness are vital. Notable tool steel grades include D2, A2, O1, and M2, among others. 5. Electrical Steel: Electrical steel, also known as silicon steel, is a special grade characterized by high magnetic permeability and low electrical conductivity. It finds application in stamping operations requiring efficient magnetic properties, such as transformers, motors, and generators. The aforementioned examples represent only a fraction of the stamping grades available in special steel. The selection of each grade depends on the specific requirements of the application, such as strength, corrosion resistance, magnetic properties, or formability.

- Q: What are the different heat-resistant grades of special steel?

- There are several heat-resistant grades of special steel, including stainless steels like 304H, 310H, and 347H, as well as nickel alloys like Inconel 600, Inconel 625, and Hastelloy C276. These grades are specifically designed to withstand high temperatures and maintain their strength and corrosion resistance even in extreme heat environments.

- Q: How does special steel perform in impact loading conditions?

- Known for its exceptional performance in impact loading conditions, special steel possesses remarkable strength, toughness, and resistance to deformation, thanks to its unique composition and manufacturing process. By effectively absorbing and dissipating energy, special steel minimizes the risk of catastrophic failure or damage when subjected to impact loading. The high strength of special steel enables it to withstand high impact forces without experiencing significant deformation or fracture, making it particularly suitable for applications where impact loading is prevalent, such as in the construction of heavy machinery, automotive components, and structural elements. In addition to its strength, special steel's toughness plays a crucial role in its performance during impact loading conditions. With excellent fracture toughness, special steel can resist crack propagation and absorb impact energy without fracturing, ensuring that it can withstand sudden and severe impacts without compromising its structural integrity. Furthermore, special steel is often subjected to treatments that enhance its resistance to impact loading conditions. Processes like heat treatment, forging, and quenching and tempering can increase the material's hardness and strength, further improving its ability to withstand impact forces. To summarize, special steel excels in impact loading conditions due to its high strength, toughness, and resistance to deformation. Its efficient energy absorption and dissipation, coupled with its resistance to fracture, make it an ideal choice for applications where impact loading is a concern.

- Q: What is the role of special steel in the construction industry?

- Special steel plays a crucial role in the construction industry as it provides enhanced strength, durability, and resistance to corrosion. It is commonly used in the construction of high-rise buildings, bridges, and infrastructure projects, where structural integrity is crucial. Special steel's unique properties enable it to withstand extreme conditions and heavy loads, ensuring the safety and longevity of construction projects. Additionally, its versatility allows for the fabrication of various components, such as beams, columns, and reinforcement bars, making it an indispensable material in the construction industry.

- Q: How does special steel contribute to the manufacturing of molds and dies?

- Molds and dies are vital tools used across industries such as automotive, aerospace, and electronics to shape materials. They require durability, resistance to wear, and the ability to withstand high temperatures and pressures. Tool steel, also referred to as special steel, possesses distinct qualities that make it ideal for molds and dies. Firstly, its high hardness allows the tools to maintain their shape and surface integrity, even with extensive use and repetitive impacts. This hardness guarantees precision and accuracy in the final product. Furthermore, special steel exhibits excellent wear resistance, crucial as molds and dies come into contact with different materials during manufacturing. This wear resistance prolongs the lifespan of the tools, reducing the need for frequent replacements and minimizing production downtime. Moreover, special steel demonstrates good toughness, enabling it to absorb and endure high impact forces without fracturing or breaking. This is particularly important for molds and dies, which often undergo significant stress during manufacturing, especially when dealing with high-pressure or extreme temperature materials. Special steel also boasts high heat resistance, enabling molds and dies to withstand elevated temperatures used in certain manufacturing processes, such as injection molding or metal forging. This heat resistance prevents warping or loss of shape, ensuring consistent and accurate production. Additionally, special steel is easily machined and shaped, allowing manufacturers to create intricate designs for molds and dies. This versatility is essential as different industries require unique tool designs to meet specific manufacturing needs. In conclusion, special steel is crucial for manufacturing molds and dies due to its high hardness, wear resistance, toughness, heat resistance, and machinability. These unique properties enhance the durability, precision, and efficiency of molds and dies, ultimately improving the quality and productivity of various manufacturing processes.

- Q: Are there any disadvantages of using special steel?

- There are several disadvantages associated with the use of special steel. To begin with, special steel tends to be more expensive compared to regular steel. This is primarily due to the additional alloying elements and heat treatments involved in its production, which contribute to the higher cost. As a result, it may not be the most cost-effective option for applications where cost is a major factor. Furthermore, special steel may have limited availability in comparison to regular steel. It is often produced in smaller quantities and may only be obtainable from specific suppliers. This can lead to longer lead times and difficulties in sourcing the required amount of special steel, particularly for large-scale projects. Additionally, the increased complexity of working with special steel can pose challenges. It may require specialized knowledge, skills, and equipment for handling and processing. If the necessary expertise or resources are not readily available, this can result in higher manufacturing costs and potential delays in production. Moreover, some special steel grades with high strength and hardness can be more prone to brittleness. This means they may be susceptible to cracking or breaking under certain conditions, especially when exposed to extreme temperatures or sudden impact loads. This limitation can be a disadvantage in applications that require high toughness or resistance to fracture. Lastly, special steel may have limited applications due to its specific properties. While it offers advantages such as corrosion resistance, high temperature resistance, or improved mechanical properties, these benefits may not be relevant or necessary for every application. Consequently, using special steel in such cases may incur unnecessary expenses without any tangible benefits. In conclusion, special steel has its drawbacks, including higher costs, limited availability, increased complexity, potential brittleness, and limited applicability. Therefore, it is crucial to carefully consider the specific requirements of a project before opting for special steel.

- Q: How does special steel contribute to the defense industry?

- Special steel contributes to the defense industry by providing materials with exceptional strength, durability, and resistance to wear, corrosion, and extreme temperatures. These properties make it ideal for manufacturing military equipment, such as tanks, aircraft, submarines, and artillery, ensuring their reliability and long service life. Additionally, special steel's high hardness and toughness make it suitable for producing armor plates and ballistic protection systems, enhancing the safety and survivability of military personnel.

Send your message to us

Grade ASTM A36 Carbon Steel Round Bar with High Tensile

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords