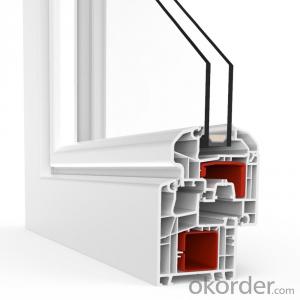

German quality Europe standard high-quality upvc window and door profiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our company was established by a German company in China in 1999. It is a professional manufacturer of U-PVC Window & Door profiles.Our brand was established in Germany in 1933 and it has a history of over eighty years. Our company is famous for excellent product design and consistent high quality. We own a good reputation in Europe and all over the world. Our company is one of the most famous Window & Door profile brand in Germany.

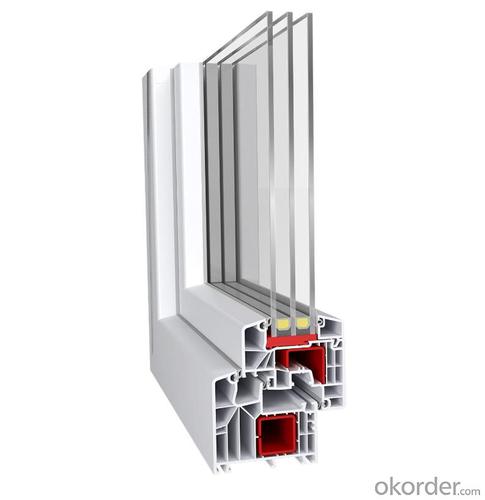

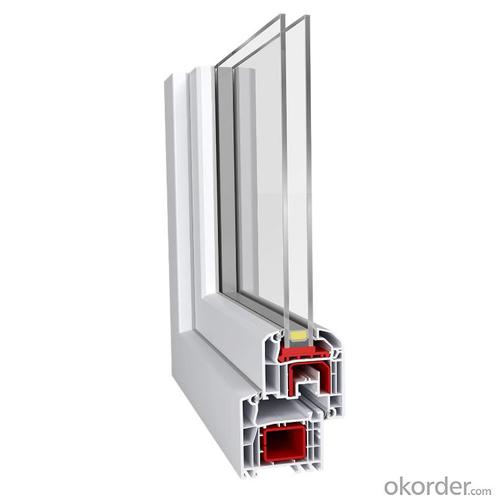

Being an expert of German quality upvc profiles, our products strictly follow European standard unremittingy, for which we stick to to products quality at every stage of manufacturing process. To attain consistent quality, Our facility is equipped with technologically superior German

equipment.We have cooperation with international well-known enterprises, such as US DuPont, Renolit, SABIC, which provides high quality color products for construction windows and doors.

We offer 6 products series: Lotos, Komfort, Peony, Edelweiss, Contour and Elegance, comprising 60mm, 70mm, 88mm, 107mm, 108mm and 127mm profile for sliding and combined windows and doors. We provide high-UV resistant white profiles, color coated profiles, colored body profiles.

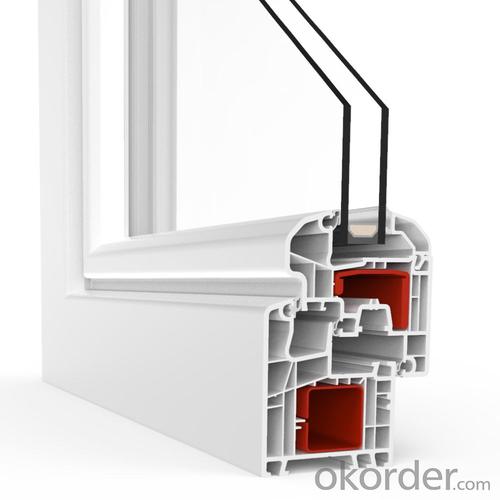

uPVC Sliding System

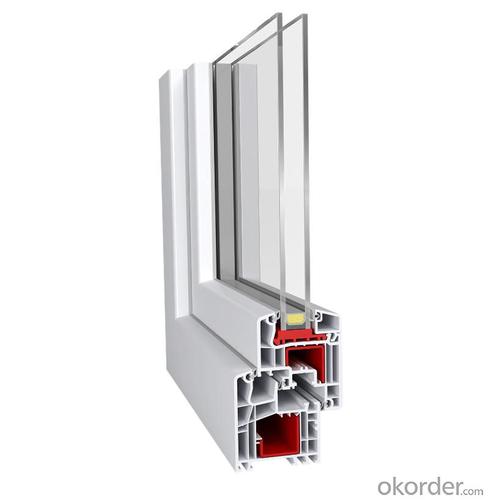

uPVC Casement System

Window Sliding System – (60,70,88,107,108,127mm)

Suitable for all weather conditions.

High weatherability, high malleability, pollution-resistant

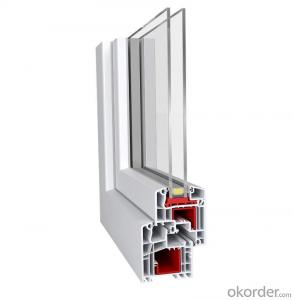

Window Casement System –(60,70,88,107,108,127mm)

Suitable for all weather conditions.

High weatherability, high malleability, pollution-resistant

Door Sliding System – (88,107,108,127mm)

Suitable for all weather conditions.

High weatherability, high malleability, pollution-resistant

Door Casement System – (88,107,108,127mm)

Suitable for all weather conditions.

High weatherability, high malleability, pollution-resistant

Sliding System

Window Sliding System – (60,70,88,107,108,127mm)

Suitable for all weather conditions.

High weatherability, high malleability, pollution-resistant

Door Sliding System –(60,70,88,107,108,127mm)

Suitable for all weather conditions.

High weatherability, high malleability, pollution-resistant

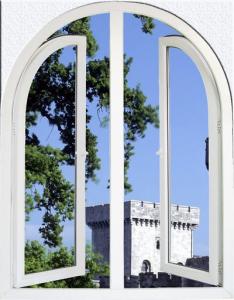

Special Windows

Tilt & Turn Window System (88,107,108,127mm)

Suitable for all weather conditions.

High weatherability, high malleability, pollution-resistant

Combination Doors

Slide & Fold Door System – (88,107,108,127mm)

Suitable for all weather conditions.

High weatherability, high malleability, pollution-resistant

For more details, please contact us.

- Q: Plastering and doors and windows installed in the order

- Usually first fitted with a door cover and window cover, and then plastering the wall, then install the door and window.

- Q: Paving mosaic construction process

- With the high-end mosaic paving, paste construction is simple and convenient, it is characterized by not corrosion the bottom and prevent oxidation black, strong sticky, and suitable for flooding environment.

- Q: Plastic window is not also called plastic doors and windows, how to explain is a kind

- Is a kind of plastic doors and windows without pure meaning.

- Q: My house is duplex building, fourth floor, the floor is 4.5 meters high, the window is from the top to the windowsill 4 meters high, 4.5 meters wide, is the aluminum plastic, the middle of a standing aluminum plastic column, width 5 cm Maintenance team before the repair of shaking, especially the performance of the wind is very obvious, the middle of the window shaking the trip is about 10 cm, usually hand effortless push the windows on the shaking. Will the windows there is no national standard, so you can shake the windows

- The national standard of the specific values do not know, but the shaking of 10 cm absolutely unqualified, like your home so big windows should belong to the curtain wall structure, and ordinary window frame can not afford, there are curtain wall frame, and the window construction unit to Responsible for the design, unless you are asking to do so, then he must meet the technical requirements of the curtain wall, and the glass block is greater than 1.5 square meters to use tempered glass, curtain wall requirements than ordinary windows a lot of strict.

- Q: Do the doors and windows installed in the hole before the installation of metal sub-frame, and then install the main frame, the main frame and sub-frame between the cracks to how to deal with? More

- Fire agent, also known as sealant, specifically do this with

- Q: Plastic door and window frame dirty not clean how to do?

- You want to see what is above, we give the program! Is it going to clean up or intend to change a window!

- Q: Broken bridge doors and windows series 60 what meaning

- Broken bridge doors and windows 60 series refers to the aluminum alloy profiles with insulation profiles and doors, window frame thickness of the size of 60mm doors and windows. According to the "aluminum alloy doors and windows" GB / T8478-.1.4 product series to the door, window frame in the depth of the design of the hole size - door, window frame thickness of the structural size (code C2, in millimeters) division. Door, window frame thickness of the size of the construction in line with 1 / 10M (10mm) of the number of building sub-series of values for the basic series; basic series by 5mm into the value of the auxiliary series. Door, window frame thickness When the construction dimension is less than a basic series or auxiliary series value, mark the product series at the previous level less than the series value. (Such as the door, window frame thickness of the structure size of 72mm, the product line for the 70 series; door, window frame thickness of the structural size of 69mm, the product line for the 65 series) so 60 series refers to the door, Depth direction of the design size - door, window frame thickness of the structure size of 60mm broken bridge refers to the aluminum alloy profiles with insulation profiles.

- Q: Rough room provided by the heat of the aluminum alloy doors and windows frame color is dark green, hoping to change to white or black. Do not know what method can be achieved? 1, paint? Will it fall off? 2, see someone online that can change the color foil, do not know what kind of film? More

- First of all, I would like to know, you are not to change the color under the window and then, if so, you can re-processing the surface of the multi-profile, if not, feel difficult to paint, 135 + + + + + + "that kind of paint do not know okay

- Q: Aluminum alloy doors and windows frame how to tear the film

- Highest heat treatment! Remember, do not scratch with a blade!

- Q: Doors and windows should be used to set aside the hole to install, do not use the edge of the installation side of the mouth or the first installation of the construction method What is the meaning, which can explain in detail

- Plastic window is built brick and brick brick,

Send your message to us

German quality Europe standard high-quality upvc window and door profiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords