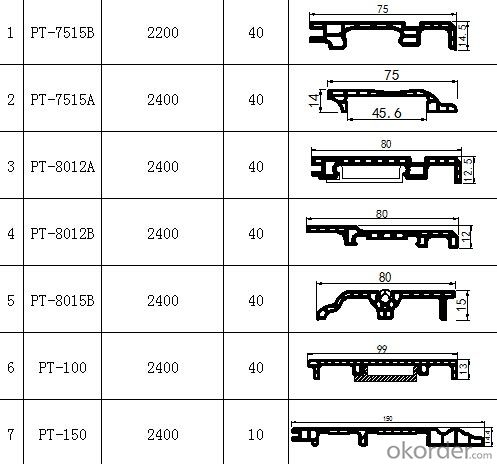

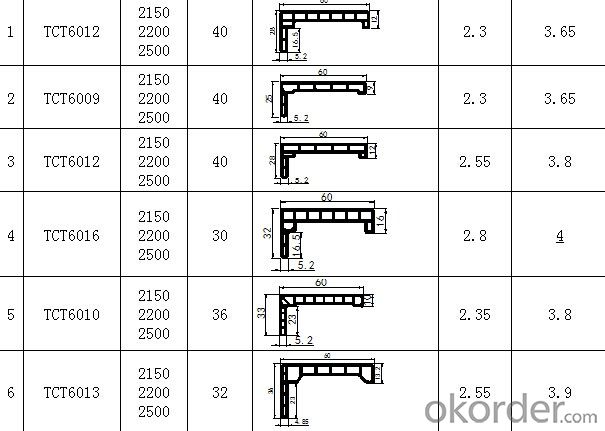

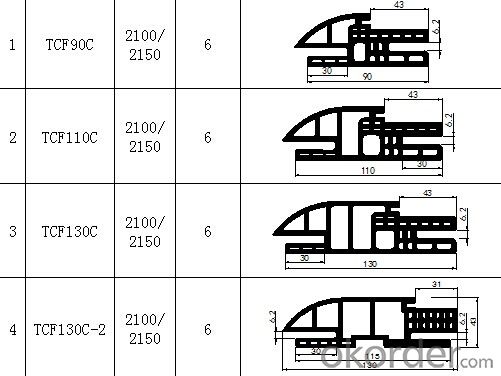

Good Quality PVC Door Frame Accessory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Our factory is divided into twelve production lines. We use production equipment from Germany including mixers and double screw rod extruding machines. Our monthly capacity is 500 tons of wood plastic composites--80% of which we export.

We have an R&D department with 5 engineers who have an average of 10 years of experience. They research and develop our equipment, including the mixer, assembly line, QUV experiment meter, multi-purpose impact reflectoscope, dresser and knurling machine. We develop at least one new product every month and can prepare OEM samples for you with a lead time of one month.

We have a QC department with five engineers who have an average of four year's experience. They examine products before export using reflectosopes and ensure our facilities conform to ISO 9001 and ISO 14000 certification standards. The products was tested by third party(INTERTEKS, SGS), meet REACH’S regulations.

Our company adheres to “Quality first, Customer first” philosophy, in line with “The good faith management” principle of service, looking forward to cooperating with you.

- Q: Red TV background wall, white wall, juvenile window frame with what color curtains nice, living room, bedroom, son room

- The whole two layers, one layer is the kind of curtains of jujube silk weave, a white flower with white flowers like silk curtains. Bedroom can use the same, his son room to let him pick, this will be like

- Q: Sliding doors and windows to prevent shedding measures which

- In fact, when you usually use the push and pull the general will not fall off, is the usual use of the method.

- Q: Paving mosaic construction process

- Double gull nostalgic mosaic can be used for indoor and outdoor floor and wall decoration. For construction paving, the most critical job is to prepare the surface of the site. Tiles must be in the horizontal and vertical angle are accurate and accurate paving, so as to avoid problems. Paving the surface must be clean and dry. Paving materials: the market has a professional mosaic tile adhesive and sealing agent, there are two-in-one tile glue. Color is also a variety of points, according to different needs with the use of cement and sealant. The most widely used is white and black. Paving tools: grouting floating, large bucket, V-shovel, hammer, small bucket, pliers. Paving steps: 1. In the vat inside the mixed powder-like mosaic tile glue, stirring at the same time by adding water until peanut butter to achieve similar viscosity. 2. In the construction of the wall, then use the v-type shovel. Each post a paste From the middle of the patch area to start paving out. In the wall with the horizontal line and the vertical line for the mark, you can make the gap between each paste evenly. Hand the appropriate force to the mosaic into the tiles inside, so that mosaic and ceramic tile full contact. 3. Paste finished or close the mosaic, you need to paste a paste on the match mosaic. With a piece of wood and a hammer, gently tapping to adjust the position of the mosaic. Need to pay special attention to the edge and connection of each mosaic. 4. If necessary, adjust the mosaic position in time before the mud is dry. 5. Allow the mud to have a 24 hour posture before filling. 6. Dry the sealant for 10-20 minutes, then gently wipe the mosaic surface with a piece of wet sponge. 7. Finally, wipe with a piece of lint-free cloth out of the mosaic surface of the remaining cement and caulking agent.

- Q: Plastic window is how to do ah?

- First make plastic frame, and then insert the steel inside, so called steel.

- Q: Broken bridge aluminum screens how to go up

- The first step: the yarn box, air slot, bottom assembled, and then use six screws to twist it to make it a square box. The second step: the screen on the installation site, pay attention to the left and right air duct and the door window frame to the left and right symmetry, bottom position from the door frame frame to be about 5cm lower, put the left and right with the clip, Doors and windows so that they can not move. The third step: with electric drill with 3.2mm drill bit in the door window frame inside the puncture. Step 4: According to the need in the left and right air trough and below the bottom of the corresponding place marked with 6 to 14 eyes, and then screw the screw is installed. Installation Notes: 1, the yarn box to be vertical fixed, broken bridge aluminum doors and windows at both ends to occupy the upper and lower border prevail. 2, up and down the slide with the location of the parallel box fixed, to avoid skid inside and outside skew. 3, the base position to close the pull beam, placed in the sliding window swoop to close and then draw lines and fixed, so as not to fixed position too far or too far. 4, if the parts of the fixed nail is too long, will prevent the normal sliding sliding window slick, broken bridge aluminum doors and windows can be self-nail with a shears cut short can be.

- Q: Do you have the order to install the floor and window? What order is it right?

- The door frame is finally installed, or else the small area below the door frame can not be built

- Q: Living in high-rise window how to install screens

- Inside the window, then the screen installed on the outside, with stealth Shachuang, with the time to open the window to open the screen, do not use the words off the window window

- Q: Rough room provided by the heat of the aluminum alloy doors and windows frame color is dark green, hoping to change to white or black. Do not know what method can be achieved? 1, paint? Will it fall off? 2, see someone online that can change the color foil, do not know what kind of film? More

- First of all, I would like to know, you are not to change the color under the window and then, if so, you can re-processing the surface of the multi-profile, if not, feel difficult to paint, 135 + + + + + + "that kind of paint do not know okay

- Q: What are the welding principles for steel doors and windows? Whether the vertical or vertical vertical welding, corner and doors and windows are used in what way to welding. More

- Google check ,,, comfort. The The The

Send your message to us

Good Quality PVC Door Frame Accessory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches