Geotextile for Soil Stabilization - Polyester Fiberglass Geotextile Fiberglass Roofing Tissue

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

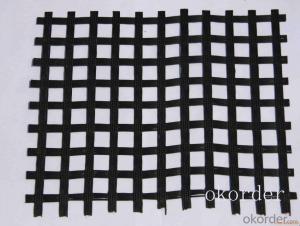

Polyester Fiberglass Geotextile fiberglassroofing tissue

It 's a new composite fiberglass cracking-resistant material, made of fiberglass and PET fiber by

Special process.

Specification ofPolyester Fiberglass Geotextile fiberglass roofing tissue:

Tensile strength: 5kN/m - 8kN/m

Property of PolyesterFiberglass Geotextile fiberglass roofing tissue:

I. Delaying the reflective crack

2. Provide super waterproof layer

3. Could be completely crushed and used for road regeneration

4. No shrink. Fiberglass geotextile has the ability of no deformation and noshrink under high

Temperature construction environment

5. No stretch. Fiberglass geotextile does not stretch deformation duringinstallation prog ress

Application of PolyesterFiberglass Geotextile fiberglass roofing tissue:

I. Cement concrete pavement reconstruction

2. Old road reconstruction and extension project

3. Asphalt concrete surface

4. Municipal road engineering with cover project

5. Semi-rigid base shrinkage crack disposal

6. Bridge deck waterproof layer

- Q: How do geotextiles help with sediment control in construction sites?

- Geotextiles help with sediment control in construction sites by acting as a barrier that prevents soil erosion and sediment runoff. They are placed on the ground or slopes to stabilize the soil, allowing water to permeate through while trapping sediment particles. This helps to prevent sediment from being carried away by stormwater runoff, thereby reducing the risk of water pollution and ensuring compliance with environmental regulations.

- Q: How do geotextiles help with vegetation establishment in landscaping projects?

- Geotextiles help with vegetation establishment in landscaping projects by providing a stable and favorable environment for plants to thrive. They prevent soil erosion, retain moisture, and control weed growth, which ultimately promotes healthy root development and successful establishment of vegetation.

- Q: What are the different types of geotextile installation equipment?

- Some common types of geotextile installation equipment include geotextile rollers, geotextile stitchers, geotextile spreaders, geotextile staplers, and geotextile tensioners. These tools are used to efficiently and effectively install geotextiles in various applications such as erosion control, soil stabilization, and drainage systems.

- Q: Can geotextiles be used for reinforcement of railway tracks?

- Yes, geotextiles can be used for reinforcement of railway tracks. Geotextiles are durable and can enhance the stability and load-bearing capacity of the track by distributing and dissipating loads, reducing settlement and deformation, and improving overall performance.

- Q: What are the key considerations for geotextile installation in areas with high seismic activity?

- The key considerations for geotextile installation in areas with high seismic activity include selecting a geotextile material that can withstand strong ground shaking, ensuring proper anchoring and securing of the geotextile to prevent displacement during seismic events, evaluating the potential for liquefaction and designing appropriate drainage systems to mitigate its effects, conducting thorough site investigations to understand the soil conditions and potential for ground movement, and regularly monitoring and inspecting the geotextile installation for any signs of damage or failure due to seismic activity.

- Q: Do you have a drainage board and a geotextile?

- How many dishes? Drainage board and geotextile a square need about 15 yuan cost, their trade-off

- Q: Can geotextiles be used for drainage purposes?

- Yes, geotextiles can be used for drainage purposes. They are often used to enhance the drainage capacity of soil by allowing water to flow through while preventing soil erosion. Geotextiles can be employed in various applications such as road construction, landfills, and agricultural fields to improve drainage and prevent waterlogging.

- Q: How do geotextiles help with subgrade stabilization in road construction?

- Geotextiles help with subgrade stabilization in road construction by acting as a barrier between the subgrade and the overlying layers of the road. They distribute and reduce the load from the traffic, preventing the subgrade from becoming weak or uneven. Additionally, geotextiles can separate different soil layers, preventing them from mixing and improving the overall stability and strength of the road.

- Q: How do geotextiles contribute to the performance of geocell systems?

- Geotextiles play a crucial role in enhancing the performance of geocell systems. They are installed within the geocell walls and act as a stabilizing agent by providing reinforcement and preventing soil migration. Geotextiles distribute the load evenly, increase the overall strength of the system, and improve the overall stability and longevity of the geocell structure. Additionally, geotextiles can also act as a filtration layer, allowing water to pass through while preventing soil particles from clogging the system, thereby maintaining its efficiency and functionality.

- Q: Are geotextiles environmentally friendly?

- Yes, geotextiles are environmentally friendly. They are made from natural or synthetic fibers that are biodegradable and do not release harmful substances into the environment. Geotextiles also help to prevent soil erosion, promote vegetation growth, and improve water quality, making them a sustainable solution for various environmental applications.

Send your message to us

Geotextile for Soil Stabilization - Polyester Fiberglass Geotextile Fiberglass Roofing Tissue

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords