4 Oz Needle Punched Nonwoven Geotextile for River Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Discription:

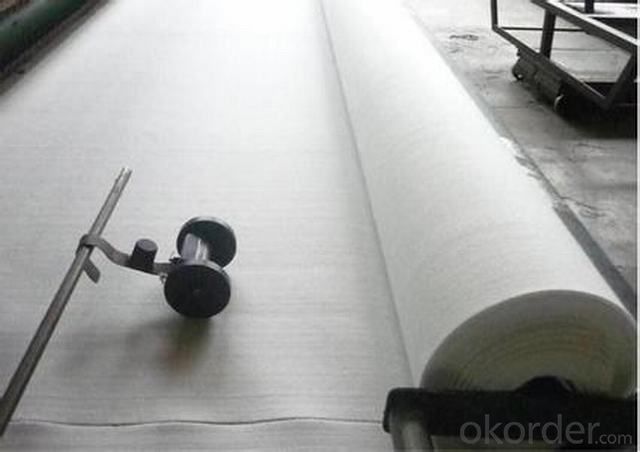

OKorder is offering high quality Needle Punched Nonwoven Geotextiles for River Construction at great prices with worldwide shipping.

Our Geotextiles are available in a wide range of types and dimensions. Our supplier is a world-class manufacturer and our products are utilized

the world over, with OKorder annually supplying a full range of products to European, North American and Asian markets.

We provide quotations within 24 hours of receiving an inquiry and guarantee a competitive price.

Product Applications:

OKorder's Needle Punched Nonwoven Geotextile for River Construction and related products have many applications and currently

support many civil engineering applications including roads, airfields, railroads, embankments, retaining structures, reservoirs, canals, dams,

bank protection, coastal engineering and construction site silt fences or geotubes.

Product Advantages:

OKorder's Geotextiles are made from polypropylene staple fibers on cross-laying and needle punch equipment.

Our advanced production methods result in Geotextiles that are very high strength, have excellent elongation and high biological tolerances.

Main Product Features:

· Acid and alkali resistant

· Erosion aging resistant

· Excellent filtration

· Easy installation

· Low cost

Product Specifications:

Material: PP / PET

Weight: 100g/m² – 1500g/m²

Length: 50m – 100m/roll (Per request)

Width: 1m – 8m

Certification: CE / ISO9001

Color: Black, white, grey

Manufacturing method: Nonwoven / Woven

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What are the differences between Nonwoven and Woven Geotextiles?

A3: Nonwoven Geotextiles are made of directionally or randomly orientated fibers, filaments or other elements, mechanically and/or thermally and/or adhesively bonded Woven Geotextiles are produced by interlacing two or more sets of yarns, fibers, filaments, tapes or other elements.

Q4: What are the differences between needlepunched and thermally bonded Nonwoven Geotextiles?

A4: Needlepunched Geotextiles are produced by entangling continuous or short fibers by needles. This so called mechanical bonding can be improved by additional thermal bonding thermally bonded Geotextiles are produced by bonding randomly or directionally orientated fibers using thermal treatment.

Q5: Which role does the polymer play in the properties of the Geotextile?

A5: Different polymers are used for the production of Geotextiles. The selection of a polymer depends mainly on properties like melting point, density, melt flow index and more that influence the different production processes. Usually the polymer is modified using additives and stabilizers in order to improve the characteristics. It is the final manufactured product that is of primary interest to the end user.

Q6: What is the difference between Geotextiles and Geosynthetics?

A6: Geosynthetics is the generic term for products where at least one component is made from a synthetic or natural polymer used in contact with soil and/or other materials in geotechnical and civil engineering applications. Geotextiles are planar, permeable, polymeric textile products and are one type of geosynthetics.

- Q: Concrete panel shop asphalt do not add geotextiles

- Plus no geotextile cloth according to the design requirements and construction specifications. Generally require high road construction need to lay geotextile. Geotextile manufacturers to answer your questions

- Q: Can geotextiles be used for soil reinforcement in embankments?

- Yes, geotextiles can be used for soil reinforcement in embankments. Geotextiles are often used in civil engineering projects to enhance soil stability and prevent erosion. In embankments, they can be placed between soil layers to distribute loads, improve drainage, and increase the overall strength and stability of the structure.

- Q: What is the purpose of using geotextiles in construction projects?

- The purpose of using geotextiles in construction projects is to improve the stability, durability, and overall performance of the construction site. Geotextiles act as a barrier against soil erosion, provide filtration and drainage capabilities, and enhance soil reinforcement. They also help in the separation of different soil layers, preventing contamination and maintaining the integrity of the project.

- Q: How are geotextiles tested for quality assurance?

- Geotextiles are tested for quality assurance through a series of standardized tests and evaluations. These include physical properties testing such as tensile strength, tear resistance, and puncture strength, as well as hydraulic properties testing like permeability and filtration efficiency. Additionally, durability and chemical resistance tests are conducted to ensure the geotextiles can withstand long-term exposure to various environmental conditions. These rigorous quality assurance measures help to determine the performance and suitability of geotextiles for specific applications.

- Q: 250 grams of two cloth a film 0.8 thick geotextile what price

- 250 grams of two cloth a film 0.8 thick geotextile per square meter between about 10 yuan -13 yuan, the current price is the lowest in recent years.

- Q: How to judge the geotextile test results are reliable

- Different methods, different detection methods will lead to different results. But you can get the authority of the provincial inspection hall, do the test report

- Q: Can geotextiles be used in underground construction projects?

- Yes, geotextiles can be used in underground construction projects. They are commonly used to separate different soil layers, provide filtration, drainage, and erosion control. Geotextiles can also enhance the stability and strength of the underground structures by providing reinforcement and preventing soil movement.

- Q: Where to sell black geotextile prices

- Those who produce geotextile manufacturers are selling black geotextile. Black geotextile according to the use of a lot of specifications, the price difference is very large. The weight per square meter between about 50-1000g grams, the weight of different unit price is different, the inquiry directly asked how much money per ton. According to the use of distinction between the current market price per ton price between 5,000 yuan - yuan. For the conservation, isolation, insulation of the geotextile the cheapest. In the 5000 yuan / ton between. For the filter, soft base treatment, slope protection, reinforced decoration, and other purposes of the black geotextile most expensive in - yuan / ton. The same black color, but different uses, production processes and production costs are not the same.

- Q: Are geotextiles suitable for use in coastal erosion control?

- Yes, geotextiles are suitable for use in coastal erosion control. Geotextiles are commonly used in coastal areas to stabilize the soil, prevent erosion, and protect the coastline from wave action. They are effective in reducing soil erosion by filtering sediment and allowing water to permeate through while preventing the loss of soil particles. Geotextiles also provide protection against storm surge and tidal forces, making them a valuable tool in coastal erosion control efforts.

Send your message to us

4 Oz Needle Punched Nonwoven Geotextile for River Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 1500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords