Geotextil Panel - Never Run Multiple-Textile-Multiple-Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

More cloth membrane welding effect

More cloth membrane construction effect

Composite geomembrane

Products overview:

Shandong yongrun composite geomembrane is by geotextiles length (acupuncture geotextile, woven wire, plastic weaving cloth geotextile, etc) and high polymer materials (HDPE membrane, LDPE film, EVA film, etc.) two or more material after rolling, hot melt compound and into the geosynthetic materials.

Properties:

My company product money more than 10 years experience in compound earthwork film production, solve the breadth of similar products unevenly, film thickness not divide evenly, composite produce more of the holes, the defects such as factory every piece of product passed strict inspection, make the product is in engineering application of maximum plays its role. Money has developed for I also have two kinds of hot pressing, composite process of the production enterprise, the product to seven meters wide, and the narrow compared with the prices of similar products, reduce the juncture, reduce project cost, shorten the construction period, and at the same time reducing the juncture caused by the improper hidden trouble. Compound earthwork film money instead of particle materials with geotextiles as geomembrane cover to protect the geomembrane impervious layer are not damaged, reduce the cushion layer of particle size gradation requirement, and can play drainage effect.

Money compound earthwork film friction coefficient is big, can prevent the cover of sliding, than pure HDPE film, compound earthwork film of non-woven fabrics have larger friction coefficient, composite geomembrane can make the slope than increase reduce cover an area of an area.

Compound earthwork film money tensile, rent, against the broken, puncture of mechanics high strength. Compound earthwork film have certain othermeasuring deformation, on the bottom cushion the convex defect of stress transmission spread quickly, strain capacity is stronger.

Compound earthwork film othermeasuring and contact surface soil of pore pressure and "easy to lift force float. Money is of certain compound earthwork film heat preservation effect, reduce the soil freezing expansion to the destruction of the geomembrane, thus reduce soil deformation.

Compound earthwork film using money embedded laid, a good anti-aging performance, reduce the engineering maintenance, maintenance. Money composite geomembrane laid construction is simple, reduce traffic volume and cut down engineering cost, shorten the construction period. Product categories:

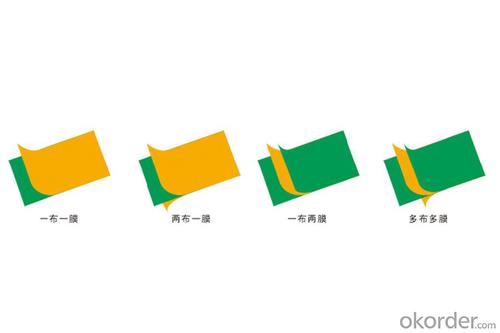

A film and a cloth othermeasuring cloth: 100 1000 g/m2 film thickness: 0.2 2.0 mm;

Money a film and two cloth cloth: 80 600 g/m2 film thickness: 0.2 2.0 mm;

A cloth, two film othermeasuring cloth: 100 1000 g/m2 film thickness: 0.2 0.8 mm;

More than money more than cloth cloth: the film 100 1000 g/m2 film thickness: 0.2 0.8 mm;

The product specification: wide: 2-7 meters; Weight: 300 2600 g/m2

Use scope:

Composite geomembrane because of their good drainage, excellent plane seepage control characteristics and tensile, rent, against the broken, puncture of mechanics characteristic of high strength, and can be widely used in:

1, JiangDi, lake dam, tailings DAMS and reservoir area, water diversion channel, storage of lead liquid pools (pit, mine);

2, the subway, the basement and tunnel, tunnel lining of seepage control;

3 and roadbed and other foundation saline seepage control;

4, before dam dike, horizontal impervious blanket should be taken, the foundation vertical anti-seepage layer, construction cofferdam, waste field;

5, sea water, fresh water farms;

6, highway, the highway, railway roadbed, expansive soil and the waterproof layer of collapsible loess;

Construction method: A, construction attention:

1, shall be used to use embedded, cover thickness not less than 30 cm;

2, the seepage control system should have: cushion and impervious layer, layer, layer to instruct the transition;

3, soil to solid uneven subsidence, avoid, crack, seepage control within the scope of the grass roots, to remove. And membrane surface laid the sand or small particle size of clay layer for protection.

4, when laying compound earthwork film don't pull it too tight, embedded into soil at both ends of corrugated is better, especially things with rigid materials anchor, should be left expansion amount must be.

5, construction, should avoid stones, heavy direct hit in the compound earthwork film, best edge construction, edge laid membrane, edge covered a protective coating.

Second, juncture:

1, the laid of the compound earthwork film:

A, cleaning the compound earthwork film laying face asks matrix level off, can't have uneven, can not have the sharp objects, such as stones, iron wire, lags, etc, to MieCaoJi spray for weeds.

B, composite geomembrane best direction laid, while the must not taut, should be left expansion amount must be, in order to adapt to the matrix deformation.

C, composite geomembrane both sides are reserved a certain width PE film and PE membrane adhesive layer, laid to adjust each unit when compound earthwork film to, in order to two units of welding compound earthwork film.

D, composite geomembrane laying good, want to live with ShaDai pressure, in case the pneumatic, influence the next step compound earthwork film the edge of the welding.

2, the compound earthwork film welding:

A, for laying good composite geomembrane, edge joint requirements cannot have dirt, water, dust, etc.

B, before welding seams good to adjust the two images edge PE film, the single lap certain width, and level off, without folds.

C, welding, the company sent technical personnel responsible for welding or technical guidance, welding, using a special automatic welding welding double crawling.

- Q: How do geotextiles improve the performance of geosynthetic clay liners?

- Geotextiles improve the performance of geosynthetic clay liners by acting as a cushioning layer, preventing the direct contact between the clay liner and the surrounding soil, which helps to reduce the risk of puncture or damage to the liner. Additionally, geotextiles enhance the drainage capabilities of the clay liner by allowing water to pass through while retaining the clay particles, which improves the liner's hydraulic conductivity and overall performance in terms of filtration and containment.

- Q: How many meters from the river pipe trench construction using geotextile reinforcement

- River slope protection, etc. can use my professional production of geotextile products. Thank you

- Q: Can geotextiles be used in golf course construction?

- Yes, geotextiles can be used in golf course construction. They are often used to provide erosion control, soil stabilization, and drainage solutions in areas such as golf course bunkers, greens, fairways, and tee boxes. Geotextiles can help prevent soil erosion, improve water drainage, and enhance the overall durability and maintenance of golf course surfaces.

- Q: Geotextile types and role of geotextiles which types, respectively, what role, filament geotextile, short geotextile, composite geotextile, respectively, what role? More

- Geotextile types and role of geotextiles which types, respectively, what role, filament geotextile, short geotextile, composite geotextile, respectively, what role? More

- Q: What are the different guidelines for geotextile installation in erosion control projects?

- There are several guidelines that need to be followed for geotextile installation in erosion control projects. Firstly, the geotextile must be placed on a properly prepared surface to ensure maximum effectiveness. The fabric should be tightly stretched and secured to prevent any movement or shifting. Additionally, the edges of the geotextile should overlap and be properly sealed to create a continuous barrier. It is also important to avoid any wrinkles or folds in the fabric as these can compromise its performance. Finally, regular inspection and maintenance should be conducted to ensure the geotextile remains intact and functional over time.

- Q: Why do you want to add 1 to the amount of geotextile

- There are overlapping area and loss, I am specializing in the production of geotextiles

- Q: Waterproof geotextile how much money per square meter

- This material has a lot of different quality, there are many different requirements, the price from dozens of pieces to more than 100 pieces between.

- Q: Can geotextiles be used for filtration purposes?

- Yes, geotextiles can be used for filtration purposes. They are permeable fabrics that can effectively filter out fine particles while allowing water or other fluids to pass through. This makes them suitable for applications such as erosion control, drainage systems, and preventing soil contamination.

- Q: Are geotextiles resistant to fire?

- Yes, geotextiles can be made resistant to fire through the use of specific materials and treatments.

- Q: National standard geotextile and non - standard how to distinguish

- Detection data are different. Appearance quality is also more obvious.

Send your message to us

Geotextil Panel - Never Run Multiple-Textile-Multiple-Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords