Geosynthetic Clay Liner(GCL) for Anti-seepage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

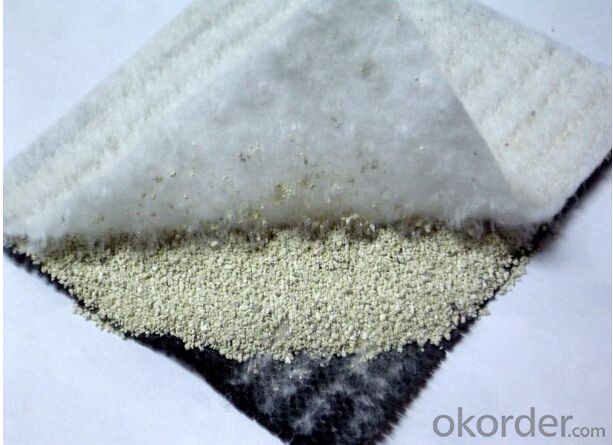

sodium Bentonite Geosynthetic Clay Liner(GCL) for anti-seepage

1,Introduction

GCL is a new geosynthetics. It is graded by a natural sodium bentonite particles and corresponding additive mixed together, By special technology and equipment, the bentonite particles between two layers of geotextile fixed, made of waterproof blanket, with all the characteristics of both the geotextile material, but also has excellent water (infiltration) performance.

2,Feature

(1) A permanent waterproof performance, and excellent water seepage performance, impermeability hydrostatic pressure up to 1.0MPa above, permeability coefficient 5 *10-9cm / s. Because the Department of Natural sodium bentonite inorganic materials, even after a long time or the surrounding environment changes, aging or corrosion does not occur.

(2) Has all the characteristics of geotextile material, such as separation, reinforcement, protection, filtration, simple construction and unrestricted construction environment temperature below 0 0 C also be construction. Just when construction GCL waterproof blanket tile on the floor, when the elevation or slope construction, with nails and washers to secure it, as required, can overlap.

(3) Easy to repair; Even after water (seepage) end of construction, such as waterproof layer accident damage, as long as the site of the damage to be a simple fix, can ever regain perfect waterproof performance.

(4)green: Bentonite is a natural inorganic material, harmless, non-toxic, no particular impact on the environment, with good environmental performance.

(5) simple construction period is short: and other waterproof materials, the construction is relatively simple, does not require heating and paste. Product width up to 6 meters, with international geotextile (film) to match the size, greatly improving the efficiency of construction.

(6) Integrated waterproof materials and objects: When sodium bentonite water, with 20-28 times the capacity expansion, even if the concrete structure vibration and settlement, bentonite GCL can repair cracks in the concrete surface less than 2mm.

3,Application

(1)Municipal engineering, underground engineering subways, buildings and roofs reservoir seepage.

(2)Environmental sanitation, solid waste landfills, sewage treatment plants, industrial waste.

(3)water, rivers, lakes and reservoirs dam seepage, plugging, reinforcement.

(4)Garden artificial lake golf course pond seepage and so on.

(5)Petrochemical, mining and other areas of engineering seepage, leakage, etc.

4,Specification of Geosynthetic Clay Liner(GCL) for anti-seepage

PROPERTIES | Test Method | Typical Value |

BENTONITE PROPERTIES | ||

Bentionite Swell Index | ASTM D 5890 | ≥24ml/2g |

Bentionite Fluid Loss | ASTM D 5891 | ≤18ml |

Finished GCL PROPERTIES | ||

Bentionite Mass/Unit Area | ASTM D 5993 | ≥3.6kg/sq.m |

Peel Strength | ASTM D 6496 | ≥400N/m |

Grab Strength | ASTM D 6768 | ≥6kN/m |

Thickness | ASTM D 5199 | ≥6mm |

Permeability | ASTM D 5084 | ≤5.0×10-11m/sec |

Index Flux | ASTM D 5887 | ≤1.0×10-8m3/m2/sec |

Geotextile PROPERTIES | ||

Non-Woven Geotextile Mass | ASTM D 5261 | ≥200g/sq.m |

Woven Geotextile Mass | ASTM D 5261 | ≥110g/sq.m |

ROLL DIMENSIONS | ||

Width | Normal | 5.8m |

Length | Normal | 30m |

Package | Normal | PE Film |

PROPERTIES | Test Method | Typical Value |

BENTONITE PROPERTIES | ||

Bentionite Swell Index | ASTM D 5890 | ≥24ml/2g |

Bentionite Fluid Loss | ASTM D 5891 | ≤18ml |

Finished GCL PROPERTIES | ||

Bentionite Mass/Unit Area | ASTM D 5993 | ≥3.6kg/sq.m |

Peel Strength | ASTM D 6496 | ≥400N/m |

Grab Strength | ASTM D 6768 | ≥6kN/m |

Thickness | ASTM D 5199 | ≥6mm |

Permeability | ASTM D 5084 | ≤5.0×10-11m/sec |

Index Flux | ASTM D 5887 | ≤1.0×10-8m3/m2/sec |

Geotextile PROPERTIES | ||

Non-Woven Geotextile Mass | ASTM D 5261 | ≥200g/sq.m |

Woven Geotextile Mass | ASTM D 5261 | ≥110g/sq.m |

ROLL DIMENSIONS | ||

Width | Normal | 5.8m |

Length | Normal | 30m |

Package | Normal | PE Film |

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: In addition to cement, but also add gelling agent

- The development of cementitious materials has a long history, people use the earliest cementitious material - clay to wipe the simple building. Then there are cement and other building materials and cementitious materials have a great relationship.

- Q: Are earthwork products resistant to soil settlement and subsidence?

- Yes, earthwork products are generally designed to be resistant to soil settlement and subsidence. These products are specifically engineered to provide stability and durability in various soil conditions, helping to minimize the risk of settlement and subsidence issues. However, it is important to ensure proper installation and maintenance to maximize their effectiveness.

- Q: How do earthwork products contribute to wildlife habitat creation?

- Earthwork products such as berms, ponds, and wetlands play a crucial role in creating and enhancing wildlife habitats. These structures provide diverse and suitable environments for various species to thrive. Berms, for example, can act as protective barriers and create microclimates that support the growth of vegetation preferred by certain wildlife. Ponds and wetlands offer water sources and breeding grounds for amphibians, birds, and other aquatic species. By altering the landscape and incorporating earthwork products, we can create habitats that attract and sustain a wide range of wildlife, ultimately promoting biodiversity and ecological balance.

- Q: How are gabion baskets filled and installed?

- Gabion baskets are filled by placing rocks or other suitable materials into the wire mesh cages. The rocks are typically sized to fit within the gaps of the wire mesh, ensuring a stable and compact filling. Once the baskets are filled, they are securely closed and tied to maintain their shape. Installation involves placing the filled gabion baskets in the desired location, usually on a prepared foundation, and connecting them to form a continuous structure. This can be done by wire or metal clips, ensuring the baskets are securely interconnected.

- Q: Can earthwork products be used for soundproofing applications?

- Yes, earthwork products can be used for soundproofing applications. The dense and solid nature of earthwork materials, such as clay or compacted soil, can effectively absorb and block sound waves, reducing noise transmission. Additionally, using earthwork products as building materials can create a thermal mass that further enhances soundproofing capabilities.

- Q: What are the different installation guidelines for earthwork products?

- The specific installation guidelines for earthwork products can vary depending on the type of product being used. However, some general guidelines include properly preparing the site by removing any vegetation or debris, ensuring proper drainage to prevent water accumulation, compacting the soil or base material to create a stable foundation, and carefully following the manufacturer's instructions for product installation. It is also important to consider factors such as slope stability, soil conditions, and local regulations when installing earthwork products.

- Q: Can earthwork products be used for constructing stormwater detention ponds?

- Yes, earthwork products can be used for constructing stormwater detention ponds. These products, such as soil, clay, and gravel, can be used to shape the pond's basin, create berms or embankments, and provide stability to the structure. The earthwork materials play a crucial role in managing and containing stormwater runoff, preventing flooding, and improving water quality.

- Q: How are geosynthetic materials tested for quality and performance?

- Geosynthetic materials are tested for quality and performance through a combination of physical, mechanical, and chemical tests. These tests may include tensile strength, tear resistance, puncture resistance, seam strength, UV stability, chemical resistance, and durability testing. Additionally, geosynthetic materials are often subjected to simulated environmental conditions such as extreme temperatures, moisture, and aging to assess their long-term performance. These rigorous testing processes ensure that geosynthetic materials meet the required standards and can perform effectively in various geotechnical applications.

- Q: How do geosynthetic panels help in land reclamation projects?

- Geosynthetic panels are beneficial in land reclamation projects as they provide erosion control, stabilize soil, and aid in the establishment of vegetation. These panels act as a barrier, preventing soil erosion caused by wind and water, while also promoting the growth of plants by improving soil fertility and moisture retention. Additionally, they help in reinforcing slopes and retaining walls, ensuring the stability of the reclaimed land.

- Q: Are earthwork products resistant to weathering and deterioration?

- Yes, earthwork products are generally resistant to weathering and deterioration due to their natural composition and ability to withstand environmental factors such as rain, wind, and temperature fluctuations.

Send your message to us

Geosynthetic Clay Liner(GCL) for Anti-seepage

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords