Geocomposite Geosynthetic Clay Liner/GCL for Lanfill Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

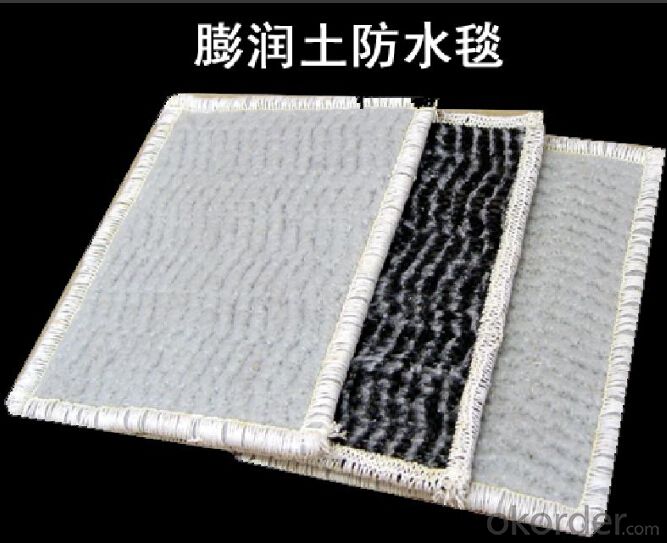

GCL(Geocomposite Geosynthetic Clay Liner)

Description :

Geosynthetic clay liners (GCLs) are high performance needle punched environmental reinforced composites which combine two durable geotextile outer layers with a uniform core of natural sodium bentonite clay to form a hydraulic barrier. Fibers from the non-woven geotextile are needle punched through the layer of bentonite and incorporated into the other geotextile (either a woven or non-woven).when hydrated under a confining load, the bentonite swells to form a low permeability clay layer with the equivalent hydraulic protection of several feet of compacted clay.

Specification:

Geonet thickness: 5-8mm; Width: 2-4m; Length as requested

Geotextile can be needle punched polyester geotextile, continuous filament PET nonwoven geotextile or Polypropylene nonwoven geotextile, and the unit weight normally 200g/m2.

Features:

1. Excellent drainage function, able to bear long time high pressure load

2. High tensile and shear strength

3. Able to protect its long time and stable hydraulic conductivity

4. Able to bear more than 2000kpa compression load, its anti-pressure capacity much higher than common drainage network

5. Corrosion resistant, acid and alkali resistant.

Applications:

Seepage proofing, anticorrosion, leaking stoppage and reinforcement

1. Municipal engineering, underground construction of subway, buildings as well as the roof tank.

2. Environmental sanitation, solid waste landfill, sewage farm, industrial waste

3. water conservancy, lake, river, dam and reservoir.

4. Garden and park, artificial lake and golf cause pool.

5. Petrochemical engineering, mining industry and agriculture engineering

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

GCL Technical Index

Item | Specification | ||||

GCL-NP | GCL-OF | GCL-AH | |||

Mass per unit g/m2 | ≥ 4000 (not less than the specified value) | ≥ 4000 (not less than the specified value) | ≥ 4000 (not less than the specified value) | ||

GCL expansion index ml/2g | ≥24 | ≥24 | ≥24 | ||

Blue absorption power g/100g | ≥ 30 | ≥ 30 | ≥ 30 | ||

Tensile Strength N/ 100mm | ≥ 600 | ≥ 700 | ≥ 600 | ||

Elongation at maximum load % | ≥ 10 | ≥ 10 | ≥ 8 | ||

Peel strength N / 100mm | Nonwoven geotextile and woven geotextile | ≥ 40 | ≥ 40 | - | |

PE geommebrane and nonwoven geotextile | - | ≥ 30 | - | ||

Permeability coefficient m/s | ≤ 5.0x10-11 | ≤ 5.0x10-12 | ≤ 1.0x10-12 | ||

Hydrostatic pressure resistant | 0.4 Mpa , 1h, no leakage | 0.6 Mpa ,1h,no leakage | 0.6Mpa ,1h, no leakage | ||

Filter loss ml | ≤ 18 | ≤ 18 | ≤ 18 | ||

Durability of bentonite ml/ 2g | ≥ 20 | ≥ 20 | |||

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: What are the key considerations when using geosynthetic materials in bridge construction?

- Some key considerations when using geosynthetic materials in bridge construction include selecting the appropriate type of geosynthetic material based on the specific project requirements, considering the durability and longevity of the material, ensuring proper installation and construction techniques, evaluating the material's ability to withstand environmental factors such as temperature changes and moisture, and conducting regular inspections and maintenance to ensure the material's performance over time. Additionally, it is important to consider the cost-effectiveness of using geosynthetics compared to traditional construction materials and methods.

- Q: Can earthwork products be used for channel lining?

- Yes, earthwork products can be used for channel lining.

- Q: Are earthwork products suitable for use in mining applications?

- Yes, earthwork products are suitable for use in mining applications. These products, such as geotextiles, geomembranes, and geosynthetics, provide effective solutions for erosion control, slope stabilization, and environmental protection in mining operations. They are designed to withstand the harsh conditions and heavy loads associated with mining activities, making them highly suitable for use in such applications.

- Q: What are the different jointing options available for earthwork products?

- Some of the different jointing options available for earthwork products include mechanical joints, such as dowel bars or tie bars, which provide structural integrity and resist movement between adjacent elements. Another option is using flexible materials like geotextiles or geogrids to create a reinforced joint, allowing for some movement while still maintaining stability. Additionally, adhesive or sealant joints can be used to create a watertight barrier between earthwork products, preventing water infiltration and potential damage.

- Q: What are the fire safety properties of earthwork products?

- Earthwork products, such as soil and clay, do not possess inherent fire safety properties. In fact, these materials can be highly combustible and may contribute to the spread and intensity of fires. Adequate fire prevention measures, such as maintaining clearances, implementing fire breaks, and employing fire-resistant coatings, are necessary to mitigate the fire risks associated with earthwork products.

- Q: Can earthwork products be used in underground utility installations?

- Yes, earthwork products can be used in underground utility installations. Earthwork products such as geotextiles, geogrids, and geomembranes are commonly used to enhance the stability, strength, and longevity of underground utility installations. These products help in preventing soil erosion, providing reinforcement to the soil structure, and improving overall performance and durability of underground utilities.

- Q: On the Title of Civil Engineering

- I am learning materials (material molding), but I now work in the construction unit, or civil engineering is good, (their own feelings) good job opportunities, work is also good treatment.

- Q: How do earthwork products help with noise reduction?

- Earthwork products help with noise reduction by acting as barriers or sound absorbers. For example, using earthen berms or mounds as a natural sound barrier can help to block or deflect noise, minimizing its impact on surrounding areas. Additionally, materials like soil, gravel, or vegetation can absorb sound waves, reducing their intensity and creating a quieter environment.

- Q: How are geocomposites used in earthwork?

- Geocomposites are used in earthwork to provide reinforcement, filtration, and separation functionalities. They are commonly used in applications such as road construction, retaining walls, and landfill systems. The composite structure combines different materials like geotextiles, geogrids, and geomembranes, allowing for improved drainage, soil stabilization, and prevention of soil erosion. Overall, geocomposites enhance the performance and longevity of earthwork projects.

- Q: What are the advantages of using geosynthetic erosion control blankets?

- Geosynthetic erosion control blankets offer several advantages, including providing immediate erosion protection, reducing sediment runoff, promoting vegetation growth, enhancing slope stability, and being cost-effective and easy to install.

Send your message to us

Geocomposite Geosynthetic Clay Liner/GCL for Lanfill Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords