Bentonite Geosynthetic Clay Liner (GCL) /Lake Hydraulic Barriers

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

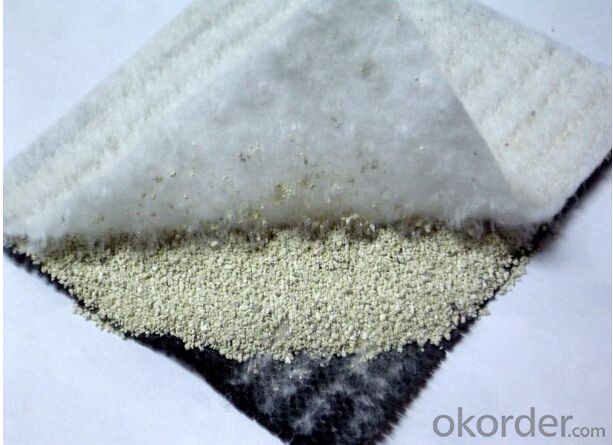

Bentonite Geosynthetic Clay Liner (GCL)

Introduction:

Mass per unit ≥ 4000g / m²

Width: 4-6 m

size: 5.8 x 30m , or customized

bentonite sandwiched between two layers of geotextile

Features:

1) compacted with clay liner, it has the advantages of

small size, light weight, good flexibility and compactibility

2) easy for construction and suitable for uneven settlement.

3) not affected by temperature

4) permanent waterproofness

5) eco-friendly

Applications:

Landfill sealing

Liquid containment

Secondary containment

Mining

GCL Technical Index

Item | Specification | ||||

GCL-NP | GCL-OF | GCL-AH | |||

Mass per unit g/m2 | ≥ 4000 (not less than the specified value) | ≥ 4000 (not less than the specified value) | ≥ 4000 (not less than the specified value) | ||

GCL expansion index ml/2g | ≥24 | ≥24 | ≥24 | ||

Blue absorption power g/100g | ≥ 30 | ≥ 30 | ≥ 30 | ||

Tensile Strength N/ 100mm | ≥ 600 | ≥ 700 | ≥ 600 | ||

Elongation at maximum load % | ≥ 10 | ≥ 10 | ≥ 8 | ||

Peel strength N / 100mm | Nonwoven geotextile and woven geotextile | ≥ 40 | ≥ 40 | - | |

PE geommebrane and nonwoven geotextile | - | ≥ 30 | - | ||

Permeability coefficient m/s | ≤ 5.0x10-11 | ≤ 5.0x10-12 | ≤ 1.0x10-12 | ||

Hydrostatic pressure resistant | 0.4 Mpa , 1h, no leakage | 0.6 Mpa ,1h,no leakage | 0.6Mpa ,1h, no leakage | ||

Filter loss ml | ≤ 18 | ≤ 18 | ≤ 18 | ||

Durability of bentonite ml/ 2g | ≥ 20 | ≥ 20 | |||

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: Are earthwork products suitable for bridge approach embankments?

- Yes, earthwork products are suitable for bridge approach embankments. Earthwork products such as fill materials, compacted soil, and geosynthetic materials can be used to construct stable and sturdy embankments for bridge approaches. These materials provide strength, stability, and erosion control, making them an ideal choice for creating safe and reliable bridge approach embankments.

- Q: How are geogrids used for soil stabilization in embankment construction?

- Geogrids are used for soil stabilization in embankment construction by reinforcing and strengthening the soil structure. They are typically placed within the soil layers to provide additional tensile strength, preventing soil erosion and slope failure. The geogrids act as a barrier to lateral movement, distributing loads more evenly and increasing the overall stability of the embankment.

- Q: Do earthwork products require any special maintenance?

- Yes, earthwork products such as retaining walls or berms may require regular maintenance to ensure their stability and effectiveness. This can include inspecting for any signs of erosion, settling, or damage, and addressing them promptly. Additionally, vegetation control and regular cleaning may be necessary to prevent blockages or obstructions. Overall, proper maintenance is crucial to extend the lifespan and functionality of earthwork products.

- Q: Are geosynthetics resistant to chemical degradation?

- Yes, geosynthetics are generally resistant to chemical degradation. They are designed to withstand exposure to various chemicals and have been tested to ensure their resistance to degradation over time. However, the specific level of resistance can vary depending on the type of geosynthetic material and the specific chemicals involved.

- Q: How do earthwork products help with stormwater management?

- Earthwork products such as permeable pavers, retention basins, and bioswales help with stormwater management by facilitating the infiltration and storage of rainwater. These products allow rainwater to seep into the ground, replenish groundwater supplies, and reduce stormwater runoff, which helps prevent flooding, erosion, and pollution of water bodies.

- Q: What are the different types of erosion control mats?

- There are several types of erosion control mats, including straw or hay mats, coconut fiber mats, jute mats, and synthetic erosion control mats made from materials such as polypropylene.

- Q: How do earthwork products contribute to vegetation establishment?

- Earthwork products, such as topsoil, mulch, and compost, play a crucial role in vegetation establishment. These products provide a fertile and nutrient-rich substrate for plant growth, promoting healthy root development and ensuring successful establishment. They also help retain moisture in the soil, reducing water stress on newly planted vegetation. By improving soil quality and creating favorable conditions, earthwork products greatly enhance the chances of successful vegetation establishment.

- Q: What are the benefits of using geosynthetic reinforcement for soil stabilization?

- Geosynthetic reinforcement offers several benefits for soil stabilization. Firstly, it enhances the overall strength and stability of the soil, making it suitable for a variety of construction applications. Additionally, geosynthetics help in reducing soil erosion and preventing slope failures, thus ensuring long-term durability. They also improve the load-bearing capacity of the soil, allowing for the construction of structures on weaker or problematic soils. Furthermore, using geosynthetic reinforcement reduces the need for excessive excavation and costly soil replacement, resulting in significant cost savings. Overall, geosynthetic reinforcement is a reliable and efficient solution for achieving soil stability and preventing soil-related issues.

- Q: What are the benefits of using geomembranes for pond liners?

- Geomembranes offer several benefits for pond liners. Firstly, they provide a highly reliable barrier against water seepage, preventing leakage and ensuring the integrity of the pond. This helps to conserve water and maintain the desired water level. Secondly, geomembranes are durable and resistant to UV radiation, chemicals, and punctures, increasing the lifespan of the pond liner. Additionally, they are flexible and can be custom-fabricated to fit any pond size or shape, allowing for greater design flexibility. Moreover, geomembranes are relatively easy to install and require minimal maintenance, reducing overall costs and effort. Lastly, they are environmentally friendly as they prevent contamination of groundwater and soil by preventing the migration of pollutants from the pond.

- Q: How do earthwork products help with slope stabilization?

- Earthwork products, such as geogrids and geotextiles, play a crucial role in slope stabilization. These products are designed to reinforce the soil and provide structural support to slopes, preventing erosion and landslides. They help distribute the weight of the soil and reduce the pressure on the slope, increasing its stability. Additionally, these products can improve the drainage and filtration properties of the soil, which further enhances slope stability by reducing water accumulation and preventing soil saturation.

Send your message to us

Bentonite Geosynthetic Clay Liner (GCL) /Lake Hydraulic Barriers

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords