PP Fiber Mesh for Concrete Use with Certification

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

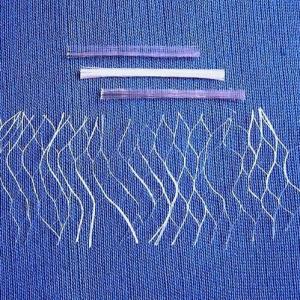

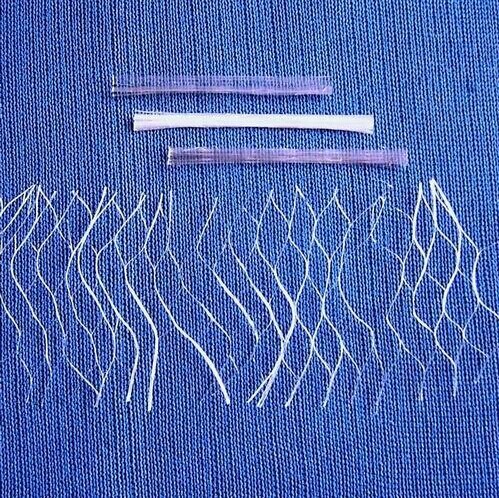

1. Specification of PP Fiber Mesh for Concrete Use

Density(g/cm 3 ) | 0.91 | Elastic Modulas (MPa) | >3500 |

Length(mm) | 6,10,12,15,20 | Equivalent Diameter m) | 100 |

Shape | Beam-like Net | Crack Elongation(%) | ≥10 |

Acid &Alkali Resistance | Strong | Water-Absorbency | No |

Tensile Strength(MPa) | 346-560 | Melting Point(°C) | 160—170 |

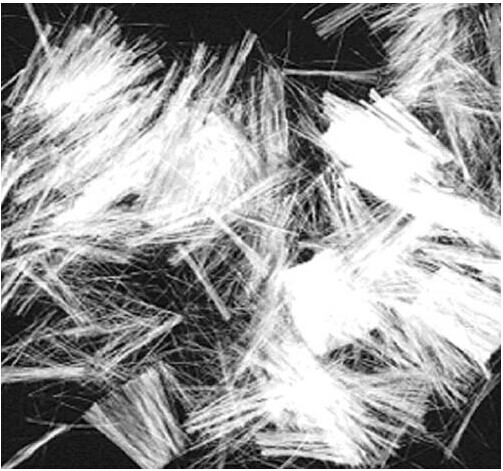

2. Product Features of PP Fiber Mesh for Concrete Use

Prolong endurance

Improve steel protection

Increase cracking resistance

Increase fire resistance

Strengthen spurt & fatigue

Strong acid & alkali resistance and good endurance

Improve plastic deformity

Improve tensile, bending & folding strength

Increase seepage resistance

3. Product Package of PP Fiber Mesh for Concrete Use

Inner: 0.9kg/bag

Outer: 12.6kg/box

4. Application of PP Fiber Mesh for Concrete Use

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

- Q: What are the different types of geotextile fabric installation methods?

- There are several types of geotextile fabric installation methods, including trenching, overlaying, and wrapping. Trenching involves digging a trench and placing the fabric at the desired depth before backfilling. Overlaying involves placing the fabric over a prepared surface and then covering it with another layer of material. Wrapping involves encasing a structure or object with the fabric to provide protection and stability. These installation methods are used to enhance soil stabilization, erosion control, and drainage in various civil engineering and construction projects.

- Q: How are geosynthetic materials used in retaining wall reinforcement?

- Geosynthetic materials are commonly used in retaining wall reinforcement to enhance stability and prevent soil erosion. These materials, such as geotextiles and geogrids, are placed within different layers of the retaining wall structure to provide additional support and improve the overall strength of the wall. They act as a barrier to separate and distribute the forces exerted by the soil, reducing the risk of wall failure and promoting long-term durability.

- Q: Can earthwork products be used for bridge construction?

- Yes, earthwork products can be used for bridge construction. Earthworks involve the manipulation of soil and other natural materials, and these materials can be utilized for various aspects of bridge construction, such as embankments, approaches, and abutments.

- Q: What are the key considerations when using geosynthetic materials in bridge construction?

- When using geosynthetic materials in bridge construction, some key considerations include the selection of the appropriate type of geosynthetic material based on the project requirements, understanding the load-bearing capacity and durability of the material, ensuring proper installation techniques are followed, and conducting regular inspections and maintenance to ensure the long-term performance of the geosynthetic materials. Additionally, it is important to consider the potential environmental impacts and compatibility of the geosynthetic materials with other components of the bridge structure.

- Q: What are the long-term performance benefits of earthwork products?

- The long-term performance benefits of earthwork products include improved stability and strength of the soil, erosion control, enhanced drainage, and increased durability. These products provide long-lasting solutions that help to maintain the integrity of the earthwork projects over time.

- Q: Can geomembranes be used for floating covers in reservoirs?

- Yes, geomembranes can be used for floating covers in reservoirs. Their impermeable nature and resistance to UV rays make them an effective choice for preventing evaporation and contamination of the water in the reservoir. Additionally, the flexibility of geomembranes allows them to conform to the shape of the reservoir and provide a secure cover.

- Q: How do geosynthetic liners prevent seepage in stormwater detention ponds?

- Geosynthetic liners prevent seepage in stormwater detention ponds by providing a barrier that prevents water from infiltrating the soil beneath the pond. These liners are made of synthetic materials such as polyethylene or polypropylene, which are impermeable to water. When installed properly, they create a reliable barrier that prevents the loss of water from the pond and helps maintain the desired water level. Additionally, geosynthetic liners can also prevent the migration of pollutants from the pond into the surrounding soil and groundwater, ensuring environmental protection.

- Q: Are earthwork products suitable for use in coastal areas?

- Yes, earthwork products can be suitable for use in coastal areas. These products, such as geotextiles and erosion control materials, can help stabilize the soil, prevent erosion and protect coastal areas from the impact of waves, tides, and storms. They can be used to reinforce dunes, construct seawalls, or create barriers that prevent sediment migration. However, the specific suitability of earthwork products may depend on factors like the local climate, wave conditions, and the type of coastal environment.

- Q: What are the different types of geosynthetic drainage materials?

- The different types of geosynthetic drainage materials include geotextiles, geonets, geocomposites, geospacers, and geocomposite drains.

- Q: What are the advantages of using geocells for load support in pavements?

- There are several advantages of using geocells for load support in pavements. Firstly, geocells provide increased structural stability and load-bearing capacity to the pavement, making it more durable and capable of withstanding heavy traffic loads. Secondly, geocells distribute the load more evenly across the pavement surface, reducing localized stresses and preventing rutting and deformation. Additionally, geocells can be easily installed and require minimal maintenance, reducing construction and maintenance costs. Moreover, geocells enhance the overall performance of the pavement by improving drainage and preventing the loss of base materials, thereby increasing the lifespan of the pavement.

Send your message to us

PP Fiber Mesh for Concrete Use with Certification

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 300000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches