Monofilament PP Fiber for Concrete Usage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Main Introduction of Monofilament PP Fiber for Concrete

PP fiber is also called engineering fiber,concrete fiber,anti-crack fiber,crack control fiber,synthetic fiber or plastic fiber,etc.It is a kind of high intensity bunchy monofilament fiber mainly made of PP by special technique

Put PP fiber into the concrete or mortar, can effectively prevent temperature change, microcrack caused by plastic and dry shrinkage,etc, thereby prevent crack and improve effectively anti-crack,anti-infiltration,anti-concussion and anti- shock of the concrete.

They are used in roads,bridges,underground waterproof projects and roofings,walls,pools,basements of the industrial civil construction

2. Specifications of Monofilament PP Fiber for Concrete

PARAMETER | UNIT | GUARANTEE VALUE |

Specific Gravity | g/cm3 | 0.91~0.93 |

Available lengths | mm | 3, 6, 10, 12, 15, 19 |

Tensile Strength | Mpa | 450 min |

Modulus of Elasticity | Mpa | 3000 min |

Melt Point | °C | 160~180 |

Heat Conductivity | - | LOW |

Water Absorption | - | NEGLIGIBLE |

3. Product Function of Monofilament PP Fiber for Concrete

1). Resist to shrink & crack;

2). Increase impact resistance and peeling resistance;

3). Increase friction resistance;

4). Increase seepage resistance;

5). Increase freezing & thawing resistance;

6). Improve tendons protection

7). Prevent mortar split and crackle expansion;

8). Replace steel net (using in plastering).

4.FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

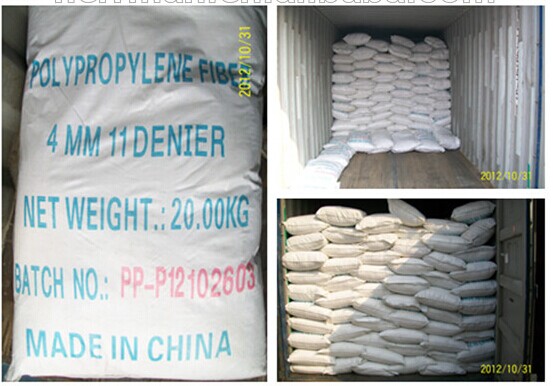

5. Product Show of Monofilament PP Fiber for Concrete

- Q: How do geocomposites help in erosion control in earthwork applications?

- Geocomposites help in erosion control in earthwork applications by providing an effective barrier against soil erosion. They are made up of multiple layers, typically consisting of a geotextile and a geomembrane, which work together to prevent the movement of soil particles and the loss of vegetation. The geotextile layer acts as a filter, allowing water to pass through while retaining soil particles, and the geomembrane layer acts as a barrier, preventing water from infiltrating the soil and causing erosion. This combination of layers helps to stabilize slopes, control runoff, and protect the underlying soil, ultimately reducing erosion and improving the overall durability of earthwork structures.

- Q: What is the purpose of using geotextile tubes in shoreline stabilization projects?

- The purpose of using geotextile tubes in shoreline stabilization projects is to provide effective erosion control and protect coastal areas from the damaging effects of waves, currents, and storms. These tubes act as a barrier, trapping sediment and preventing it from being washed away, while also promoting the growth of vegetation. They offer a cost-effective and environmentally friendly solution to maintain and restore the natural balance of coastal ecosystems.

- Q: What are the common applications of earthwork products in landscaping?

- Earthwork products are commonly used in landscaping for a variety of applications. These include creating raised beds for gardens, building retaining walls to prevent soil erosion, shaping slopes and embankments for aesthetic purposes, and leveling the ground for installing pathways or driveways. Additionally, earthwork products can be used to create terraces, construct ponds or water features, and even sculpt the landscape to create unique and visually appealing designs.

- Q: How are geosynthetic clay liners used in earthwork?

- Geosynthetic clay liners are used in earthwork as a barrier to prevent the migration of liquids or gases within soil or rock structures. These liners are typically installed in landfills, dams, and other construction projects to enhance the containment and stability of the earthwork. They offer excellent hydraulic conductivity and chemical resistance, providing an effective solution for environmental protection and geotechnical engineering.

- Q: Can geomembranes be used for secondary containment?

- Yes, geomembranes can be used for secondary containment. They are impermeable barriers that can effectively contain and prevent the escape of liquids or hazardous materials. Geomembranes are commonly used in various industries, such as oil and gas, chemical, and waste management, to provide an additional layer of protection against potential leaks or spills.

- Q: Will the mechanical material mechanics and civil material mechanics different?

- There is a difference is yes. Mechanical material mechanical content is mainly mechanical transmission shaft of a class, civil material mechanics is mainly bar and beam, truss, steel frame, arch structure of the force analysis.

- Q: How do earthwork products contribute to water filtration?

- Earthwork products, such as clay, sand, and gravel, play a crucial role in water filtration. These materials are used in various filtration systems, such as bioswales, rain gardens, and infiltration trenches. When water passes through these earthwork products, they act as natural filters, removing impurities, sediments, and pollutants. Additionally, the porous nature of these materials allows water to slowly infiltrate the ground, promoting groundwater recharge and reducing stormwater runoff. Overall, earthwork products facilitate the purification of water by enhancing its quality and promoting sustainable water management practices.

- Q: How are geosynthetic materials used in coastal protection structures?

- Geosynthetic materials are commonly used in coastal protection structures for various purposes. They are employed to stabilize shorelines, control erosion, and provide structural support to prevent coastal land loss. Geotextiles, for instance, are often used as an underlay for coastal revetments or seawalls, enhancing their stability and preventing soil erosion. Additionally, geotubes, which are large geosynthetic containers filled with sand, can be deployed as breakwaters or dune reinforcements, effectively absorbing wave energy and protecting vulnerable coastal areas. Overall, geosynthetic materials play a crucial role in coastal protection by providing cost-effective and sustainable solutions for shoreline stabilization and erosion control.

- Q: What are the advantages of using earthwork products in land reclamation?

- There are several advantages of using earthwork products in land reclamation. Firstly, earthwork products such as soil, gravel, and stones can provide a stable foundation for building structures and infrastructure on reclaimed land. These materials help to prevent erosion, stabilize slopes, and improve the overall stability of the land. Secondly, earthwork products can be used to reshape the topography of reclaimed land, creating desired contours, leveling uneven surfaces, and forming drainage channels. This allows for better land utilization, as the land can be made suitable for various purposes such as agriculture, residential or commercial development, or recreational activities. Additionally, earthwork products can enhance the fertility and productivity of reclaimed land by adding organic matter, nutrients, and beneficial microorganisms to the soil. This can lead to improved agricultural yields and the establishment of green spaces or parks. Moreover, using earthwork products in land reclamation can be a cost-effective solution compared to importing soil or other materials from other locations. It reduces the need for transportation, saves time, and minimizes the environmental impact associated with long-distance hauling. Overall, the advantages of using earthwork products in land reclamation include increased land stability, improved topography, enhanced fertility, cost-effectiveness, and reduced environmental impact.

- Q: The Importance of Civil Engineering Materials in Engineering Construction

- Different types of materials, mechanical coefficient, the construction method will be different, the impact of the construction process, the impact of the demand for materials, the impact on the cost of the project impact, the impact on the quality of the project.

Send your message to us

Monofilament PP Fiber for Concrete Usage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords