Polypropylene Mesh Fiber for Concrete Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction of Polypropylene Mesh Fiber for Concrete Use

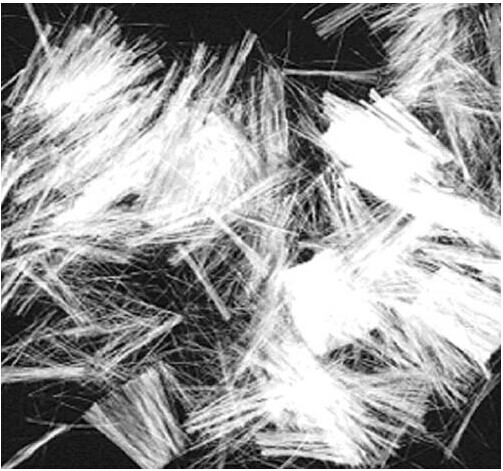

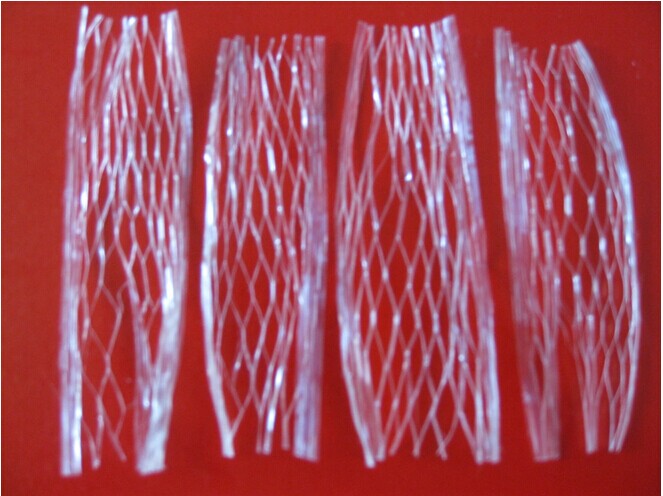

Polypropylene mesh fiber, also called mesh type polypropylene fiber and PP fibermesh. With polypropylene as its raw material, PP fiber mesh is produced by a specialtechnology. It looks like a net-like structure with many PP monofilament. cross linked with each other.

As a new type of concrete reinforcement fiber, it is a new hot spot in application field of concrete fiber after steel fiber, polypropylene monofilament fiber.

2. Product Specification of Polypropylene Mesh Fiber for Concrete Use

Raw material | polypropylene |

Type | Mesh |

Fiber dia | 0.1mm |

Length | 15,19, 38mm |

Crack Elongation | ≥15% |

Density | 0.91g/cm³ |

Melting point | 160-170°C |

Tensile Strength | ≥550Mpa |

Elastic Modulus | >3300Mpa |

Resistance to Acid, Alkali | Strong |

Water Absorbency | No |

3. Product Features of Polypropylene Mesh Fiber for Concrete Use

Polypropylene fiber mesh, as the filling material of concrete, has the properties of good dispersibility, resistance to acid and alkali. The main functions are:

1). Increase the crack resistance of concrete;

2). Increase the seepage retansisce of concrete;

3). Increase the freezing & thawing resistance of concrete;

4). Increase the impact resistance of concrete;

5). Increase the durability resistance of concrete;

6). Increase the fire resistance of concrete;

7). Increase the tensile strength and bending strength of concrete;

8). Increase the plastic deformation ability of concrete.

4. Application of Polypropylene Mesh Fiber for Concrete Use

1). The surface of road, bridge, runway and floor of the factory.

2). Wall and roof of the tunnel and mine.

3). Dam, river, bridge pier, dock and military protection facilities.

5.FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

6. Product Photos of Polypropylene Mesh Fiber for Concrete Use

- Q: Can earthwork products be used in both residential and commercial construction?

- Yes, earthwork products can be used in both residential and commercial construction. Earthwork products such as soil, gravel, and rocks, are commonly used in various construction projects including building foundations, landscaping, road construction, and drainage systems, irrespective of whether it is for residential or commercial purposes.

- Q: Can geosynthetics be used for lining fish ponds?

- Yes, geosynthetics can be used for lining fish ponds. They are commonly used as liners in various environmental and agricultural applications, including fish ponds. Geosynthetics provide an effective barrier to prevent seepage and leakage, maintaining water levels and quality in the pond. They are durable, flexible, and resistant to degradation, making them suitable for long-term use in fish pond lining.

- Q: How are geotextile mats used in sediment control during river dredging?

- Geotextile mats are used in sediment control during river dredging by being placed on the riverbed to prevent the stirred-up sediments from spreading downstream. These mats act as a barrier, trapping the sediments while allowing water to pass through. This helps to minimize the environmental impact of dredging activities by reducing sedimentation in downstream areas and protecting water quality.

- Q: What are the specific applications of geotextile containers in earthwork projects?

- Geotextile containers, also known as geotextile bags or geobags, find specific applications in earthwork projects such as shoreline protection, sediment control, and erosion control. These containers are filled with soil, sand, or other granular materials to create structures like retaining walls, revetments, and dikes. They provide stability and prevent erosion by trapping sediment, reducing water flow velocity, and promoting vegetation growth. Geotextile containers are also used in land reclamation, dredging, and construction projects where the need for temporary or permanent containment of materials is crucial.

- Q: How do earthwork products compare to traditional construction materials in terms of cost?

- Earthwork products, such as soil, gravel, and rocks, tend to be more cost-effective compared to traditional construction materials. This is primarily because earthwork materials are often readily available on-site or can be easily sourced locally, reducing transportation costs. Additionally, earthwork products can be recycled or reused, further minimizing expenses. On the other hand, traditional construction materials like concrete, steel, and lumber typically require more resources, energy, and manufacturing processes, making them relatively more expensive. However, it is important to note that the specific cost comparison may vary depending on factors such as project location, scale, and availability of materials.

- Q: Help students learn sister, civil engineering materials

- Concrete: ordinary concrete, high strength and high performance concrete, fly ash concrete, light concrete, special concrete

- Q: How can geocomposites be used in subsurface irrigation systems?

- Geocomposites can be used in subsurface irrigation systems by acting as a barrier to control water flow, preventing soil erosion and enhancing water distribution to plant roots. They help to evenly distribute water throughout the irrigation area, reducing water waste and increasing efficiency. Additionally, geocomposites can improve the overall performance and longevity of the irrigation system by providing stability and protection against clogging and root intrusion.

- Q: Can earthwork products be used in agricultural applications?

- Yes, earthwork products can be used in agricultural applications. They can be used for various purposes such as land leveling, soil stabilization, erosion control, and drainage management. For example, products like geotextiles, geomembranes, and geocells can be used to reinforce soil, prevent erosion, and improve water containment in agricultural fields. Additionally, earthwork machinery such as excavators and bulldozers can be used for activities like land clearing and terracing, which are essential in agricultural practices.

- Q: Are there any earthwork products specifically designed for airport construction?

- Yes, there are several earthwork products specifically designed for airport construction. These include materials such as geotextiles, geogrids, and erosion control products that are used to stabilize the soil, reinforce embankments, and prevent erosion on airport construction sites. Additionally, specialized soil additives and stabilizers are used to enhance the strength and stability of the soil, ensuring the longevity and safety of airport infrastructure.

- Q: What are the different types of retaining walls?

- Some of the different types of retaining walls include gravity walls, cantilever walls, sheet pile walls, anchored walls, and gabion walls.

Send your message to us

Polypropylene Mesh Fiber for Concrete Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords