Polypropylene Fiber 12mm for Concrete Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Polypropylene fiber Introduction

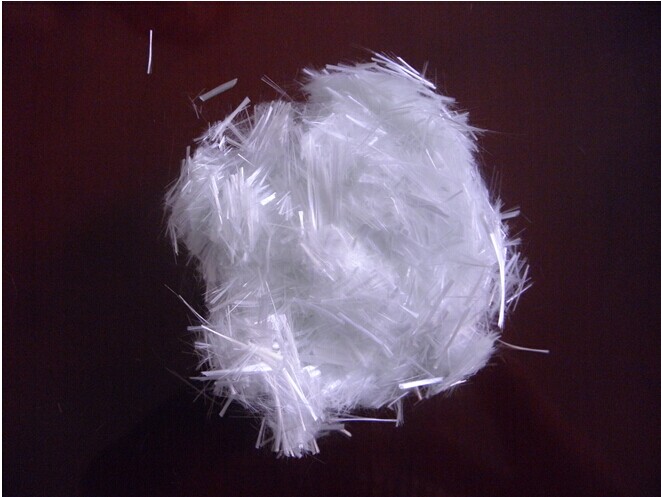

With polypropylene as its raw material, this fiber is produced by special technology,

the products have net-like structure with many fiber monofilaments.

When the fiber is put into the concrete,

the horizontal structure in fiber monofilament can be destroyed in the course of stirring owing

to friction and rubbing, and the fiber monofilament or net like structure will fully stretch,

thus the concrete is reinforced by a great number of polypropylene fibers.

2. Characteristics of Polypropylene fiber 12mm

Appearance | Bunchy monofilametn | Elastic Modulas(MPa) | >3500 |

Density(g/cm³) | 0.91±0.01 | Crack Elongation(%) | >10 |

Shape | Net-like structure or monofilametns | Water-Absorbency | No |

Acid&Alkali Resistance | Strong | Melting Point(°C) | 160-180 |

Tensile Strength(MPa) | ≥560 | Hot conduction | low |

Electrical Conduction | low | Thickness | 25-35um |

3. Application of PP Fiber for Concrete Reinforcement

1)Industrial projects,such as the floor, inner & outer wall;underground waterproof layer,

natatorium/swimming pool, pond and dam, workshop,warehouse and parking lot;

2)Common concrete projects,such as highway, railway,bridge and others;

3)Used as refractory material;

4)Basement of the civil construction

4. PP Fiber advantages:

1.Prevention of the mortar’s contraction crack.

2.Improvement of the wall’s anti-shock and resistance to stripping.

3.Increasing of anti-permeability of wall.

4.Strengthen resistance to freezing and thawing.

5.Improve the ability of protection of reinforcement.

6.Prevent mud crack and crack propagation of mortar.

7.Substitute for steel mesh.

5. FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

6. Product Photos of PP Fiber for Concrete Reinforcement

- Q: Can earthwork products be used in road embankment construction?

- Yes, earthwork products can be used in road embankment construction. Earthwork products, such as soil, gravel, and other materials, are commonly used to build up road embankments. These materials are compacted and layered to create a stable foundation and to ensure proper drainage.

- Q: What are the classification of civil engineering graduate students?

- Major professional basic courses and specialized courses / structural engineering, engineering mechanics and water conservancy projects

- Q: How do earthwork products help with erosion control?

- Earthwork products help with erosion control by providing a physical barrier that prevents soil erosion. These products, such as geotextiles and erosion control blankets, stabilize the soil surface, reduce the impact of rainfall, and promote vegetation growth, thereby preventing the loss of topsoil and protecting slopes from erosion.

- Q: Can earthwork products be used in bridge construction?

- Yes, earthwork products can be used in bridge construction. Earthwork products such as soil, rocks, and geotextiles are commonly used for various aspects of bridge construction including foundation preparation, slope stabilization, and erosion control.

- Q: How do geosynthetic products contribute to soil erosion prevention in orchards?

- Geosynthetic products, such as geotextiles and geogrids, play a crucial role in preventing soil erosion in orchards. These materials are used as erosion control measures by stabilizing the soil and preventing it from being washed away by water or wind. Geotextiles act as a barrier that retains soil particles while allowing water to pass through, reducing the impact of raindrop impact and surface runoff. Geogrids provide reinforcement to the soil, increasing its shear resistance and preventing slope failure. By effectively controlling erosion, geosynthetic products help maintain the integrity of orchard soils, protecting their fertility and ensuring sustainable orchard management.

- Q: How do geosynthetic clay liners prevent seepage in pond liners?

- Geosynthetic clay liners (GCLs) prevent seepage in pond liners by combining the properties of geotextiles and clay. These liners are composed of a layer of bentonite clay sandwiched between two layers of geotextiles. The clay in GCLs has a high swelling capacity, which allows it to absorb water and form a barrier against seepage. When water comes into contact with the GCL, the clay swells, creating a dense, impermeable layer that prevents water from passing through. Additionally, the geotextiles act as reinforcement, providing strength and stability to the GCL. This combination of clay and geotextiles makes GCLs an effective solution for preventing seepage in pond liners.

- Q: How do earthwork products contribute to soil moisture retention?

- Earthwork products, such as contour ploughing, terracing, and mulching, play a crucial role in retaining soil moisture. Contour ploughing helps to slow down water runoff and allows water to infiltrate the soil, thus increasing soil moisture levels. Terracing prevents soil erosion by creating flat areas on slopes, which helps retain water in the soil. Mulching, on the other hand, acts as a protective layer over the soil, reducing evaporation and allowing the soil to retain moisture for longer periods. Overall, these earthwork techniques contribute to improved soil moisture retention, which is essential for plant growth and ecosystem health.

- Q: Civil engineering materials stone test, the determination of stone grade with what practical significance?

- And grading does not meet the requirements, that is, grading grading grading can not wrap cement mortar, prone to segregation. You gravel grading is to see if it can meet these requirements

- Q: What is the purpose of using geocomposites in landfill leachate collection systems?

- The purpose of using geocomposites in landfill leachate collection systems is to enhance the efficiency and effectiveness of leachate collection. Geocomposites are engineered materials that combine different geosynthetic components, such as geotextiles and geonets, to create a high-performance system. These materials provide multiple benefits in landfill leachate collection systems, including filtration, drainage, and protection against clogging. By incorporating geocomposites, the leachate collection system can effectively collect and transport leachate, preventing its migration into the surrounding environment and minimizing potential environmental risks.

- Q: What is the course of civil engineering materials?

- First of all, if you are studying the basic nature of the most basic civil materials (such as concrete, gravel, etc.), how these materials such as mix ratio and particle size affect their performance, as well as the details of these materials Division, after learning this has a general understanding of this.

Send your message to us

Polypropylene Fiber 12mm for Concrete Use

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords