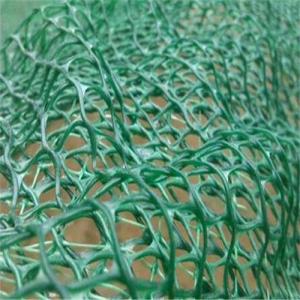

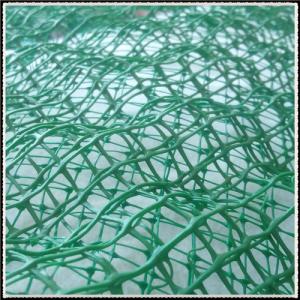

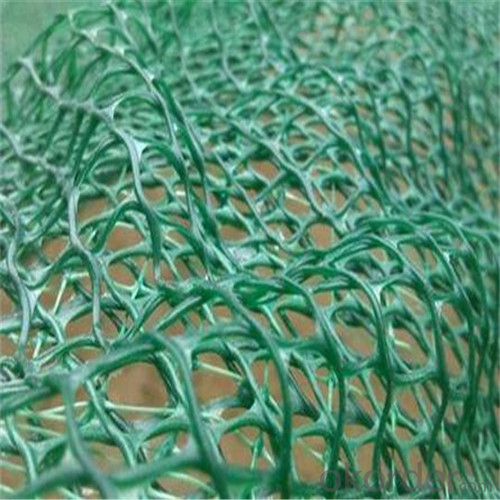

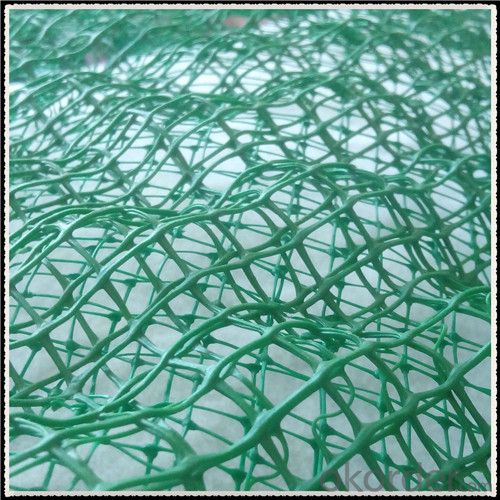

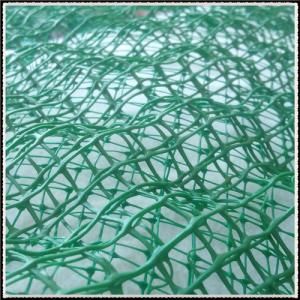

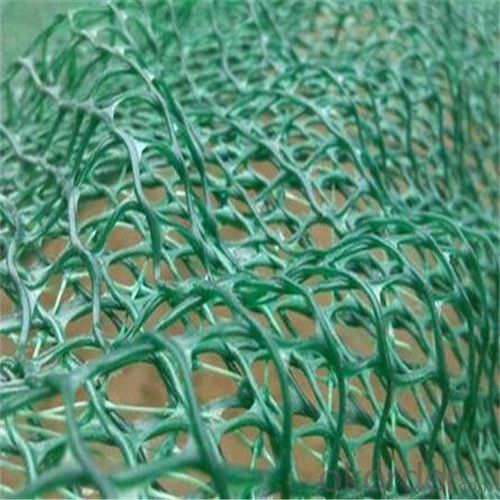

Geomat 3D Mesh and Geonet for Erosion Control

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geomat Description:

Geonet/Geomat is made from a kind of high-density polyethylene (HDPE) with properties of anti-aging and anticorrosion.

3D geomat erosion control mat is a kind of high polymer synthetic material made of 3D mesh structure, quality of a material is loose, flexible, with 90% of the space can fill soil,sand,the roots of the plants are grown through them balanced, the growth of grass make gauze pad, turf, soil surface firmly together, because the plant roots can be extended into the surface of the 30-50 cm, so the formation of a solid layer of green composite coating.

Geomat Specification:

CE121,CE131, CE151, DN1, HF10

Geomat Property:

1)Uniform structure, bear high pressure, improve the roadbed bearing capacity, enlarge its lifetime

2)Anti-aging, protect dam and rock surface from chemical erosion and sea water corrode.

Geomat Application:

1.Before the greensward grows, it prevents the surface of the land from the erosion of the wind and rain.

2 .Form compound protection layer with the vegetable, standing the wash-out of the high water level and large speed current.

3.Replace the concrete, asphalt, and block, using in the slope surface protection of roadway, railway, river-way, dyke, and the hillside, etc.

- Q: What are the advantages of using gabion walls?

- There are several advantages of using gabion walls. Firstly, they are highly durable and can withstand various environmental conditions, including heavy rainfall and erosion. Secondly, gabion walls are flexible and can easily adapt to the natural terrain, making them suitable for uneven surfaces. Additionally, they provide excellent drainage, preventing water buildup and reducing the risk of flooding. Moreover, gabion walls are cost-effective compared to traditional concrete or brick walls, as they require less maintenance and can be constructed using locally available materials. Lastly, these walls are eco-friendly, as they allow for vegetation growth and support wildlife habitats.

- Q: Can geosynthetics be used for lining water storage tanks?

- Yes, geosynthetics can be used for lining water storage tanks. They are commonly used as liners in various applications, including water storage tanks, due to their excellent durability, impermeability, and resistance to chemicals. Geosynthetics provide an effective barrier that prevents leakage and contamination, ensuring the integrity and safety of the water storage system.

- Q: What are the key considerations when using geotextile mats for erosion control on hiking trails?

- When using geotextile mats for erosion control on hiking trails, key considerations include the durability and strength of the mats, their ability to allow water drainage while preventing soil erosion, proper installation techniques to ensure optimal effectiveness, environmental sustainability and compatibility, and regular maintenance to monitor their condition and address any issues that may arise.

- Q: How do earthwork products contribute to groundwater pollution prevention?

- Earthwork products, such as geotextiles and geomembranes, play a crucial role in preventing groundwater pollution. These products are used in construction and landscaping projects to create barriers and liners that prevent contaminants from seeping into the ground and reaching the groundwater. By providing a protective barrier, earthwork products help to contain pollutants and prevent their migration, thus safeguarding the quality of groundwater resources.

- Q: How do earthwork products contribute to soil stabilization?

- Earthwork products, such as geotextiles and geogrids, contribute to soil stabilization by providing reinforcement and support to the soil. These products are installed within the soil layers to increase its strength, prevent erosion, and improve overall stability. Geotextiles act as a barrier, reducing the movement of soil particles and enhancing filtration, while geogrids provide structural reinforcement by distributing the load across a broader area. Both products help to control soil erosion, maintain slope stability, and enhance the longevity of earthwork structures.

- Q: What are the different types of concrete barriers?

- There are several types of concrete barriers commonly used, including Jersey barriers, F-shape barriers, K-rail barriers, and New Jersey barriers.

- Q: How do earthwork products affect the overall aesthetics of a project?

- Earthwork products can greatly impact the overall aesthetics of a project as they contribute to the visual appeal and harmony of the landscape. The choice of earthwork products, such as soil, rocks, and vegetation, can determine the texture, color, and shape of the landforms. Proper selection and arrangement of these elements can enhance the visual appeal, create focal points, and complement the surrounding environment, resulting in a more visually pleasing and cohesive project design.

- Q: What are the different patterns available in earthwork products?

- There are several different patterns available in earthwork products, including but not limited to, herringbone, basket weave, running bond, and random patterns. These patterns can add visual interest and variety to outdoor spaces and are often used in paving, landscaping, and construction projects.

- Q: What are the benefits of using geocells in green infrastructure projects?

- Geocells offer several benefits when used in green infrastructure projects. Firstly, they provide structural support and stability to the soil, preventing erosion and slope failure. This is especially important in areas with heavy rainfall or steep slopes. Secondly, geocells enhance drainage and water infiltration, reducing the risk of flooding and improving overall water management. Additionally, these cells promote vegetation growth by providing a stable environment for roots to anchor and access nutrients. Lastly, geocells are cost-effective and easy to install, making them an efficient solution for creating sustainable green infrastructure.

- Q: How do earthwork products help with soil remediation?

- Earthwork products, such as geotextiles and geosynthetics, play a vital role in soil remediation processes. These materials are designed to enhance the performance and effectiveness of soil remediation techniques. Geotextiles provide reinforcement, filtration, and erosion control, while geosynthetics offer containment and barrier functions. When used in soil remediation, geotextiles can help stabilize and reinforce the soil, preventing erosion and soil loss during excavation and backfilling. They also act as a filtering layer, allowing water to pass through while retaining contaminants, preventing their spread to surrounding areas. Moreover, geotextiles can aid in the growth of vegetation, promoting the restoration of the remediated soil. Geosynthetics, on the other hand, are often used as liners or barriers in soil remediation projects. They help contain and isolate contaminants, preventing them from leaching into the groundwater or spreading to nearby soil. Geosynthetics also provide a protective layer, minimizing the exposure of underlying soil to harmful substances. Overall, earthwork products contribute to the success of soil remediation by improving the stability, filtration, containment, and barrier functions of the soil, ensuring a more efficient and sustainable remediation process.

Send your message to us

Geomat 3D Mesh and Geonet for Erosion Control

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords