3D Geonet with High-Density Polyethylene (HDPE) and Ultravioresistant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specification---3D Geomat

3D Geomat ( three dimensional erosion control mat)

Introduction:

It is a kind of new 3D structural geosynthetics , which is applied in water and soil conservation

Features: Preventing soil erosion, increasing the greening area and improving the ecological environment

Function:

1.Before the greensward grows, it prevents the surface

of the land from the erosion of the wind and rain.

2 .Form compound protection layer with the plant ,

standing the wash-out of the high water level and large speed current.

3.Replace the concrete, asphalt, and block, using in the slope surface protection of roadway, railway, river-way, dyke, and the hillside, etc.

Properties of 3D Geomat ( three dimensional erosion control mat):

Spec Item | EM2 | EM3 | EM4 | EM5 |

Mass per unit area(g/㎡)≥ | 220 | 260 | 350 | 430 |

Thickness(mm)≥ | 10 | 12 | 14 | 16 |

Width(m)≥ | 2 | |||

Length(m)≥ | 30 | |||

Longitudinal tensile strength(KN/m)≥ | 0.8 | 1.4 | 2.0 | 3.2 |

Transverse tensile strength(KN/m)≥ | 0.8 | 1.4 | 2.0 | 3.2 |

Note: The special spec or size can be manufactured according to the demands of the contract | ||||

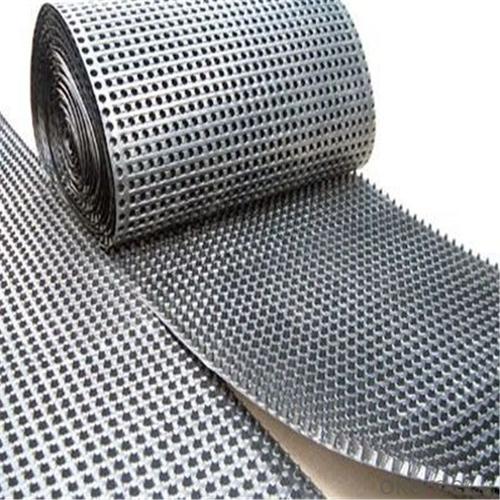

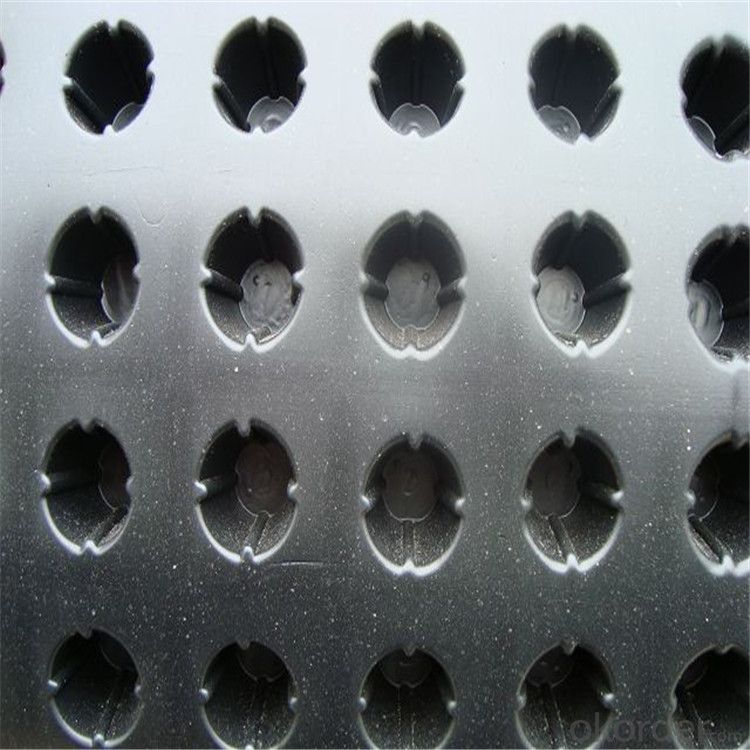

Properties of geonet

Item Spec | CE121 | CE131 | CE151 | CE181 | DN1 | HF10 |

Mass per unit area (g/㎡) | 730±35 | 630±30 | 550±25 | 700±35 | 750±35 | 124±60 |

Mesh size (mm) | (8±1)× (8±1) | (27±2)× (27±2) | (74±5)×(74±5) | (90±10)×(90±10) | (10±1)×(10±1) | (10±1)×(6±1) |

Width(m) | 2 or 2.5 | |||||

Length(m) | 50 or 40 | |||||

Maximum tensile strength (KN/m)≥ | 6.2 | 5.8 | 5.0 | 5.77 | 6.0 | 18 |

Note: The special spec or size can be manufactured according to the demands of the contract

Application:

1. Using the geonet on the roadbed of the roadway and railway can distribute the load effectively, improve the loading capacity and the stability of the roadway, and prolong its service life.

2. Spreading the geonet on the slope of road can prevent landslides, conserve water and soil, beautify the environment.

3. Spreading the geonet in the dyke protection in the reservoir and the river can protect it from the landslide.

4. Using the geonet in the coast engineering can amortize the concussion and the erosion of the

Images of Geonet

- Q: What are the challenges in installing and maintaining geosynthetic products in earthwork?

- Some challenges in installing and maintaining geosynthetic products in earthwork include ensuring proper placement and alignment of the materials, preventing damage during installation, ensuring adequate compaction and consolidation of the surrounding soil, and addressing issues such as settling, erosion, and shifting over time. Additionally, regular inspections and maintenance are necessary to identify and address any potential issues or damages to the materials, as well as to ensure the long-term effectiveness and performance of the geosynthetic products.

- Q: What is the purpose of using geonets in groundwater recharge systems?

- The purpose of using geonets in groundwater recharge systems is to enhance the infiltration and distribution of water into the ground. Geonets help to improve the efficiency of recharge systems by providing a stable and permeable surface that allows water to seep into the underlying soil or aquifer while preventing clogging or erosion. They also help to evenly distribute the water, reducing the chances of localized flooding or pooling. Overall, geonets play a crucial role in maximizing the recharge capacity and effectiveness of groundwater recharge systems.

- Q: What are the different applications of geogrids in road and railway construction?

- Geogrids are extensively used in road and railway construction for various applications. They are primarily utilized to enhance the stability and load-bearing capacity of the construction materials. Geogrids are used in the following areas: 1. Subgrade reinforcement: Geogrids are placed within the subgrade soil to improve its strength and prevent it from excessive settlement. They distribute the load more evenly, enhancing the stability of the road or railway. 2. Embankment reinforcement: Geogrids are employed in embankments to provide reinforcement and prevent slope failures. They help in controlling the lateral movement of soil, reducing the chances of erosion and maintaining the integrity of the embankment. 3. Base course stabilization: Geogrids are used in the base course of roads and railways to improve their strength and durability. They reduce the deformation and increase the load-bearing capacity of the base course materials, minimizing the chances of rutting and pavement failure. 4. Retaining wall reinforcement: Geogrids are employed in the construction of retaining walls to add stability and strength. They prevent the lateral movement of soil behind the wall, reducing the risk of wall failure and maintaining its structural integrity. 5. Slope stabilization: Geogrids are used to stabilize slopes and prevent erosion and landslides. They reinforce the soil structure, preventing it from sliding down the slope and ensuring its stability. Overall, geogrids play a crucial role in road and railway construction by improving the strength, stability, and longevity of the structures, enhancing their performance and reducing maintenance costs.

- Q: Are earthwork products suitable for agricultural applications?

- Yes, earthwork products are suitable for agricultural applications. These products, such as soil amendments, mulch, and erosion control materials, can greatly benefit agricultural practices by improving soil quality, preventing erosion, and conserving water. They provide essential support for crop growth, increased yields, and overall sustainability in agricultural operations.

- Q: How are gabion baskets filled and installed?

- Gabion baskets are filled and installed by first assembling the wire mesh baskets at the desired location. Then, stones or other suitable fill materials are placed inside the baskets until they are completely filled. The baskets are typically stacked and interconnected using wire or clips to create a strong and stable structure. Finally, the filled and interconnected gabion baskets are securely anchored to the ground or structure to ensure stability and integrity.

- Q: Are earthwork products suitable for use in pipeline construction?

- Yes, earthwork products are suitable for use in pipeline construction. Earthwork products such as soil, gravel, and crushed stone are commonly used in pipeline construction for backfilling and providing stable support to the pipeline. These materials help to prevent ground movement, erosion, and provide a solid foundation for the pipeline, ensuring its stability and longevity. Additionally, earthwork products can be engineered and compacted to meet specific requirements and ensure the pipeline's integrity.

- Q: How do geopipes help in stormwater management?

- Geopipes play a crucial role in stormwater management by effectively collecting and conveying excess rainwater away from urban areas. These pipes, made from durable materials like high-density polyethylene (HDPE), are designed with perforations that allow water to enter and be transported to designated areas for proper drainage and disposal. Geopipes prevent flooding and waterlogging by efficiently directing stormwater away from structures and roads, helping to minimize potential damage and keep the environment safe.

- Q: What are the advantages of using geotextile tubes for shoreline protection?

- Geotextile tubes offer several advantages for shoreline protection. Firstly, they are an environmentally friendly option as they use natural materials and do not harm marine life. Secondly, they are cost-effective compared to traditional methods like concrete or rock armor. Additionally, geotextile tubes are flexible and adaptable, making them suitable for various shoreline types and conditions. They provide effective erosion control and can be easily installed and removed, minimizing disruption to the natural habitat. Lastly, these tubes are durable, resistant to UV rays, and can withstand harsh weather conditions, ensuring long-term protection for shorelines.

- Q: Can earthwork products be used in agricultural applications?

- Yes, earthwork products can be used in agricultural applications. They can be used for various purposes such as land leveling, soil stabilization, erosion control, and drainage management. For example, products like geotextiles, geomembranes, and geocells can be used to reinforce soil, prevent erosion, and improve water containment in agricultural fields. Additionally, earthwork machinery such as excavators and bulldozers can be used for activities like land clearing and terracing, which are essential in agricultural practices.

- Q: How can geotextile bags be used in riverbank protection?

- Geotextile bags can be used in riverbank protection by creating a barrier against erosion. These bags are filled with sand or soil and placed along the riverbank to absorb the energy of flowing water, preventing erosion and stabilizing the soil. The geotextile material allows water to pass through while retaining the soil particles, effectively protecting the riverbank from being washed away.

Send your message to us

3D Geonet with High-Density Polyethylene (HDPE) and Ultravioresistant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches