White Color Polypropylene Staple Fiber 1.2D-1.5D

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Viscose Staple Fiber is natural, renewable, environmentally green cellulose fiber, with strong vitality. A wide range of uses include; spinning, weaving, garden machines, non-woven fabrics, as well as other fields. Our 100% viscose staple fiber is available in bright, semi-extinction, high white, high strength short as well as various lengths.

Technical Data of Polypropylene Staple Fiber

NO. | ITEM | UNIT | 1.7~3.3 DTEX | 3.4~7.8 DTEX | ||||||

TOP | GRADE.1 | GRADE.2 | GRADE.3 | TOP | GRADE.1 | GRADE.2 | GRADE.3 | |||

1 | Break Strength | Cn/dtex | ≥4.0 | ≥3.5 | ≥3.2 | ≥2.9 | ≥3.5 | ≥3.0 | ≥2.7 | ≥2.4 |

2 | Elongation | % | ≤60.0 | ≤70.0 | ≤80.0 | ≤90.0 | ≤70.0 | ≤80.0 | ≤90.0 | ≤100.0 |

3 | Linear density deviation | % | ±3.0 | ±8.0 | ±8.0 | ±10.0 | ±4.0 | ±8.0 | ±10.0 | ±12.0 |

4 | Length deviation | % | ±3.0 | ±5.0 | ±7.0 | ±9.0 | - | - | - | - |

5 | Defect | mg/100g | ≤5.0 | ≤20.0 | ≤40.0 | ≤60.0 | ≤5.0 | ≤25.0 | ≤50.0 | ≤70.0 |

6 | over-length fibre | mg/100g | ≤5.0 | ≤20.0 | ≤40.0 | ≤60.0 | ≤5.0 | ≤20.0 | ≤40.0 | ≤60.0 |

7 | over-length fibre rate | % | ≤0.5 | ≤1.0 | ≤2.0 | ≤3.0 | - | - | - | - |

8 | The number of curl | / 25mm | M1±2.5 | M1±3.0 | M1±3.5 | M1±4.0 | M1±2.5 | M1±3.0 | M1±3.5 | M1±4.0 |

9 | Curl rate | % | M2±2.5 | M2±3.0 | M2±3.5 | M2±4.0 | M2±2.5 | M2±3.0 | M2±3.5 | M2±4.0 |

10 | Resistivity | Ω.cm | ≤kX10^7 | ≤kX10^9 | ≤kX10^9 | ≤kX10^9 | ≤kX10^8 | ≤kX10^9 | ≤kX10^9 | ≤kX10^9 |

11 | Oil content | % | M2±0.10 | - | - | - | M3±0.10 | - | - | - |

12 | Coefficient of variation of breaking strength(cv) | % | ≤10.0 | - | - | - | - | - | - | - |

Specifications of Polypropylene Staple Fiber

1). polyester fiber from 1.2D-1.5D

2). polyester fiber length from 32-102 mm

3). widely used in carpet,spinning yarns,non-weaving,thermal bonding

4). color:raw white

5). specifications: 1.2D*38MM,1.3D*38MM,1.4D*38MM,1.5D*38MM

6).packing:plastic braided bag

7).grade:virgin,recycle

Advantage

1.Product Range:We can produce any your requirement(polyester staple fiber Fineness,length,color)

2.Good Service:We treat clients as friend

3.Good Quality:We have strict quality control system.Good reputation in the market.

4.Fast Delivery Date:Within 10 days after receive your payment or original L/C.

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

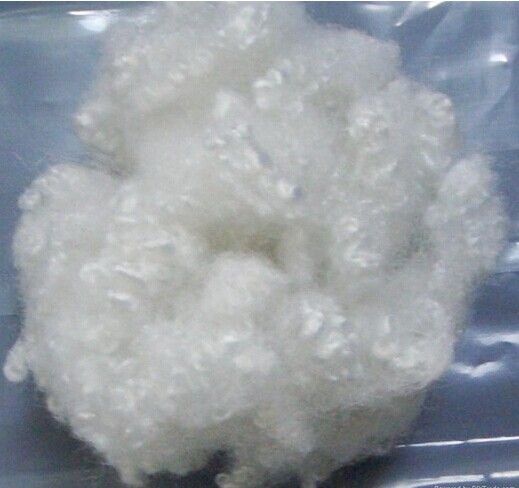

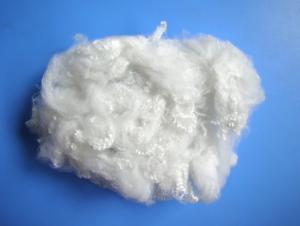

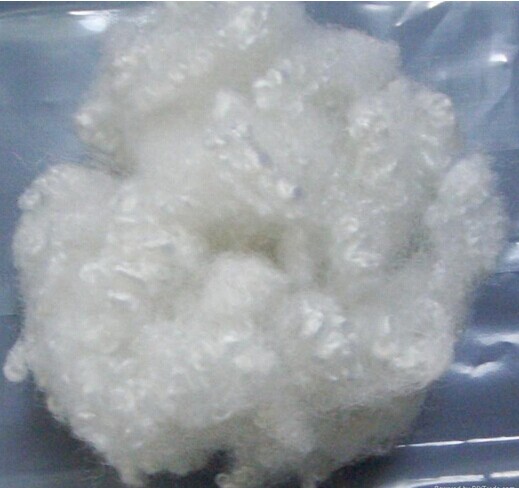

Product Photos of Polypropylene Staple Fiber

- Q: How do earthwork products contribute to LEED certification?

- Earthwork products, such as recycled aggregates, topsoil, and mulch, can contribute to LEED (Leadership in Energy and Environmental Design) certification in several ways. Firstly, using these products in construction projects reduces the demand for virgin materials, promoting resource conservation and minimizing environmental impact. Additionally, earthwork products can help improve the energy efficiency of buildings by providing better insulation and reducing the need for heating or cooling. Moreover, using recycled or locally sourced earthwork products can contribute to regional priority credits, which are specific to the project's location and encourage sustainable practices. Overall, incorporating earthwork products in construction projects aligns with the LEED principles of sustainability, resource efficiency, and environmental stewardship, making them an important factor in achieving LEED certification.

- Q: Brief description of the application range of Portland cement, ordinary cement, slag cement, volcanic ash cement and fly ash cement

- Slag Portland cement (referred to as slag cement), volcanic ash Portland cement (referred to as volcanic ash cement) and fly ash Portland cement (referred to as fly ash cement) are made of cement clinker. Mixed with the amount of gypsum made of fine. Wherein the variety and the content of the mixed material are different. The mixed material of the slag cement is granulated blast furnace slag, and the blending amount is 20% ~ 70% by weight; the mixed material of the volcanic ash cement is a mixed material of volcanic ash, the dosage is 20% ~ 50% by weight; Fly ash cement in the mixed material is fly ash, blending by weight percentage of 20% to 40%.

- Q: How do geosynthetic liners prevent contamination in waste containment facilities?

- Geosynthetic liners act as a barrier between the waste and the surrounding environment, preventing the contamination of soil, groundwater, and surface water. These liners are impermeable, meaning they do not allow liquids or pollutants to pass through them. This prevents the leaching of hazardous substances from the waste into the surrounding ecosystem, ensuring the protection of the environment and human health.

- Q: Can earthwork products be used for reservoir construction?

- Yes, earthwork products can be used for reservoir construction. These products, such as soil, clay, and gravel, are commonly used in the construction of reservoirs to create embankments, berms, and containment structures. The earthwork materials can help to stabilize the reservoir's foundations, control erosion, and provide lining for the reservoir basin.

- Q: What are the advantages of using geosynthetic materials in airport runway construction?

- There are several advantages of using geosynthetic materials in airport runway construction. Firstly, geosynthetic materials offer improved stability and strength to the runway structure. These materials have high tensile strength and can withstand heavy loads, ensuring the runway can support the weight of aircrafts without excessive deformation or settlement. Secondly, geosynthetics provide effective drainage and water management. They have excellent filtration properties, allowing water to pass through while preventing soil particles from clogging the system. This helps in maintaining the integrity of the runway by preventing water accumulation and reducing the risk of erosion or weakening of the foundation. Additionally, geosynthetics offer enhanced soil reinforcement. By incorporating geotextiles or geogrids into the runway construction, the load-bearing capacity of the soil can be significantly increased. This allows for the use of weaker or less expensive soil materials, reducing the overall construction costs. Moreover, geosynthetic materials are easy to install and require less labor compared to traditional construction methods. They can be prefabricated off-site, reducing the construction time and minimizing disruptions to airport operations. This makes geosynthetic materials a cost-effective and efficient choice for runway construction. Overall, the use of geosynthetic materials in airport runway construction provides improved stability, effective drainage, enhanced soil reinforcement, and cost savings. These advantages make geosynthetics an ideal choice for ensuring the durability and longevity of airport runways.

- Q: How do erosion control blankets help in sediment control in earthwork projects?

- Erosion control blankets play a crucial role in sediment control in earthwork projects by providing a protective layer over exposed soil. They effectively minimize the impact of rain and wind on the soil surface, reducing erosion and preventing sediment runoff. Additionally, these blankets promote vegetation growth, stabilizing the soil further and enhancing sediment retention. Overall, erosion control blankets act as a physical barrier, preventing soil particles from being washed away and helping maintain the integrity of the project site.

- Q: What are the different applications of geosynthetic clay liners?

- Geosynthetic clay liners (GCLs) are widely used in various applications such as landfill liners, mining and industrial waste containment, canal and pond liners, and erosion control. They provide an impermeable barrier, preventing the migration of contaminants, and offer stability and erosion resistance in geotechnical engineering projects.

- Q: Can geotextiles be used for soil separation in earthwork projects?

- Yes, geotextiles can be used for soil separation in earthwork projects. Geotextiles are permeable fabrics that are commonly used to separate different layers of soil in order to prevent mixing and maintain the stability of the project. They are effective in preventing the migration of fine particles and providing reinforcement, making them a suitable choice for soil separation in earthwork projects.

- Q: Can geocells be used for load support in railways?

- Yes, geocells can be effectively used for load support in railways. Geocells are three-dimensional cellular confinement systems made from high-density polyethylene materials, which can be filled with various infill materials like sand, gravel, or soil. These geocells provide structural stability and distribute the load evenly, preventing lateral movement and settlement of the railway track. They enhance the overall load-bearing capacity, reduce vertical deformation, and improve the longevity of the railway infrastructure.

- Q: How are geotextile tubes used in sediment control during construction projects?

- Geotextile tubes are commonly used in sediment control during construction projects as they provide an effective solution for containing and dewatering sediment-laden water. By placing these tubes strategically, they act as barriers, preventing sediment from contaminating nearby water bodies or flowing downstream. The sediment-laden water is pumped into the tubes, where the geotextile fabric allows water to drain out while retaining the sediment within the tube. This process helps to promote water quality and protect the surrounding environment during construction activities.

Send your message to us

White Color Polypropylene Staple Fiber 1.2D-1.5D

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords