Polypropylene Fiber for Reinforcement with 12mm 18mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PP Fiber Introduction

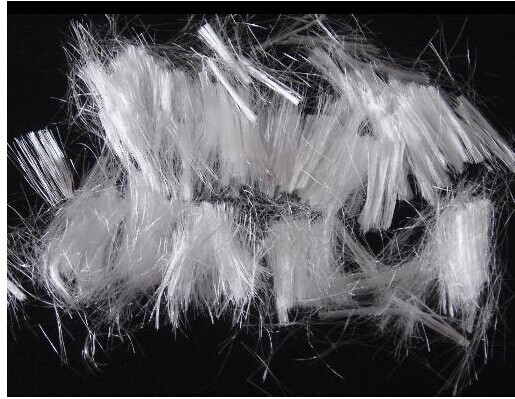

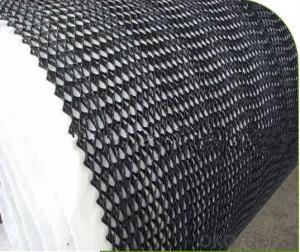

Polypropylene fiber also called PP fiber, is a new type of reinforcing and crack-resistant building material for bitumen concrete reinforcement. It is produced by special technique.With polypropylene as its raw material,fiber-mesh is produced by special technology.It appears net-like structure with many monofilaments connected.

The horizontal structure in monofilament can be destroyed in the course of the stirring owng to friction and rubbing,and the monofilament or net like structure will fully stretch, thus the concrete is reinforce by a great number(more than 7 million pieces per cubic meter) of polypropylene fibers.

Technical Data of Polypropylene Fiber for Reinforcement with 12mm 18mm

Raw Material | Polypropylene | Crack Elongation | 20%±5% |

Type | Monofilament | Density | 0.91±0.01g/cm3 |

Fiber Diameter | 0.02-0.05±0.005mm | Melting point | 160-170 |

Tensile strength | ≥450mpa | Resistance to acid, alkali | Strong |

Size | 6, 12, 10, 15, 19, 20, 24, 48mm | Water absorbency | no |

Product Function of Polypropylene Fiber for Reinforcement with 12mm 18mm

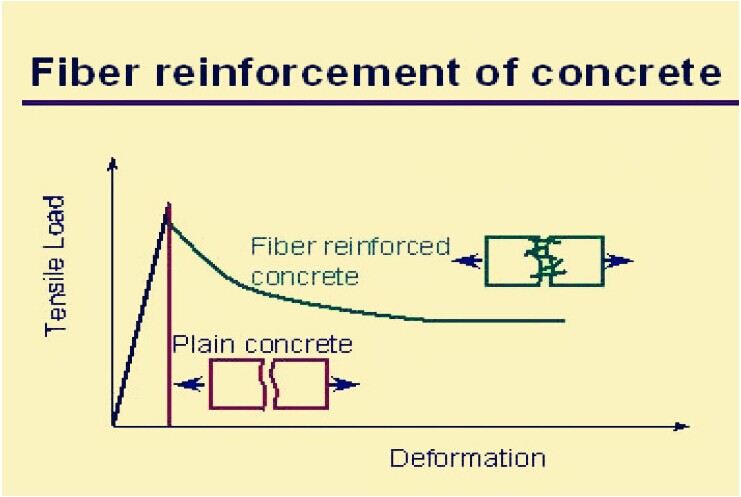

1) improve the crack resistance of mortar and concrete

2) improve the permeability resistance of mortar and concrete greatly

3) improve mortar, concrete resistance to impact, bending and seismic performance

4) improve wear resistance of mortar and concrete

5) improve the antifreeze performance of mortar and concrete

6) strong dispersion, workability

7) good chemical stability, acid and alkali resistant capability is strong, safe non-toxic, for reinforcement corrosion damage

FAQ

1. Which payment do you accept?

For you convinience,our payment can be L/C,TT

2. Is free sample available?

We can supply free samples if you need.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world

Product effect Photo of Polypropylene Fiber for Reinforcement with 12mm 18mm

4. Product Application of Polypropylene Fiber for Reinforcement with 12mm 18mm

1), building engineering, mortar, concrete structure of civil and industrial buildings, including site casting, beam-column, the basement floor and side panel, roof cast-in-place floor slab, pool structure, crack resistance, impact resistance, high wear resistance requirements of engineering.

2), municipal engineering, concrete road and square, bridge, tunnel, subway, port terminals, interchange bridge, bridge, airport runway, super long structure, etc.

3), water conservancy project: levees, DAMS, etc.

4), antiknock, refractory engineering: civil air defense, military engineering, oil platform, chimneys, refractory materials, etc.

5), shotcrete, tunnel, culvert lining, thin-walled structure, slope reinforcement, etc.

5. Product Show of Polypropylene Fiber for Reinforcement with 12mm 18mm

- Q: What are the benefits of using geotextile mats in road maintenance?

- Geotextile mats offer several benefits in road maintenance. Firstly, they provide erosion control by stabilizing the soil and preventing its movement, thereby reducing the need for frequent repairs. Secondly, these mats improve road strength and durability by distributing load and reducing stress on the pavement, resulting in extended service life. Additionally, geotextile mats act as a barrier, preventing the intrusion of fine particles into the road base, which can lead to weakening and deterioration. Lastly, these mats are easy to install and require minimal maintenance, making them a cost-effective solution for road maintenance projects.

- Q: What are the different thicknesses available for earthwork products?

- The thicknesses available for earthwork products can vary depending on the specific product, but common thicknesses range from a few inches to several feet.

- Q: Can earthwork products be used for decorative purposes?

- Yes, earthwork products can be used for decorative purposes. They can be transformed into various forms such as sculptures, landscape features, or even used in creating textured finishes for walls or floors. Additionally, earthwork products like clay or adobe can be utilized in the construction of aesthetically pleasing structures like earthen homes or artistic installations.

- Q: Are earthwork products resistant to chemical corrosion?

- Yes, earthwork products, such as soil and rocks, are generally resistant to chemical corrosion. However, the extent of their resistance may vary depending on the specific chemical substances and their concentrations.

- Q: How do earthwork products contribute to stormwater infiltration?

- Earthwork products, such as permeable pavers and bioretention systems, play a crucial role in stormwater infiltration. Permeable pavers, with their porous structure, allow rainwater to pass through and infiltrate into the ground, replenishing groundwater resources. Similarly, bioretention systems, like rain gardens and bioswales, use vegetation and engineered soils to capture and filter stormwater, promoting infiltration and reducing runoff. By facilitating stormwater infiltration, these earthwork products help mitigate flooding, improve water quality, and restore the natural hydrological cycle.

- Q: Are earthwork products easy to install?

- Yes, earthwork products are generally easy to install. They are designed to be user-friendly and often come with clear installation instructions. Additionally, many earthwork products do not require specialized tools or skills, making the installation process relatively straightforward for both professionals and DIY enthusiasts.

- Q: What are the civil works?

- The professional training of engineering mechanics, fluid mechanics, geotechnical and municipal engineering disciplines of the basic theory and basic knowledge, with civil engineering in the project planning, design, research and development, construction and management capacity, in the housing construction, underground construction Such as design, research, construction, education, management, investment and development of tunnels, roads, bridges, mines and other senior technical and technical personnel engaged in technical or management work. The students mainly study the basic theory of engineering mechanics, fluid mechanics, geotechnical mechanics and municipal engineering disciplines, and are trained in curriculum design, test equipment operation and field practice. They are engaged in the planning, design, research and construction of civil engineering , The basic ability to manage.

- Q: How do earthwork products contribute to slope stability?

- Earthwork products, such as geotextiles and geogrids, play a crucial role in enhancing slope stability. These products are used to reinforce and stabilize the soil in a slope, preventing erosion and reducing the risk of slope failure. Geotextiles are permeable fabrics that are placed between soil layers to improve their strength and prevent soil particles from getting washed away by water. Geogrids, on the other hand, are mesh-like structures that provide tensile strength to the soil, increasing its resistance to shearing and sliding. By reinforcing the soil, earthwork products help maintain the integrity of slopes, ensuring their long-term stability.

- Q: Can earthwork products be used for constructing boat ramps?

- Yes, earthwork products such as soil, gravel, and rocks can be used for constructing boat ramps. These materials can be used to build the base and slope of the ramp, providing stability and traction for boats during launching and loading. Additionally, earthwork products can be shaped and compacted to create a smooth and durable surface for boat ramp construction.

- Q: How do geosynthetic products contribute to soil erosion prevention in orchards?

- Geosynthetic products play a crucial role in preventing soil erosion in orchards. These specially designed materials, such as geotextiles, geogrids, and geocells, offer effective erosion control measures by stabilizing the soil, improving its water permeability, and providing reinforcement against potential erosion forces. They help retain soil particles in place, reduce runoff, and enhance water infiltration, thus ensuring the stability and preservation of orchard soils and preventing erosion damage.

Send your message to us

Polypropylene Fiber for Reinforcement with 12mm 18mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords