Geonet with High-Density and Ultravioresistant,ISO and CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

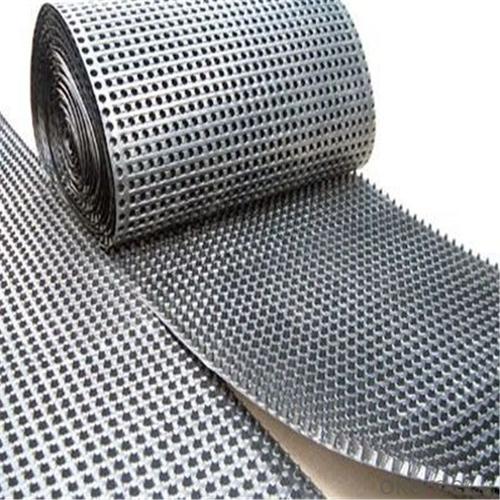

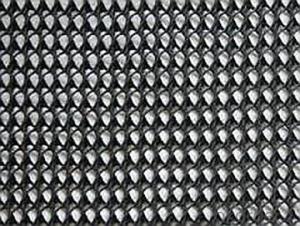

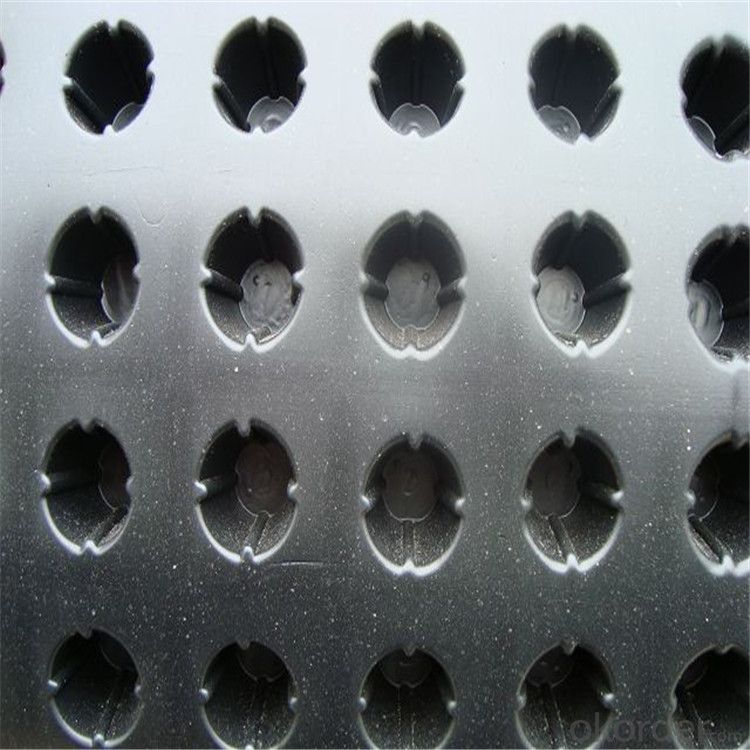

Geonet is made of high-density polyethylene (HDPE) and the ultravioresistant

Application:

1. Using the geonet on the roadbed of the roadway and railway can distribute the load effectively, improve the loading capacity and the stability of the roadway, and prolong its service life.

2. Spreading the geonet on the slope of road can prevent landslides, conserve water and soil, beautify the environment.

3. Spreading the geonet in the dyke protection in the reservoir and the river can protect it from the landslide.

4. Using the geonet in the coast engineering can amortize the concussion and the erosion of the

surf

Properties of geonet

Item Spec | CE121 | CE131 | CE151 | CE181 | DN1 | HF10 |

Mass per unit area (g/㎡) | 730±35 | 630±30 | 550±25 | 700±35 | 750±35 | 124±60 |

Mesh size (mm) | (8±1)× (8±1) | (27±2)× (27±2) | (74±5)×(74±5) | (90±10)×(90±10) | (10±1)×(10±1) | (10±1)×(6±1) |

Width(m) | 2 or 2.5 | |||||

Length(m) | 50 or 40 | |||||

Maximum tensile strength (KN/m)≥ | 6.2 | 5.8 | 5.0 | 5.77 | 6.0 | 18 |

Note: The special spec or size can be manufactured according to the demands of the contract

Images of Geonet

- Q: What are the benefits of using geosynthetic materials in slope stabilization for highways?

- Using geosynthetic materials in slope stabilization for highways offers several benefits. Firstly, these materials provide increased stability to slopes and embankments, reducing the risk of landslides and erosion. This enhances the safety of the highway and minimizes the potential for accidents or disruptions caused by slope failures. Additionally, geosynthetics offer cost-effective solutions compared to traditional methods used in slope stabilization. They are lightweight and easy to install, resulting in reduced construction time and labor costs. Moreover, geosynthetic materials are durable and resistant to environmental factors such as moisture and UV degradation, ensuring long-term effectiveness and requiring minimal maintenance. Furthermore, these materials facilitate proper drainage by allowing water to flow through the slope while preventing excessive moisture buildup. This helps to maintain the stability of the slope and prevents water-related damage. Overall, the use of geosynthetic materials in slope stabilization for highways provides improved safety, cost savings, and long-term stability, making it a beneficial choice for infrastructure projects.

- Q: Are earthwork products suitable for underground storage systems?

- Yes, earthwork products like geotextiles, geogrids, and geomembranes are suitable for underground storage systems. These products provide reinforcement, stability, and waterproofing to the underground structures, ensuring their long-term durability and functionality.

- Q: Can earthwork products be used for constructing swimming pools?

- Yes, earthwork products can be used for constructing swimming pools.

- Q: What are the specific applications of geosynthetics in earthwork projects?

- Geosynthetics have various applications in earthwork projects, including erosion control, soil reinforcement, drainage systems, and waste containment. They are commonly used as geotextiles to prevent soil erosion and stabilize slopes, as geogrids to reinforce soil and improve load-bearing capacity, and as geocomposites for drainage and filtration purposes. Additionally, geosynthetics are utilized in the construction of landfills, reservoirs, and dams to provide effective containment of waste materials and water. Overall, geosynthetics play a crucial role in enhancing the performance, durability, and sustainability of earthwork projects.

- Q: Can earthwork products be used in foundation construction?

- Yes, earthwork products can be used in foundation construction. These products, such as soil, gravel, and sand, are commonly used in different stages of foundation construction to provide stability, support, and proper drainage.

- Q: Can geosynthetics be used for lining wastewater treatment plants?

- Yes, geosynthetics can be used for lining wastewater treatment plants. Geosynthetics, such as geomembranes and geotextiles, are commonly used to provide impermeable barriers and enhance the performance of lining systems in wastewater treatment facilities. They help to prevent leakage, control seepage, and protect the surrounding environment from potential contamination. Additionally, geosynthetics offer durability, flexibility, and cost-effectiveness, making them a suitable choice for lining wastewater treatment plants.

- Q: Can earthwork products be used for water containment systems?

- Yes, earthwork products can be used for water containment systems.

- Q: How do earthwork products contribute to carbon sequestration?

- Earthwork products, such as biochar and compost, contribute to carbon sequestration by acting as carbon sinks. When these products are added to soil, they enhance its ability to capture and store carbon dioxide from the atmosphere. Biochar, for instance, is a highly porous material that helps retain carbon in the soil for hundreds of years. Similarly, compost increases soil organic matter, improving its carbon storage capacity. By using earthwork products, we can enhance carbon sequestration in soils, mitigating climate change and promoting sustainable land management practices.

- Q: Can earthwork products be used for underground storage applications?

- Yes, earthwork products can be used for underground storage applications. These products, such as geotextiles, geomembranes, and geogrids, can provide effective containment and protection for various materials, including liquids, gases, and solid waste. They offer excellent strength, stability, and durability, making them suitable for constructing underground storage facilities like tanks, reservoirs, and landfills. Additionally, earthwork products can also help with proper drainage and environmental protection in underground storage applications.

- Q: How do geosynthetic liners prevent seepage in agricultural irrigation reservoirs?

- Geosynthetic liners act as a barrier between the soil and water in agricultural irrigation reservoirs, preventing seepage by effectively containing and controlling water flow. These liners are made of impermeable materials such as geomembranes or geotextiles, which do not allow water to pass through. By lining the reservoir with these materials, the liners prevent water from seeping into the soil, thus minimizing wastage and ensuring efficient water retention for agricultural irrigation purposes.

Send your message to us

Geonet with High-Density and Ultravioresistant,ISO and CE

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches