Sodium Bentonite Geosynthetic Clay Liner with ASTM Standard

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

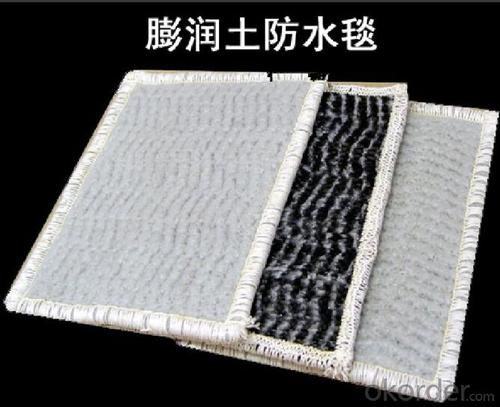

Sodium Bentonite Geosynthetic Clay Liner

Introduction of GCL:

Geosynthetic Clay Liner is manufactured

by three levels, including two levels of geotextile whose functions are protecting and strengthen to ensure shearing strength and tensile strength, inner content is Sodium bentonite clay. It is manufactured by nature layer silicate inorganic materials and has high expansibility and high water-absorbing capacity, when soak with low permeable capability, whose the main function is anti-seepage.

Description of GCL

Unit weight ≥4000gsm

width of 4-6m

Compared with clay liner ,it has the advantages of small size,light weight ,good flexibility and sea

easy for construction and suitable for uneven settlement.

GCL Feature:

1.The permanent waterproof

Because sodium base bentonite is a natural inorganic material, even after a long time or the surrounding environment changes,

also won't happen aging or corrosion phenomena, so the waterproof performance persistence.

2. Compactibility

Sodium base bentonite under water pressure condition to form diaphragm with high density, thickness of about 3 mm,

its permeability is 5 x 10-11m/SEC below, equivalent to 100 times the compactness of 30 cm thickness of clay,

have very strong since the water retention performance.

3.Not affected by temperature

In cold climates will not brittle fracture.

4.Environmental protection

Bentonite as natural inorganic material, non-toxic harmless to human body, no special effects to the environment,

have good environmental performance.

5.Simple and short time of construction

Compared to other waterproofing materials, construction is relatively simple, don't need to be heated and paste.

With bentonite powder and nails, washers, etc are connected and fixed. After construction does not need special

inspection, if it is found that the waterproof defects and easy to maintenance.

GCL is existing waterproof material in construction period of the shortest.

Specifications

| Property | National standard | Enterprise Standard | Inspection standards |

| JG/T 193-2006 | |||

| Geosynthetic Clay Expansion index | ≥24 ml/2g | ≥25ml/2g | ASTM D5890 |

| Mass Per Unit Area(g/m2) | ≥4000 g/m2 | ≥4000 gm2 | ASTM D5993 |

| Tensile Strength | ≥6KN/m | ≥8KN/m | ASTM 4632 |

| Maximum load elongation | ≥10% | ≥10% | ASTM 4632 |

| Permeability | ≤5×10-11 | ≤5×10-11 | ASTM D5084 |

| Moisture content | ≤15% | ≤15% | ASTM D4643 |

| Peel strength | ≥40N | ≥65N | ASTM D4632 |

| Hydrostatic pressure | 0.4Mp | 0.4~0.6Mp | ASTM D5891 |

Application of GCL:

Mainly used in environmental engineering or landfill emissions underground reseroirs.underground

infrastructure construction projests sealing solution ,segregation ,anti-leakage,good effect,anti-

destructive

FAQ:

How many quantity for one 20'' container?

About 5,000m2, 16rolls

What's your delivery time?

About 15-20days against deposit received

. What's your package?

Per roll with two pieces woven bag

- Q: Are earthwork products suitable for bridge approach embankments?

- Yes, earthwork products are suitable for bridge approach embankments. Earthwork materials, such as soil, clay, or gravel, can be used to construct stable embankments that support the bridge approach. These materials can be compacted and shaped to provide a solid foundation and slope for the bridge approach, ensuring its stability and longevity.

- Q: What are the different sizes of earthwork products available?

- The sizes of earthwork products can vary depending on the specific project and requirements. Generally, earthwork products such as gravel, sand, and soil are available in different sizes ranging from fine to coarse. Gravel can come in sizes like 3/8 inch, ¾ inch, or 1 inch, while sand may be available in fine, medium, or coarse grades. Soil is typically classified into different types based on particle size, such as clay, silt, or sand. Ultimately, the size of earthwork products needed will depend on the intended use and specifications of the project.

- Q: How do geocomposites aid in soil filtration in earthwork projects?

- Geocomposites aid in soil filtration in earthwork projects by providing a barrier that allows water to pass through while effectively filtering out fine particles and contaminants. This helps to maintain the stability and integrity of the soil, preventing erosion and promoting better drainage.

- Q: A short duration of housing, and now have the same level of 42.5 for the silicate and slag cement selection. From the point of view of the completion of the construction period, what better cement should be used?

- Portland cement is better than the others

- Q: Can earthwork products be used for rainwater harvesting?

- Yes, earthwork products can indeed be used for rainwater harvesting. These products, such as trenches, berms, and swales, can be strategically designed and installed to help capture and channel rainwater into storage systems such as rain barrels, cisterns, or underground tanks. By using earthwork techniques, rainwater can be effectively collected and stored for later use, reducing water consumption and providing a sustainable source of water.

- Q: What are the benefits of using geosynthetic panels in slope stabilization?

- Using geosynthetic panels in slope stabilization offers several benefits. Firstly, these panels provide a strong and flexible reinforcement system, effectively distributing the weight and stress on the slope surface. This helps to prevent soil erosion and slope failure, ensuring long-term stability. Secondly, geosynthetic panels are easy to install, saving both time and labor costs. They can be quickly deployed, reducing the disruption to the surrounding environment. Additionally, these panels are durable and resistant to weathering, making them suitable for various climatic conditions. Lastly, geosynthetic panels are a cost-effective solution compared to traditional methods of slope stabilization, offering a sustainable and efficient option for managing slope stability.

- Q: What are the benefits of using geotextile mats in roadway reinforcement systems?

- Geotextile mats offer numerous benefits in roadway reinforcement systems. Firstly, they improve the stability and load-bearing capacity of the road by distributing the applied loads more evenly. This helps prevent rutting, potholes, and structural failures. Secondly, geotextile mats act as a barrier, preventing the mixing of base materials and subgrade soils, which reduces the risk of contamination and erosion. Additionally, these mats enhance drainage by allowing the passage of water while preventing the loss of fine particles. This helps to maintain the road's structural integrity and prevent water-related damages. Lastly, geotextile mats are cost-effective as they require minimal maintenance and prolong the lifespan of the roadway, reducing the need for frequent repairs and replacements.

- Q: How do geogrids aid in reinforcement of retaining walls in earthwork projects?

- Geogrids aid in the reinforcement of retaining walls in earthwork projects by providing additional strength and stability to the structure. They are typically made from high-strength materials such as polyester or polypropylene, and are placed within the soil layers to distribute the load more evenly. This helps to prevent the soil from sliding or collapsing, increasing the overall stability and longevity of the retaining wall.

- Q: How do geopipes help in onsite sewage disposal systems?

- Geopipes play a crucial role in onsite sewage disposal systems by efficiently collecting and transporting wastewater from houses or buildings to the septic tanks or treatment areas. These specially designed pipes are perforated, allowing for the drainage of liquid waste while preventing solids from entering. Geopipes also help in distributing the effluent evenly throughout the drain field, promoting proper filtration and treatment of the wastewater before it seeps into the soil.

- Q: The Relationship between Water Absorption and Water Content in Civil Engineering Materials

- The amount of water absorbed and the moisture balance in the air is usually less than the water absorption when the material in the air to reach saturation in the water, the water content and water absorption equal.

Send your message to us

Sodium Bentonite Geosynthetic Clay Liner with ASTM Standard

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords