Geogrids Que Son - PVC Coated Polyester Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

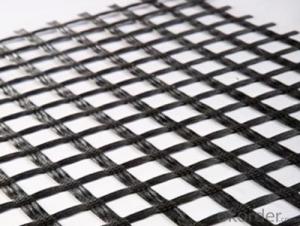

Structure of PVC Coated Polyester Geogrid Description:

PVC Coated Polyester Geogrd is Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal.

Main Features of PVC Coated Polyester Geogrid:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4.Prevent tunnel from crack occurring.

5.Further solidity slopes to proof water and soil from losses.

PVC Coated Polyester Geogrid Images

PVC Coated Polyester Geogrid Specification:

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used in reinforcement of soft ground?

- Yes, geogrids can be used in the reinforcement of soft ground. Geogrids are commonly used to improve the stability and load-bearing capacity of weak or soft soil by distributing the applied loads and reducing settlement. They are effective in reinforcing soft ground and can provide increased strength and stability to the soil, making them a suitable solution for various civil engineering and construction projects.

- Q: Are geogrids effective in reducing pavement rutting?

- Yes, geogrids are effective in reducing pavement rutting. They provide reinforcement to the pavement structure, distributing loads more evenly and improving its overall stability. By reducing the excessive movement of the underlying soil, geogrids help mitigate rutting and extend the lifespan of the pavement.

- Q: How do geogrids help in reducing maintenance costs?

- Geogrids help in reducing maintenance costs by providing reinforcement to the soil, increasing its stability and load-bearing capacity. This prevents the need for frequent repairs and maintenance due to soil erosion, settlement, or structural failures. Geogrids also improve drainage, reducing the accumulation of water and preventing damage to the infrastructure, thereby minimizing maintenance expenses in the long run.

- Q: Can geogrids be used in reinforcement of tunnels and underground excavations?

- Yes, geogrids can be used in the reinforcement of tunnels and underground excavations. Geogrids are commonly utilized in such applications to enhance soil stabilization, reduce soil movement, and provide structural support. They can effectively distribute the load and improve the overall stability and longevity of tunnels and underground excavations.

- Q: Are geogrids suitable for use in soil reinforcement for coastal protection structures?

- Yes, geogrids are suitable for use in soil reinforcement for coastal protection structures. Geogrids are commonly used in such applications as they provide excellent reinforcement to the soil, improving its stability and resistance against erosion caused by waves and tides. They offer high tensile strength, durability, and resistance to harsh environmental conditions. Additionally, geogrids can be easily installed and integrated into various coastal protection systems, making them an effective solution for reinforcing soil in coastal areas.

- Q: What is the meaning of reinforced subgrade? Is there a geogrid type on the road?

- Yes. But not necessarily the design of geogrid.

- Q: Are geogrids effective in reducing soil settlement?

- Yes, geogrids are effective in reducing soil settlement. They provide reinforcement and stabilization to the soil, preventing excessive settlement and maintaining the integrity of the ground. By distributing the load and increasing the load-bearing capacity of the soil, geogrids help to minimize settlement and ensure long-term stability.

- Q: What is the effect of creep on geogrid performance?

- The effect of creep on geogrid performance is that it can cause long-term deformation and reduced tensile strength over time. Creep refers to the gradual movement or deformation of a material under constant load or stress. In the case of geogrids, prolonged exposure to sustained load or stress can result in creep, leading to a loss of the geogrid's initial stiffness and load-bearing capacity. This can negatively impact its ability to provide soil reinforcement, stability, and confinement, compromising its overall performance in geotechnical applications. Therefore, creep considerations are crucial when designing and selecting geogrids for long-term projects.

- Q: How to determine the number of geogrid detection method

- 2) according to the design of the location, along the road to the laying of the grid, laying the grille, should pay attention to the connection between the grid and straightening smooth. Grille of the longitudinal and transverse joints can use nylon or polyester rope sewn or U nail connection method between the grid as a whole, grid overlapping width not less than 20cm, in the direction of the stress intensity of the joint shall not be less than the design tensile strength of materials. The grid distortion, fold, overlap, is not conducive to play its role, thus laying by hands straightened, the grid is smooth and uniform, geogrid every 1.5-2.0m paved with hook nail fixed on the ground.3) fill: after the completion of the grille, should be timely (48 hours) filling. Each layer should be carried out according to the principle of "the first two sides, the middle of the back". The packing is not allowed to be unloaded directly on the geogrid. It must be unloaded on the soil surface which has been paved. The soil unloading height is not more than 1m. All vehicles and construction machinery shall not be allowed to walk directly on the paved geogrid, but only to be allowed to travel along the axis of the embankment.4) the upper and lower sides of the geogrid, and 8 cm from the grid layer shall not be more than 6 cm in diameter.

- Q: Are geogrids suitable for use in mining tailings ponds?

- Yes, geogrids are suitable for use in mining tailings ponds. Geogrids provide excellent stability, erosion control, and reinforcement to the tailings pond structure. They help in preventing soil erosion, enhancing slope stability, and improving overall longevity of the pond. Additionally, geogrids can withstand harsh environmental conditions and are resistant to chemicals present in tailings, making them a reliable and effective solution for mining tailings ponds.

Send your message to us

Geogrids Que Son - PVC Coated Polyester Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords