Woven Polyester Geogrids - PP Biaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of PP Biaxial Geogrid Description:

PP Biaxial Geogrid Description is made of high polymer, which is extruded the thin sheet, then rushed the regular mesh and two ways extension. And the material has a high tensile strength, so it can also provide the ideal force bear and spread of the interlock systems for the soil, suitable for large area permanent load-bearing of groundwork.

Main Features of PP Biaxial Geogrid:

touch-screen display and parameter setting, imported piezoelectric ceramic transducer, the output strength and stability.

color display touch-screen control panel.

multi-language you set, easy to use.

levels of adjustable mold design, mold fast and easy adjustment.

the new power amplifier circuit, power is more robust, more durable transducers,

frequency automatic tracking, a variety of parameter settings.

High degree of automation in the domestic production of similar products in the leading position

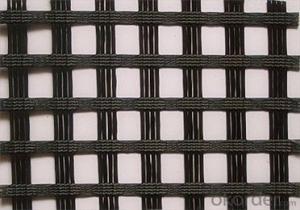

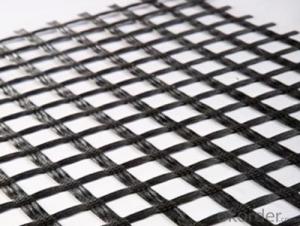

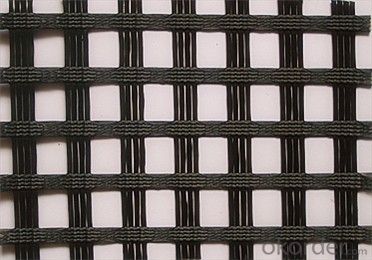

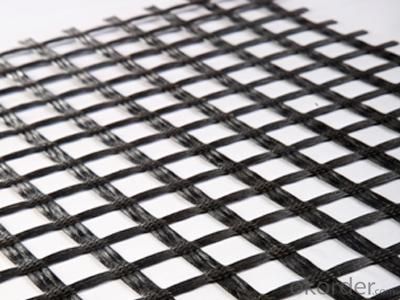

PP Biaxial Geogrid Images

PP Biaxial GeogridSpecification:

Item Model | TGSG15-15 | TGSG20-20 | TGSG25-25 | TGSG30-30 | TGSG35-35 | TGSG40-40 | TGSG45-45 | TGSG50-50 |

Width, m | 4.0 | |||||||

Yield strength KN/m≥ | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 |

Longitudinal elongation, %≤ | 15 | |||||||

Transverse elongation, %≤ | 13 | |||||||

Strength at 2% elongation, KN/m≥ | 5 | 7 | 9 | 10 | 12 | 14 | 16 | 17.5 |

Strength at 5% elongation, KN/m≥ | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Can geogrids be used in shoreline protection?

- Yes, geogrids can be used in shoreline protection. Geogrids are commonly used in erosion control and shoreline stabilization projects. They provide reinforcement to the soil and help prevent erosion, especially in areas where waves and currents are strong. Geogrids can be installed along the shoreline to stabilize the soil, reduce erosion, and protect the coastline from further damage.

- Q: Are geogrids effective in reducing pavement rutting?

- Yes, geogrids are effective in reducing pavement rutting. They provide reinforcement to the pavement structure, distributing loads more evenly and improving its overall stability. By reducing the excessive movement of the underlying soil, geogrids help mitigate rutting and extend the lifespan of the pavement.

- Q: Which instrument is used to measure the permeability of geotextiles?

- Is made of filament or staple through the equipment and technology of different laying into the mesh, after acupuncture process for different fiber intertwined intertwined fixing fabric specification, make the fabric soft, plump, thick, stiff, to achieve different thickness to meet the requirement of use

- Q: How do geogrids enhance the load-bearing capacity of pavements?

- Geogrids enhance the load-bearing capacity of pavements by providing reinforcement and stabilization. They are installed within the pavement structure to distribute and limit the movement of loads, effectively increasing the pavement's strength and durability. Geogrids also help to reduce strain and prevent cracking, improving the overall performance and lifespan of the pavement.

- Q: What is the difference between Geogrid TGSG and GSL?

- GSL is the code for the two-way stretch geogrid in the standard JT/T480-2002 of the Ministry of Communications

- Q: Do geogrids provide reinforcement to geosynthetic clay liners in waste containment facilities?

- Yes, geogrids are commonly used to provide reinforcement to geosynthetic clay liners in waste containment facilities. They enhance the stability and strength of the liners, preventing them from tearing or shifting under heavy loads, and improving overall containment system performance.

- Q: What is geogrid, what is the role?

- To enhance the problemGlass fiber geogrid features:The product has the characteristics of high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long service life, can be widely used in the old cement pavement and airport runway maintenance, dams, river, slope protection, bridge pavement engineering field enhancement processing, can give the pavement reinforcement and reinforcement to prevent rutting, fatigue crack of pavement, hot and cold crack and the expansion of reflection crack, and can disperse the bearing capacity of pavement and prolong the service life of the pavement, high tensile strength and low elongation, no long-term creep, high physical and chemical stability, thermal stability, fatigue cracking, rutting resistance, cracking resistance at low temperature delay, reduce reflection crack.

- Q: How to do a good job ah? How to start the sale of geotechnical materials

- First, the product is better, the price is right, good service. Our products sell well.

- Q: Are geogrids effective in preventing soil erosion on slopes without vegetation?

- Yes, geogrids can be effective in preventing soil erosion on slopes without vegetation. Geogrids are engineered materials made from synthetic polymers, which are typically placed within the soil to reinforce it and provide stability. They help to distribute the forces acting on the soil and increase its shear strength, thus reducing the risk of erosion. However, it is important to note that geogrids alone may not be a long-term solution. It is recommended to combine them with other erosion control measures, such as hydroseeding or erosion control blankets, to achieve optimal results.

- Q: High strength geogrid reinforced cloth, steel plastic grille, PET polyester grille, PP welded geogrid, steel plastic composite tensile band, where are these geosynthetics produced?

- It has a unique performance and efficacy. Geogrid is often used as reinforcement of reinforced soil structure or composite material

Send your message to us

Woven Polyester Geogrids - PP Biaxial Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords