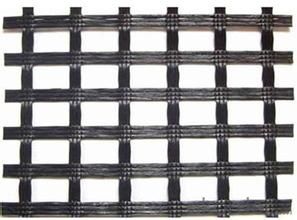

Reinforcement Geogrids - Fiberglass Geogrid Геосетк Длина Рулона Состав Пластик

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid With CE ISO certification

Геосетк Длина рулона, м 50 Разрывная нагрузка,

Intriduction:

CMAZ fiberglass georid is based on fiberglass woven cloth with modified bitumen or PVC, it was developed to address the problem of pavement cracing on highways, roads and runways, driven by a need to reduce cost for infrastructure maintanance and repair.

It is a characterized by high tensile strength in axial and lateral direcions,low stretch rate, alkali-resistance, low temperature-resistance, as well as convenience in construction and low price. It can be on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs,harbors,ports,water channels,seawalls,etc.

Performance:

High strength, high modulus and low temperatures resistance.

Product function:

1. It reinforces old asphalt concrete road surface and asphalt surface layer, and prevents damage;

2. it used for rebuilding cement concrete road surface into composite road surface and restraining reflection caused by block contraction;

3. it is used in road expansion and improvement project and crack caused by old and new combination position and uneven sedimentation;

4. it is used in soft soil base reinforcement treatment ,is favorable for soft soil water separation and concretion, restrains sedimentation effectively, distributes stress uniformly and improve overall strength of road base;

5. it is used for preventing contraction crack caused by new road semi-rigid base layer, and reinforcing and preventing road surface crack caused by foundation crack reflection

| Tensile | Warp | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 | ≥150 |

| Strength | ||||||||

| (KN) | Weft | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 | ≥150 |

| Elogation | Fiberglass | <4 % | 4 % | 4 % | 4 % | 4 % | 4 % | 4 % |

| Polyester | <13%< td=""> | 13% | 13% | 13% | 13% | 13% | 13% | |

| Mesh size(mm) | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | |

| 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | ||

| 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | ||

| 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | ||

| Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

| (Fiberglass) | ||||||||

| Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

| Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

| Temperature | Fiberglass | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

| Resistant (°C) | Polyester | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

| Resin | Fiberglass | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 |

| Content (%) | polyester | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% |

- Q: What is the difference between woven and non-woven geogrids?

- The main difference between woven and non-woven geogrids lies in their construction and composition. Woven geogrids are made by weaving tensile elements together, forming a grid-like structure. On the other hand, non-woven geogrids are created by bonding or needle-punching fibers together to form a random arrangement. Woven geogrids are typically stronger and have higher tensile strength due to their interlocking design. They are commonly used in applications that require high load-bearing capacity, such as stabilizing soil for road construction or reinforcing retaining walls. Non-woven geogrids, although less strong, offer excellent filtration and separation properties, making them suitable for erosion control, drainage systems, and preventing soil migration. In summary, woven geogrids are stronger and ideal for heavy-duty applications, while non-woven geogrids excel in filtration and separation tasks. The choice between the two depends on the specific needs of the project and the desired performance characteristics.

- Q: What is the recommended overlap distance for geogrid seams?

- The recommended overlap distance for geogrid seams varies depending on the specific application and manufacturer's guidelines. However, in general, a minimum overlap distance of 12-18 inches is often recommended to ensure proper connection and strength of the geogrid.

- Q: Can geogrids be used in mining tailings management?

- Yes, geogrids can be used in mining tailings management. Geogrids are commonly used in the mining industry to reinforce soil and stabilize slopes. In the context of tailings management, geogrids can be used to improve the stability and strength of tailings dams or containment structures, preventing erosion and potential environmental hazards. Additionally, geogrids can enhance the consolidation and dewatering of tailings, facilitating their proper management and reducing the risk of environmental contamination.

- Q: Are geogrids resistant to microbial attack?

- Yes, geogrids are typically resistant to microbial attack.

- Q: Do geogrids provide reinforcement to geosynthetic asphalt liners in reservoirs?

- No, geogrids do not provide reinforcement to geosynthetic asphalt liners in reservoirs.

- Q: Geogrid price? Solution!

- Geogrid effect1 used for roadbed reinforcement, so that the granular filler and mesh together locked together to form a stable plane, to prevent the collapse of the filler, and the vertical load can be dispersed, the geographical conditions of poor areas can be used multi-layer reinforcement;2 in the embankment and embankment fill can increase its stability, reduce the area;

- Q: Are geogrids resistant to chemical attack from soil contaminants?

- Yes, geogrids are generally resistant to chemical attack from soil contaminants.

- Q: Are geogrids suitable for use in reinforced retaining walls?

- Yes, geogrids are suitable for use in reinforced retaining walls. Geogrids are designed to provide stability and reinforcement to the soils behind retaining walls, helping to distribute the loads evenly. They enhance the overall strength and integrity of the wall, preventing soil erosion and reducing the risk of wall failure. Geogrids are commonly used in various types of retaining walls, such as gravity walls, cantilever walls, and reinforced soil walls, making them a reliable and effective solution for reinforcement.

- Q: What are the factors that affect the installation and survivability of geogrids in cold climates?

- The factors that affect the installation and survivability of geogrids in cold climates include the type and quality of geogrid material, proper preparation of the subgrade, adequate compaction of the soil, temperature variations, frost heave, snow accumulation, and freeze-thaw cycles.

- Q: Can geogrids be used in erosion control applications on steep slopes?

- Yes, geogrids can be used in erosion control applications on steep slopes. Geogrids are often employed in such situations to stabilize the soil and prevent erosion by providing reinforcement and increasing the overall strength of the slope.

Send your message to us

Reinforcement Geogrids - Fiberglass Geogrid Геосетк Длина Рулона Состав Пластик

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords