Tencate Mirafi PP Biaxial Plastic Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Geogrid:

PP biaxial plastic geogrid is manufactured from polypropylene; it is produced through the process of extruding, punching, heating, longitudinal stretching ad transverse stretching.

Applications of Geogrid:

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate static electricity, and flammability property good in the coal mine. It is easy to wash coal.

Used in highway, railway, port, airport and municipal project. Support in the recovery working face of coal mine and roadway in the coal mine.

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

Property of Geogrid:

1.) Improve roadbed bearing capacity,enlarge road lifetime.

2.) Prevent road collapse and crack

3.) Prevent soil and water loss in slope

4.) Could replace steel-plastic geogrid in coal mine.

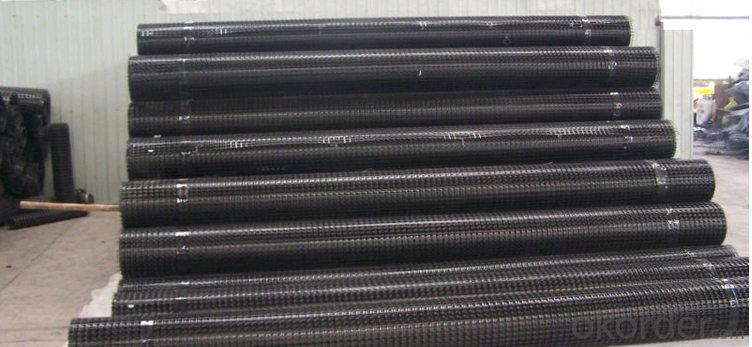

Packaging & Delivery

| Packaging Details: | Rolls in bulk, |

| Delivery Detail: | 7 days after recipt buyer's deposit |

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

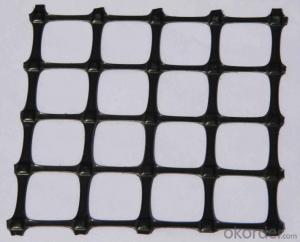

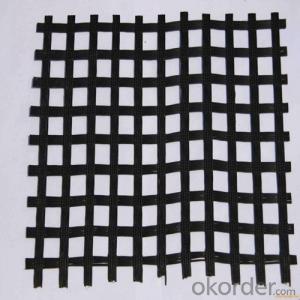

Geogrid Show:

- Q: Are geogrids resistant to UV radiation?

- Yes, geogrids are generally resistant to UV radiation. They are designed to withstand prolonged exposure to sunlight without significant degradation or loss of performance.

- Q: Geogrid standard geogrid price geogrid role

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid.

- Q: Can geogrids be used in stabilization of canal banks?

- Yes, geogrids can be used in the stabilization of canal banks. Geogrids are engineered materials that provide reinforcement and stability to soil. They can be used as a reinforcing element in the construction of canal banks to prevent erosion, improve slope stability, and increase load-bearing capacity. By distributing the forces exerted by water flow and preventing soil movement, geogrids help to maintain the integrity and stability of canal banks.

- Q: Can geogrids be used in slope stabilization for railway embankments?

- Yes, geogrids can be used in slope stabilization for railway embankments. Geogrids are commonly used in civil engineering projects to provide reinforcement and stability to soil and slopes. Their high tensile strength and ability to distribute loads make them effective in preventing slope failure and erosion. In the case of railway embankments, geogrids can be installed to improve the stability of the slopes, reduce the risk of landslides, and ensure the long-term functionality and safety of the railway infrastructure.

- Q: What is the distance between the waterproof plate and the top of the tunnel? What are the relevant provisions of this specification?

- Geotextile, composite geomembrane, bentonite waterproof blanket, a new type of three-dimensional mesh pad, geocell and other engineering materials

- Q: How do geogrids improve the performance of reinforced soil slopes in seismic areas?

- Geogrids improve the performance of reinforced soil slopes in seismic areas by providing additional stability and strength to the soil structure. They work by distributing and transferring the forces generated during an earthquake throughout the soil mass, reducing the risk of slope failure. Geogrids also enhance the overall tensile strength of the soil, preventing excessive deformation and maintaining the integrity of the slope.

- Q: What are the long-term maintenance requirements for geogrids?

- The long-term maintenance requirements for geogrids are generally minimal. Once installed properly, geogrids do not require frequent or extensive maintenance. However, periodic inspections should be conducted to ensure the geogrids are functioning effectively and to identify any potential issues such as damage or excessive soil accumulation. In case of any problems, repairs or replacements may be necessary to maintain the geogrids' performance and longevity. Overall, regular monitoring and timely interventions are crucial for ensuring the long-term effectiveness of geogrids.

- Q: Geotextiles and geogrids to do the re inspection approach?

- If necessary, geotextile and geogrid materials are qualified. But it depends on the situation.

- Q: Are geogrids resistant to chemical degradation?

- Yes, geogrids are generally resistant to chemical degradation. They are designed to withstand exposure to various chemicals commonly found in soil and water, such as acids, alkalis, and organic compounds. This chemical resistance ensures the long-term durability and performance of geogrids in different environmental conditions.

- Q: How to do this in the geogrid in the retaining wall? Is there any remedy?

- No long-term creep as reinforcing material, have in long-term load under the condition of deformation resistance that the creep resistance is extremely important, glass fiber does not creep, which ensure product can maintain long-term performance.

Send your message to us

Tencate Mirafi PP Biaxial Plastic Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords