Geogrids Noise Reduction PP Biaxial Geogrid / Fiberglass / Polyester Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

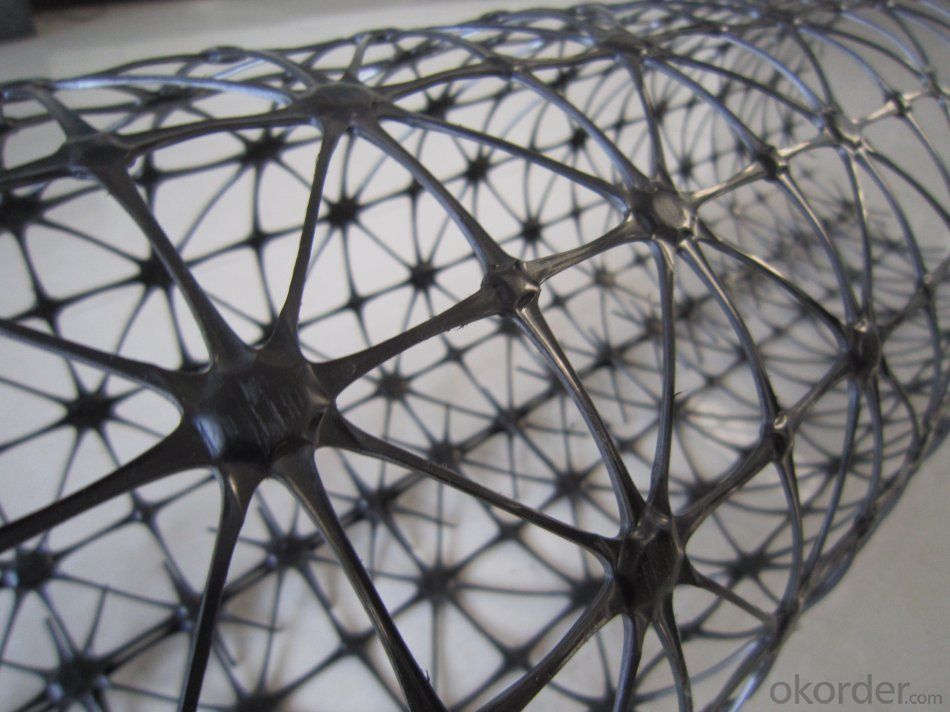

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

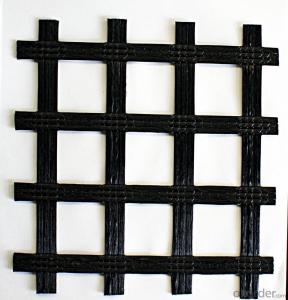

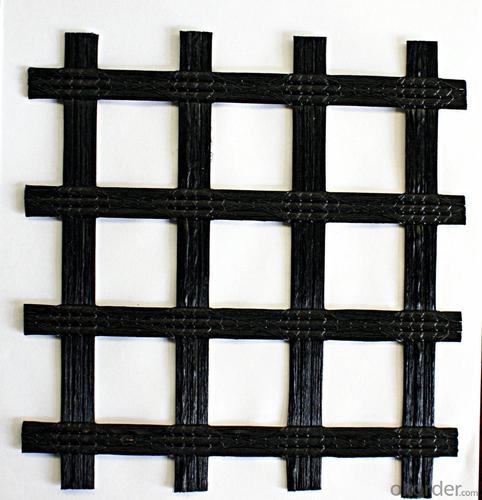

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What materials are geogrids made of?

- Geogrids are typically made from a variety of materials, including polymers such as polyester, polyethylene, and polypropylene.

- Q: Geogrid standard geogrid price geogrid role

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid.

- Q: What is the width of glass fiber grating 100cm

- Glass fiber reinforced plastic (FRP) grid is a kind of board material with a lot of space, which is made of glass fiber as reinforcing material and unsaturated polyester resin as matrix.

- Q: What are the design considerations for geogrids in reinforced soil slopes prone to seismic activity?

- Design considerations for geogrids in reinforced soil slopes prone to seismic activity include: 1. Geogrid selection: Choosing a geogrid with sufficient strength, stiffness, and durability to withstand the dynamic forces generated during seismic events is crucial. The geogrid should have high tensile strength and low elongation properties to effectively restrain the soil mass. 2. Connection details: Ensuring proper connection between the geogrid and the facing system is essential. The connection should be able to accommodate the movement and deformation of the soil during seismic events without compromising the stability of the reinforced slope. 3. Slope geometry: The slope geometry should be carefully designed to minimize the risk of failure. Factors such as slope angle, height, and overall stability need to be considered to prevent excessive stress on the geogrid and ensure it can effectively reinforce the soil. 4. Soil properties: Understanding the behavior of the soil under seismic loading is crucial for designing the geogrid reinforcement. The soil properties, such as shear strength, liquefaction potential, and settlement characteristics, should be evaluated to determine the appropriate geogrid type, spacing, and embedment depth. 5. Dynamic analysis: Conducting dynamic analysis to assess the potential response of the reinforced slope to seismic forces is important. This analysis helps in determining the required strength and stiffness of the geogrid and ensures that the slope remains stable during seismic events. 6. Construction quality control: Implementing proper construction techniques and quality control measures during geogrid installation is vital. Ensuring adequate compaction of the reinforced soil, proper connection of the geogrid to the facing system, and accurate placement of the geogrid layers are important considerations for the long-term stability of the reinforced slope in seismic-prone areas.

- Q: How do geogrids help in reducing the risk of soil liquefaction?

- Geogrids help in reducing the risk of soil liquefaction by reinforcing the soil structure and improving its stability. They act as a barrier against lateral movement of soil particles during an earthquake, thereby preventing the formation of liquefied zones. The geogrids increase the shear strength and bearing capacity of the soil, making it less susceptible to liquefaction-induced damage.

- Q: Can geogrids be used in stormwater management systems?

- Yes, geogrids can be used in stormwater management systems. Geogrids are commonly used to reinforce and stabilize soil, control erosion, and provide structural support. In stormwater management systems, geogrids can be employed to enhance the stability and strength of vegetated channels, retaining walls, and other stormwater infrastructure, improving their overall performance and longevity.

- Q: How do geogrids improve the performance of geocomposites?

- Geogrids improve the performance of geocomposites by providing reinforcement and stabilization. They enhance the load-bearing capacity and tensile strength of the geocomposite, helping to prevent soil erosion and improve overall stability. Geogrids also increase the longevity and durability of the geocomposite, making it more resistant to deformation and damage.

- Q: Can geogrids be used in temporary construction projects?

- Yes, geogrids can be used in temporary construction projects. Geogrids are often used as reinforcement materials in soil stabilization and retaining walls, providing strength and stability to the construction site. They can be easily installed and removed, making them suitable for temporary applications.

- Q: The dam is protection of geomembrane or gabion.

- There is a need to gabion can call ID

- Q: What is the recommended overlap for geogrid installation?

- The recommended overlap for geogrid installation typically varies depending on the specific project and geogrid manufacturer's recommendations. However, in most cases, a minimum overlap of 1-2 feet (30-60 centimeters) is recommended to ensure proper connection and load distribution between adjacent geogrid panels.

Send your message to us

Geogrids Noise Reduction PP Biaxial Geogrid / Fiberglass / Polyester Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords