High Strength Polyester Woven Geogrids / Biaxial Fiberglass Geogrids

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

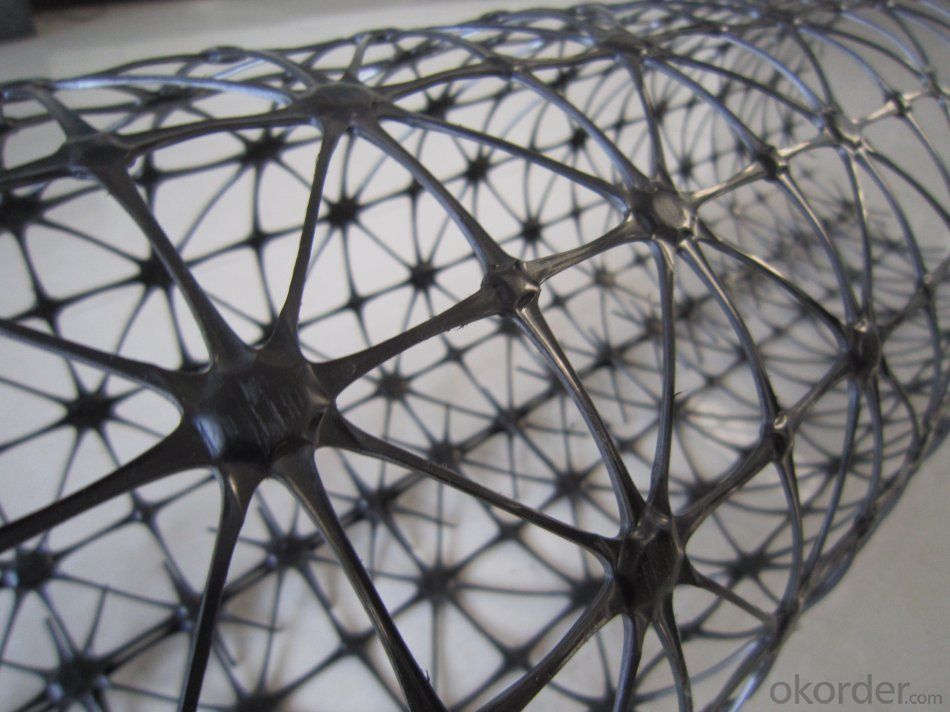

Introduction of PP Biaxial Geogrid:

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What is the recommended geogrid aperture shape for specific applications?

- The recommended geogrid aperture shape for specific applications depends on various factors such as soil type, project requirements, and installation method. It is essential to consult with geotechnical engineers or geosynthetic specialists who can analyze the specific project needs and recommend the most suitable geogrid aperture shape, which can range from square to rectangular or triangular.

- Q: What are the specifications for geogrid installation?

- The specifications for geogrid installation typically include factors such as the type and strength of the geogrid material, the required overlap or seam allowance, the recommended depth of installation, the recommended slope angle for placement, and any specific site preparation or soil compaction requirements. Other factors to consider may include the desired load-bearing capacity, the expected lifespan of the geogrid, and any additional reinforcement or anchoring methods necessary. It is important to consult the manufacturer's guidelines and any relevant engineering or construction standards for specific specifications and recommendations.

- Q: What are the factors that affect the installation of geogrids?

- There are several factors that can affect the installation of geogrids, including soil conditions, site preparation, proper placement and alignment, and proper tensioning. Soil conditions such as the type and strength of the soil, its moisture content, and any existing ground movement can impact the effectiveness of geogrids. Adequate site preparation, including clearing the area of vegetation and debris and ensuring a level base, is essential for proper installation. Proper placement and alignment of the geogrids are crucial to ensure optimal load distribution and stability. Additionally, geogrids need to be properly tensioned to achieve the desired reinforcement and soil stabilization.

- Q: Are geogrids effective in stabilizing dredged material containment areas?

- Yes, geogrids are effective in stabilizing dredged material containment areas. They provide reinforcement and stability to the soil, preventing erosion and maintaining the integrity of the containment area. Geogrids are specifically designed to distribute and manage loads, improving the overall performance and long-term stability of dredged material containment areas.

- Q: What is high strength geogrid

- Like fiberglass 150KN polyester 180KN unidirectional plastic 200KN

- Q: How are geogrids installed in the field?

- Geogrids are typically installed in the field by first preparing the subgrade by removing any vegetation or loose soil. The geogrid is then rolled out and placed on top of the subgrade, ensuring it is properly aligned and covers the desired area. It is then secured in place using stakes, pins, or other anchoring methods. Finally, the geogrid is covered with a layer of fill material, such as soil or gravel, which is compacted to provide additional stability and load-bearing capacity.

- Q: What are the advantages of using geogrids in ground improvement for settlement control?

- Geogrids offer several advantages in ground improvement for settlement control. Firstly, they provide increased soil stability by distributing loads more evenly, thereby reducing settlement and preventing soil erosion. Secondly, geogrids enhance soil reinforcement, increasing the bearing capacity of the ground and allowing for the construction of heavier structures. Additionally, these materials are easy to install and cost-effective, saving time and money during the ground improvement process. Overall, geogrids offer a reliable and efficient solution for settlement control and improved ground stability.

- Q: What are the differences between geogrids and geosynthetic clay liners?

- Geogrids and geosynthetic clay liners (GCLs) are both geosynthetic materials used in geotechnical applications, but they have distinct differences. Geogrids are typically made from high-strength polymers, such as polypropylene or polyester, and have a grid-like structure. They are used to reinforce soil, providing tensile strength and preventing soil erosion. Geogrids are commonly used in road construction, retaining walls, and slope stabilization projects. On the other hand, geosynthetic clay liners (GCLs) consist of a layer of bentonite clay sandwiched between two geotextiles. The clay component of GCLs gives them excellent hydraulic barrier properties, making them highly effective in containment applications. GCLs are commonly used in landfills, mining sites, and other projects that require the containment of liquids or gases. In summary, while geogrids reinforce soil and provide tensile strength, geosynthetic clay liners act as hydraulic barriers and are used for containment purposes.

- Q: What type of geogrid is CATTXDJ?

- The geogrid grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid

- Q: What is the principle of geogrid?

- What is the steel plastic composite geogrid [2]: steel plastic composite geogrid by high strength steel wire by high density polyethylene wrapped into high strength strip, press flat weft at right angles to the welding of geosynthetic materials formed by ultrasonic, according to the needs of the engineering with different mesh diameter and steel wires to change the reinforcement force.

Send your message to us

High Strength Polyester Woven Geogrids / Biaxial Fiberglass Geogrids

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords