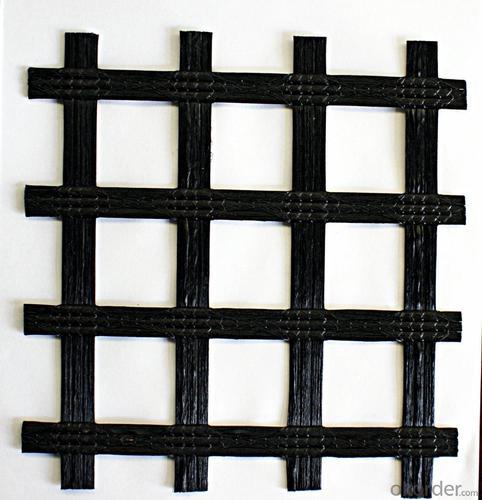

Egrid App Biaxial Geogrids - Polyester, PP, Fiberglass

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Introduction of Fiberglass Geogrid:

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life.

It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

1) High strength 2) High modulus 3) Low temperatures resistance.

2. Performance of Fiberglass Geogrid:

3. Applications of Fiberglass Geogrid:

--- Road pavement

--- Railway basement

--- Tunnel

--- Slope

--- Embankment.

4. Fiberglass Geogrid Features:

1.Intensity of vertically and horizontally from 20 KN/M to 150 KN/M

2.Low breaking elongation, not bigger than 3%

3.Suitable for each kind of soil environment

4.For treatment on surface, the rib suppresses the rough pattern, strengthens the grill surface the rough degree, enhances the GSZ steel plastic complex geogrid in the soil body friction factor.

5.It has more superior breadth, up to 2- 6 m, reducing construction joining, enhances the work efficiency.

6.High intensity, low creep and distorting

7.Resistant to erosion, longer life.

8.Easy and convenient to install, short period and low cost- saving. It can save project cost by 10%- 50%.

FAQ:

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q: Reinforced soil technology is embedded in the soil of geosynthetics, which in the soil into the steel line?

- The concept of reinforcement is very old.This is the oldest now can see Dujiangyan water if can find the concept of reinforcement.

- Q: How do geogrids improve the performance of asphalt pavements?

- Geogrids improve the performance of asphalt pavements by providing reinforcement and stabilization. They enhance the tensile strength of the pavement, preventing cracking and rutting caused by traffic loads. Additionally, geogrids reduce reflective cracking by distributing the stress from underlying layers, improving the overall structural integrity and lifespan of the pavement.

- Q: How much is the horizontal overlap length of the steel plastic geogrid

- The double lap length is 50cm, and the steel nails. Geotextile lap length is 50cm to 1m

- Q: Are geogrids resistant to microbial attack?

- Yes, geogrids are typically resistant to microbial attack.

- Q: Are geogrids resistant to biological degradation?

- Yes, geogrids are generally resistant to biological degradation. They are typically made from synthetic materials such as polypropylene or polyester, which are not easily biodegradable. This makes geogrids a durable and long-lasting solution for reinforcement and stabilization applications where exposure to biological factors is a concern.

- Q: Technical specifications of glass fiber grating

- Specification EGA1 * 1A-N EGA1 * 1CA-N EGA1 * 2A-N EGA2 * 2C-N EGA1 * 1A EGA1 * 1CA EGA1 * 1B EGA2 * 2A EGA2 * 2CA * 2B fracture strength of EGA1 * EGA2 * EGA2 * 2B-N * 1B-N * 1C * EGA2 *

- Q: Details of fiberglass geogrid

- 3, high temperature rutThe asphalt concrete has rheological properties at high temperature, specific performance in summer: asphalt road surface soft and sticky; under the vehicle load, the stress area from depression, vehicle load after the removal of the asphalt surface layer cannot be completely restored to the loading condition before, which produce plastic deformation in the vehicle repeatedly; under the action of rolling plastic deformation accumulation, rutting. We analyze the asphalt pavement structure, because of high temperature asphalt concrete with rheology, while under load, without any constraint mechanism can aggregate movement of the asphalt concrete surface layer, resulting in asphalt surface layer goes on, this is the main reason of the formation of rutting.The fiberglass geogrid is used in the asphalt overlay, which plays the role of skeleton in the asphalt surface layer. The asphalt concrete aggregate throughout the grid, to form a composite mechanical interlocking system, limit the aggregate movement, increase the lateral cover surface layer in asphalt binding, each part of the asphalt layer in each other, to prevent the asphalt surface layer goes on, which plays the role of rutting resistance.

- Q: What is the difference between Geogrid TGSG and GSL?

- TGSG is the national standard GB/T17689-2008 double plastic geogrid code

- Q: What are the technical parameters and testing standards of the tensile creep testing machine

- Tensile creep testing machine for the determination of tensile creep and tensile fracture properties of Geotextiles and geotextile.

- Q: How do geogrids prevent differential settlement?

- Geogrids prevent differential settlement by distributing the load and enhancing the stability of soil by providing reinforcement. They improve the overall strength and stiffness of the soil, reducing the likelihood of differential settlement occurring.

Send your message to us

Egrid App Biaxial Geogrids - Polyester, PP, Fiberglass

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords