High Strength Biaxial Geogrids / PP Uniaxial Geogrid / Fiberglass Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

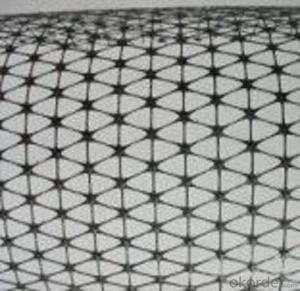

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life.

Performance of Fiberglass Geogrid:

--- High strength, high modulus and low temperatures resistance.

Applications of Fiberglass Geogrid:

--- Reinforcement for road pavement

--- Reinforcement for railway basement

--- Reinforcement for Tunnel

--- Reinforcement for Slope

--- Reinforcement for embankment.

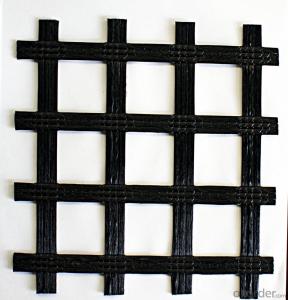

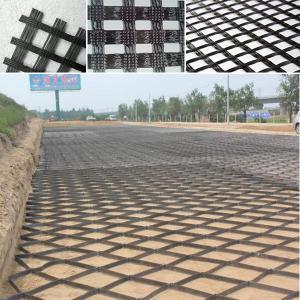

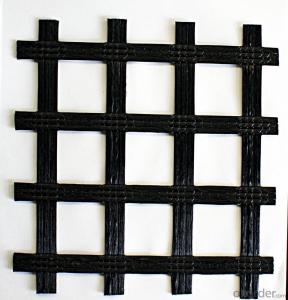

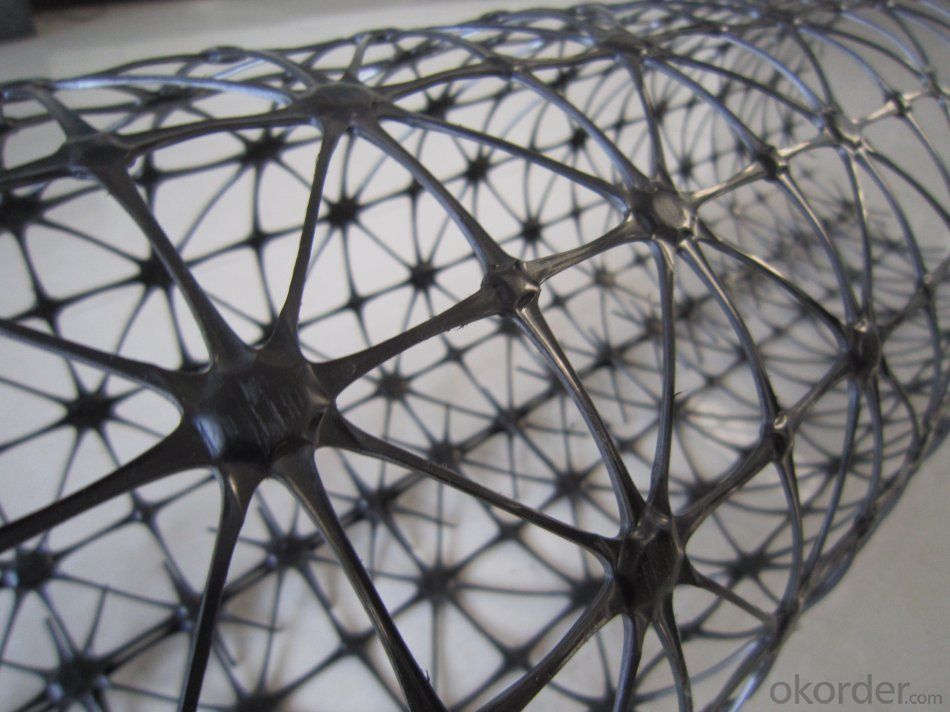

Introduction of PP Biaxial Geogrid:

Biaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in longitudinal and transverse directions.

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

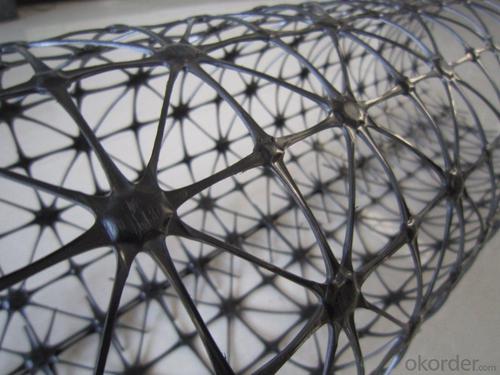

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What is the effect of soil type on geogrid performance?

- The effect of soil type on geogrid performance can vary. Different soil types have varying levels of strength, compaction, and drainage capabilities, which can impact the ability of the geogrid to properly reinforce the soil. For example, cohesive soils with high clay content may cause the geogrid to experience reduced tensile strength and limited interlocking capability. On the other hand, granular soils with good drainage properties may enhance the geogrid's performance by allowing better load distribution. Therefore, understanding the soil type is crucial in determining the suitability and effectiveness of geogrid installation for soil reinforcement.

- Q: What is the coefficient of friction of Nonwoven Geotextiles (polypropylene)?

- Generally, geomembrane is used in Seepage Control Engineering

- Q: How to distinguish from the appearance of plastic geogrid and fiberglass geogrid

- Fundamentally different things.。

- Q: What are the different materials used to manufacture geogrids?

- Geogrids are manufactured using various materials such as polyester, polypropylene, high-density polyethylene (HDPE), and fiberglass. These materials offer different strengths, durability, and chemical resistances, allowing geogrids to be customized for various applications in civil engineering and construction projects.

- Q: Are geogrids effective in stabilizing dredged material containment areas?

- Yes, geogrids are effective in stabilizing dredged material containment areas. They provide reinforcement and stability to the soil, preventing erosion and maintaining the integrity of the containment area. Geogrids are specifically designed to distribute and manage loads, improving the overall performance and long-term stability of dredged material containment areas.

- Q: What is the road geogrid

- GeogridThe grid is made of polypropylene, polyvinyl chloride and other high molecular polymer thermoplastic or molded into a two-dimensional grid or a certain degree of three-dimensional grid screen, when used as civil engineering, known as the geogrid

- Q: What are the factors to consider when selecting geogrids for a project?

- When selecting geogrids for a project, there are several factors to consider. These include the specific application or purpose of the project, the site conditions such as soil type and slope stability, the load requirements of the project, the desired lifespan and durability of the geogrids, and the cost-effectiveness and availability of the geogrids. Additionally, it is important to consider the installation process and compatibility with other materials used in the project. By considering these factors, you can ensure that the selected geogrids will effectively meet the needs of your project.

- Q: How do geogrids help in the construction of embankments?

- Geogrids help in the construction of embankments by providing reinforcement and stability to the soil. They are placed within the embankment to distribute the load and prevent soil movement. Geogrids also enhance the overall strength of the embankment, reducing the risk of settlement and erosion.

- Q: What is the difference between plastic geogrid and grid

- It's not the same thing

- Q: How to determine the number of geogrid detection method

- In the finished product cut at least 1 meters of the length of the geogrid, the radial shear of the 3, the zonal shear of the 3, and then tested, take its average value can be.

Send your message to us

High Strength Biaxial Geogrids / PP Uniaxial Geogrid / Fiberglass Geogrid

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords