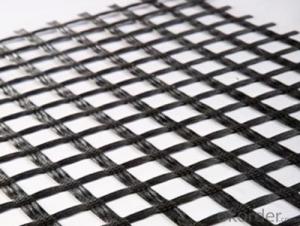

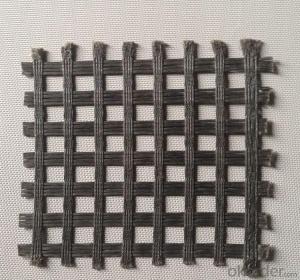

Woven Geogrids - High Tensile Strength Pet Geogrid Customizable

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

High tensile strength at low elongation

Low tendency to creep

Optimized grid structure

PET Geogrid 30-1200kN/m

Bitumen / PVC

PET geogrid for road,slope,airport,retaining wall,breakwater,marine and soil reinforcement 30-1200kN/m

Basic Info:

Grid® geogrid is made of filament yarn with high strength, high modulus and low creep deformation through advanced coating technology. Grid is 3m—6m wide and 100m—300m long,and can reduce the connecting rate.

The tension force of Grid® geogrid ranges from 200KN/m—1200KN/m, and we can provide geogrid with tension force ranging from 800KN to 1200KN for special projects and partially reinforced geogrid,composite geogrid and other kinds of geogrid according to project requirements.

Geosynthetics have been an essential material for projects , like highway, railway, airport road, bridge, tunnel and culvert

Grid® geogrid has a better ecomomic efficiency and enviromental effect and it is simple, agile, safe and efficient to use.

Feature:

The warp knitting polyester geogrid has high intensity. The high module, the high module,the low slow change. The anti-aging,the anti-embrittlement,the tensile strength to be high strength,the anti-peel strength is big .

Application:

1.Reinforced soil engineering(reinforced soil retaining wall, steep slope and the reinforcement and consolidation of the soft ground);

2.Road construction(ground treatment, reinforcement of the bridge abutment, reinforcement of the enbankment, reinforcement of the pile-net roadbed)

3. Irrigation projects(protection of port, approach lane, seabeach, channel, river channel, dam and other irrigation projects.)

4. Enviromental projects(land reclamation, prevention and controlling of the desertification,and the composite protective structure in the landfill sites of urban garbage and waste)

5. Mine engineering(coal mines, side slope protection of opencast mines, slope protection for the dumping site of the opencast mines,reinforcement to counter dam in the large tailing ponds of the metallurgical mines)

6. Construction of stuffing and package system of heavy soil engineering

7. slope protection in the area affected by earthquake

8. Ground consolidation of large dump leaching sites and slag site.

Packing and Delivery

| Packaging Details: | PE film |

| Delivery Detail: | within 10 days after contract is effective |

Geogrid Show:

FAQ:

1. How to order your geogrid ?

a). Tensile strength in warp & weft direction

b). Grid size

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

c) cash

d) 30% contact value as deposit ,the blance 70% be paid after received the copy of bl .

3. Delivery time

a) 19-25 days after received your depsit .

4. What is MQQ ?

a) 2500 m2 as MQQ , we can also produce sample for you .

- Q: What is the role of Geogrid

- Paving the role of geogrid:1, geogrid used to increase the road (ground) bearing capacity of the foundation, Yan Changlu (ground) based service life.2, geogrid used to prevent the road (ground) surface collapse or crack, keep the ground beautiful and tidy.

- Q: Geogrid has a bundle of multiple

- Hello: Geogrid according to different material, width and length are not the same, the tension requirements are not the same, the tension weight is high, volume weight is high, so a roll weight is not the same, generally 2 meters wide, 100 meters long

- Q: What are the factors that affect the installation of geogrids?

- There are several factors that can affect the installation of geogrids, including soil conditions, site preparation, proper placement and alignment, and proper tensioning. Soil conditions such as the type and strength of the soil, its moisture content, and any existing ground movement can impact the effectiveness of geogrids. Adequate site preparation, including clearing the area of vegetation and debris and ensuring a level base, is essential for proper installation. Proper placement and alignment of the geogrids are crucial to ensure optimal load distribution and stability. Additionally, geogrids need to be properly tensioned to achieve the desired reinforcement and soil stabilization.

- Q: Are geogrids suitable for use in reinforced soil slopes?

- Yes, geogrids are suitable for use in reinforced soil slopes. Geogrids are commonly used to enhance the stability and strength of soil slopes by providing reinforcement and preventing soil erosion. They are designed to distribute load and improve the overall performance of the slope, making them an effective solution for reinforced soil slopes.

- Q: Why steel plastic geogrid in the test, will choose to peel out a single wire test? What are the causes and sources of this method?

- Peel out because of the more intuitive understanding of the strength of the tensile strength and extension of the length of the wire wrapped in order to protect the steel wire does not rust.

- Q: I would like to ask the geotechnical engineering of highway engineering, geogrid raw materials for the conventional test items, parameters?

- The mechanical properties (including Strip Tensile test, joint / joint width tensile test, solder stick limit peel strength test); sampling frequency: each batch of incoming inspection time, quantity of each test group representing more than 500 volumes

- Q: What is the number of tensile elements of Geotextiles

- The tensile unit number of geotextiles: the strength of the geotextile under the action of a certain width of 1 meters. KN/m

- Q: Can geogrids be used in stormwater management systems?

- Yes, geogrids can be used in stormwater management systems. Geogrids are often utilized to reinforce and stabilize soil in stormwater management applications such as retaining walls, embankments, and erosion control measures. They can help improve the overall performance and longevity of stormwater management structures by enhancing soil stability and preventing erosion.

- Q: How do geogrids improve soil stabilization?

- Geogrids improve soil stabilization by providing reinforcement and enhancing the tensile strength of the soil. They create a stable interlocking structure within the soil, preventing it from shifting or eroding under heavy loads or environmental factors such as rainfall or wind. Geogrids also distribute the load more evenly, reducing the pressure on the soil and preventing settlement. Overall, geogrids help to enhance the stability and durability of soil in various construction and civil engineering applications.

- Q: What are the advantages of using geogrids in ground improvement for slope stabilization?

- Geogrids offer several advantages when used in ground improvement for slope stabilization. Firstly, they enhance the tensile strength of the soil, providing reinforcement against slope movement and potential failure. Secondly, geogrids distribute the load more evenly, reducing stress concentrations and preventing localized failures. Additionally, these materials are easy to install and cost-effective, making them a practical solution for stabilizing slopes. They also allow for better drainage, reducing the risk of water accumulation and associated erosion. Overall, geogrids provide a reliable and efficient method for enhancing slope stability and reducing the risk of slope failure.

Send your message to us

Woven Geogrids - High Tensile Strength Pet Geogrid Customizable

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords