Geocells for Driveways - Biaxial Steel Plastic Geogrids for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Jiangsu, China (Mainland)

Brand Name:

Lonrace

Model Number:

geogrid

Material:

Polyester

Color:

White Black Gray Etc

Tensile strength:

25Kn/m--300Kn/m

Length:

50-100m

Certification:

CE /ISO9001

Coating:

PVC

Product Introduction

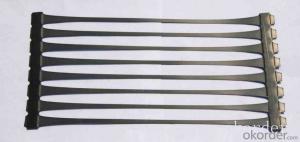

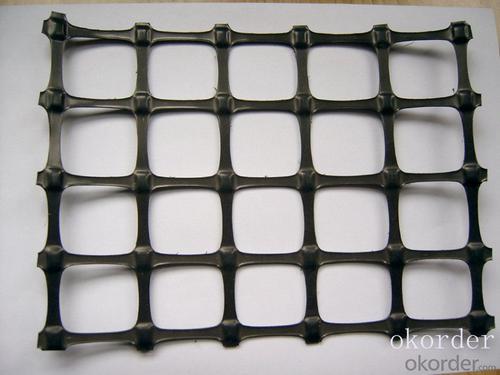

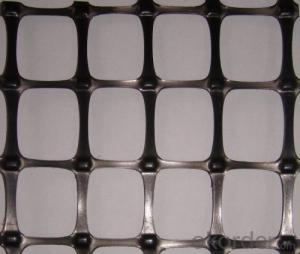

The Steel plastic composite geogrid is by the high tensile steel wire, after the special handing, with the polyethylene(P. E), and increase other assistants, though squeezes out causes it excel to become the mult-skill anti-to pull the banding, and the surface has the rough embossing, for excel in reinforcement earthwork belt. From this as soon as the single belt, after vertical, according to decides the spacing knitting horizontally or clamps gathers the arrangement, uses the ultrasonic welding to molding.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

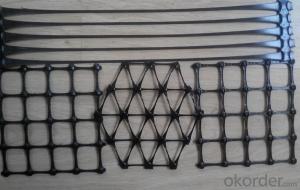

A: Yes, please check the pictures:

- Q: What are the potential drawbacks of using geogrids?

- Some potential drawbacks of using geogrids include their high cost compared to other soil stabilization methods, the need for proper installation and maintenance to ensure effectiveness, and limitations in their ability to withstand certain extreme environmental conditions such as high temperatures or chemical exposure. Additionally, geogrids may not be suitable for all soil types or site conditions, requiring a thorough analysis and consideration of alternative solutions.

- Q: Which is the most suitable for Highway Subgrade

- We are specializing in the production of geogrid. The words are basically according to design drawings, but if you use it, most or two-way plastic and steel grating, durable plastic relatively longer, of course, the price is higher; two-way plastic instead.

- Q: Product features: high strength, small deformation; creep; corrosion resistance, long service life: steel plastic geogrid with plastic material as a protective layer, which is supplemented with a variety of additives in aging resistance, oxidation resistance, corrosion resistance to acid and alkali, salt and other harsh environment

- Normal should read Zha, but because of the dialect or engineering terminology habits, read Shan, habit, this is just a personal idea.

- Q: Is there a big difference between horizontal permeability and vertical permeability coefficient

- . That is to say, the permeability coefficient of geosynthetics is broad. The vertical permeability coefficient is unique to geotextiles. The test methods of permeability coefficient and vertical permeability coefficient are similar.

- Q: Can geogrids be used in erosion control on slopes and hillsides?

- Yes, geogrids can be used effectively in erosion control on slopes and hillsides. Geogrids are commonly used to reinforce soil and provide stability, preventing erosion and soil movement. They help to distribute loads and enhance the strength of the soil, reducing the risk of erosion on slopes and hillsides.

- Q: How much is the steel plastic geogrid?

- The steel plastic geogrid is also called the steel plastic grille, the steel plastic composite geogrid, a lot of also called the plastic steel grille (a kind of misreading), is a kind of geogrid. The price of steel plastic geogrid is divided according to the model, the model of steel plastic geogrid has 30KN, 40KN, 50KN, 60KN, 70KN, and so on, the maximum can reach 150KN. Commonly used models of steel plastic geogrid prices are as follows:

- Q: What is the difference between plastic geogrid and grid

- It's not the same thing

- Q: Can geogrids be used in reinforcement of underground storage tanks?

- Yes, geogrids can be used in the reinforcement of underground storage tanks. Geogrids are commonly used in civil engineering applications to improve the stability and load-bearing capacity of soil structures. When used in the reinforcement of underground storage tanks, geogrids help distribute the load more evenly, reduce stress on the tank walls, and increase the overall strength and stability of the tank system.

- Q: How much is the overlap length of Geogrid

- The horizontal distribution of shear walls should be staggered staggered 500mm, lap length 1.2LaE.

- Q: What is the market price of the geotechnical grid in 2017?

- 5) as the second layer of geogrid layer construction method with the first method, and finally filling in 0.3m (coarse sand), filling in the same way as the first layer, using 25T hydrostatic roller two times, so subgrade reinforcement is dealt with. (6) in the third layer (coarse sand) after rolling, along the line in the longitudinal slope on both sides of the geogrid two, overlapping 0.16m, and connected with the same method, and then start the earthwork construction work, laying geogrid in slope protection, each layer must measure the laying of lines, each side to ensure the slope renovation of geogrid buried in slope soil 0.10m. (7) when the geogrid is filled with two layers of soil, that is to say, the thickness of the 0.8m is to be provided with a layer of geogrid at the same time, and then, and so on, until the supply of the market price to the surface of the shoulder table Datong geogrid. Datong geogrid products? Datong geogrid supply market price is how much? Datong geogrid. Datong geogrid products? Datong geogrid supply market price is how much? Datong geogrid. Datong geogrid products? Datong geogrid. (8) the Subgrade after timely slope renovation, and dry rubble slope protection, in addition to each side of the roadbed widening 0.3m, and set aside 1.5% of the settlement.

Send your message to us

Geocells for Driveways - Biaxial Steel Plastic Geogrids for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords