Geocells and Geogrids - High Quality Bitumen Coated Black Fiberglass Geogrid (30KN*30KN-200KN*120KN) for Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

1.Introduction of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

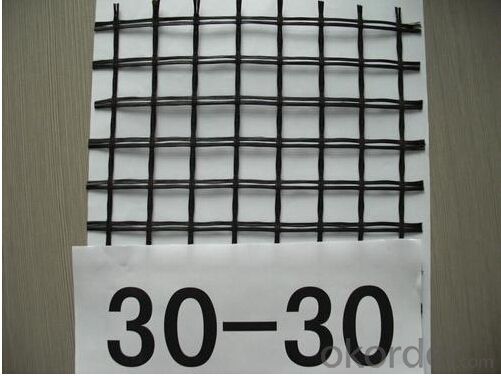

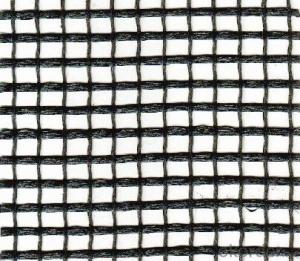

Fiberglass geogrid is a kind of plane network shape material that selects excellent reinforcement non-alkali fiberglass yarn. It is weaven into base material by using foreign advanced warp knitter and adopts warp knitted directional structure. It makes full use of yarn strength in textile, improves its chemical performance and makes it have good tention resistance, tearing resistance and creep resistance and is formed by excellent modified asphalt coating treatment. It follows similar and compatible principle, lays stress on its synthetic performance with asphalt mixture, protects glass fiber base material fully and improve wearing resistance and shearing force resistance of base material so as to make road surface reinforce, to prevent highway harm such as crack and rut from occuring and to solve the problem that asphalt road surface is difficult for reinforcement.

2.Properties of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

The product has high intensity, low elongation ratio, thermostable, high module, light weight, good toughness, anticorrosive, long life and so on characteristics.

It can be applied in the old cement road surface, runway’s service, the dike, the river bank, the side protection, project domains and so on road bridge connection surface enhancement processing.

It can reinforce the road surface and prevents the road surface rut fatigue cracking the hot-cold expansion crack and the following reflection crack.

It can scatter the road surface bearing stress, extense road surface service life, the high tensile strength and the low elongation ratio, no long-term slow change. The physical chemistry stability are good anti-weary dehiscence, antilow temperature shrinkage crack and postpone reduction reflection crack.

3.Specification and Technical Data of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

The parameters of fiberglass geogrid | |||||||

classification | Model number | Break Intensity (KN/m) | Break elongation ratio (%) | Mesh size (mm×mm) | Breadth (m) | ||

longitudinal | horizontal | longitudinal | horizontal | ||||

Fiberglass geogrid | GG2525 | ≥25 | ≥25 | ≤3 | ≤3 | 12~50 | 1~6 |

GG3030 | ≥30 | ≥30 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG4040 | ≥40 | ≥40 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG5050 | ≥50 | ≥50 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG8080 | ≥80 | ≥80 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG100100 | ≥100 | ≥100 | ≤3 | ≤3 | 12~50 | 1~6 | |

GG120120 | ≥120 | ≥120 | ≤3 | ≤3 | 12~50 | 1~6 | |

Self—adhesive fiberglass geogrid | GGA2525 | ≥25 | ≥25 | ≤3 | ≤3 | 12~50 | 1~6 |

GGA3030 | ≥30 | ≥30 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA4040 | ≥40 | ≥40 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA5050 | ≥50 | ≥50 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA8080 | ≥80 | ≥80 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA100100 | ≥100 | ≥100 | ≤3 | ≤3 | 12~50 | 1~6 | |

GGA120120 | ≥120 | ≥120 | ≤3 | ≤3 | 12~50 | ||

4.Application and Technical Data of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

Reinforcement for road pavement

Reinforcement for railway basement

Reinforcement for tunnel

Reinforcement for slope

Reinforcement for embankment

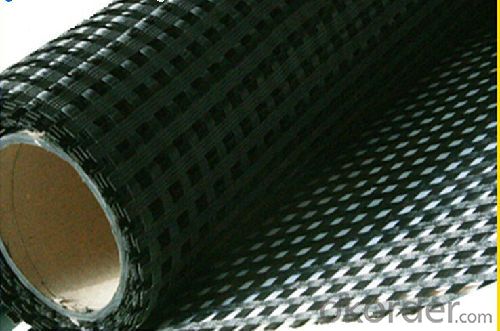

5.Product Photos and Technical Data of High Quality Bitumen Coated (30KN*30KN-200KN*120KN) Black Fiberglass Geogrid for Road Construction

- Q: Can geogrids be used in underground mining operations?

- Yes, geogrids can be used in underground mining operations. They are a type of geosynthetic material that can provide reinforcement and stabilization to the ground, helping to prevent soil erosion, improve load-bearing capacity, and enhance overall safety in mining tunnels and excavations.

- Q: Production of geotextile manufacturers which good

- Needle punched nonwoven fabric and PE film composite geotextile:A specification film cloth, a cloth film two, maximum width of 4.2 meters is the main raw material to use acupuncture non-woven polyester staple fiber, PE film by composite, is mainly used for seepage control, applicable to rail, highway, tunnel, subway, airport project. Geotextile manufacturers can choose Wo environmental protection

- Q: Can geogrids be used in slope stabilization for mining waste dumps?

- Yes, geogrids can be used in slope stabilization for mining waste dumps. Geogrids are commonly used in civil engineering projects to reinforce and stabilize slopes. By incorporating geogrids into the design and construction of mining waste dumps, the stability of the slopes can be improved, preventing potential slope failures and reducing the risk of environmental hazards.

- Q: Are geogrids effective in erosion control?

- Yes, geogrids are effective in erosion control. They provide stabilization and reinforcement to soil, preventing erosion by holding it in place and distributing loads. Geogrids also improve the overall strength of the soil, making them an effective solution for erosion control in various applications such as slopes, retaining walls, and road construction.

- Q: What is the significance of each index

- Geosynthetics shall comply with the following requirements:One)The bearing layer should be smooth, paving should be straightened, smooth, close to the underlying layer, shall not distort, wrinkle. In the obliqueThe slope on shop, should maintain a certain degree of tightness.

- Q: Can geogrids be used in reinforcement of coastal structures?

- Yes, geogrids can be used in the reinforcement of coastal structures. Geogrids are a type of geosynthetic material that can provide stability and strength to soil and other materials. When used in coastal structures such as seawalls or revetments, geogrids can help to prevent erosion, improve stability, and enhance the overall structural integrity of the coastal defenses.

- Q: Can geogrids be used in soil stabilization for parking lots?

- Yes, geogrids can be used in soil stabilization for parking lots. Geogrids are strong and flexible materials that can be placed beneath the surface of the parking lot to improve the load-bearing capacity of the soil, reduce soil erosion, and increase the overall stability of the parking lot. By distributing the weight of vehicles more evenly, geogrids help to prevent rutting, cracking, and other damages that can occur due to heavy traffic and poor soil conditions.

- Q: What are the maintenance requirements for geogrid-reinforced structures?

- The maintenance requirements for geogrid-reinforced structures typically involve regular inspections to check for any signs of damage or degradation. This includes assessing the condition of the geogrid, ensuring proper connection between the geogrid and the surrounding materials, and monitoring any settlement or movement of the structure. Additionally, vegetation management is important to prevent root intrusion which can compromise the integrity of the geogrid. Regular cleaning and clearing of debris is also necessary to maintain the functionality and lifespan of geogrid-reinforced structures.

- Q: How do geogrids help in the construction of embankments?

- Geogrids help in the construction of embankments by providing reinforcement and stability to the soil. They are placed within the embankment to distribute the load and prevent soil movement. Geogrids also enhance the overall strength of the embankment, reducing the risk of settlement and erosion.

- Q: What are the applications of geogrids?

- Geogrids have various applications in civil engineering and construction projects. They are commonly used for soil stabilization, reinforcement of retaining walls and slopes, erosion control, and pavement reinforcement. Geogrids provide strength and stability to the soil, prevent soil movement, and improve the overall structural integrity of the project.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Geocells and Geogrids - High Quality Bitumen Coated Black Fiberglass Geogrid (30KN*30KN-200KN*120KN) for Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords