Geogrids for Velocity Slopes - Fiberglass Geogrid 120KN for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid 120KN for Road Construction

Description Of Fiberglass Geogrid 120KN for Road Construction:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid 120KN for Road Construction:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid 120KN for Road Construction:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid 120KN for Road Construction:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

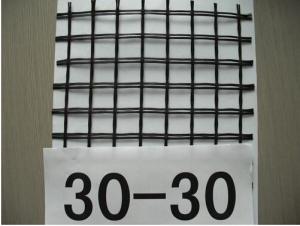

IMages of Fiberglass Geogrid 120KN for Road Construction:

FAQ of Fiberglass Geogrid 120KN for Road Construction:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geogrids improve the stability of levees?

- Geogrids improve the stability of levees by providing reinforcement to the soil structure. They are designed to distribute the forces exerted by the soil and help prevent erosion and slope failure. Geogrids act as a stabilizing mechanism by increasing the strength of the levee, reducing the potential for settlement, and enhancing its overall stability.

- Q: 300 grams of geotextiles a square meter

- Geotextile is a kind of new material geosynthetics, the product is cloth, the general width of 4-6 meters, the length of 50-100 M. Geotextiles are divided into nonwoven geotextiles and nonwoven geotextiles.Ordinary 2 or so

- Q: History of geotechnical materials

- Geosynthetics are widely used in geotechnical engineering at present, which is a general name of polymer products. As early as in 1920s, the chemical industry was successful in the production of synthetic materials, but it was not until the late 50s that the material was gradually used as a new type of building materials to be used in geotechnical engineering. In the early stage, the products were mainly pervious to spinning and non-woven geotextiles, and later produced impermeable geomembrane. With the requirement of engineering practice and the improvement of manufacturing technology, the geogrid and other composite products with high strength reinforcement are manufactured. In this way, the original geotechnical fabric word has not summarized all kinds of products in the international meaning, so there are many alternative names, the geotextile material was the most common, but the habit still referred to as geotextile. Geotechnical material is divided into several categories of materials: geotextile, geomembrane, geogrid, drainage board, composite geomembrane, geotextile, geocell, bentonite waterproof blanket, etc..

- Q: What are the factors that affect the long-term creep behavior of geogrids?

- The factors that affect the long-term creep behavior of geogrids include the type and quality of the material used in the geogrid, the load applied to the geogrid, the environmental conditions in which the geogrid is placed, and the duration of the load application. Additionally, factors such as installation technique, strain rate, and the presence of moisture can also influence the long-term creep behavior of geogrids.

- Q: Can geogrids be used in underground tunnels?

- Yes, geogrids can be used in underground tunnels. Geogrids are commonly used in tunnel construction to reinforce the surrounding soil or rock, providing additional stability and reducing the risk of ground movement. They help distribute the loads and prevent soil or rock collapse, ensuring the safety and longevity of the tunnel structure.

- Q: Are geogrids resistant to high temperatures?

- Yes, geogrids are typically resistant to high temperatures. They are designed to withstand extreme weather conditions, including high temperatures, without significant degradation or loss of performance.

- Q: Can geogrids be used in ground reinforcement for military installations?

- Yes, geogrids can be used in ground reinforcement for military installations. Geogrids are often employed in various civil engineering applications, including military projects, to enhance soil stability, provide load-bearing support, and improve overall ground reinforcement. They are effective in reinforcing and stabilizing soil, which is essential for military installations that require durable and resilient foundations to withstand heavy equipment, traffic, and potential ground disturbances. Geogrids can also assist in reducing soil erosion, enhancing slope stability, and minimizing the risk of ground movement or settlement, making them a valuable tool in military construction and infrastructure projects.

- Q: What is the typical lifespan of geogrids?

- The typical lifespan of geogrids can vary depending on factors such as the quality of the material, the environmental conditions they are exposed to, and the level of stress they experience. However, geogrids are generally designed to have a lifespan of 20 to 50 years.

- Q: What are the differences between geogrids and geotubes?

- Geogrids and geotubes are both used in geotechnical engineering, but they serve different purposes. Geogrids are typically used for soil stabilization and reinforcement, where they are placed within the soil to distribute loads and improve the overall strength of the structure. On the other hand, geotubes are large, cylindrical containers made of geotextile fabric, filled with sand or other materials, and used for shoreline protection, erosion control, and dewatering. While both geogrids and geotubes are beneficial in their respective applications, their differences lie in their form, function, and the specific challenges they address.

- Q: What are the factors affecting the durability of geogrids?

- The factors affecting the durability of geogrids include the quality of materials used in manufacturing, the level of UV resistance, the ability to withstand chemical exposure, the design and construction of the geogrid, and the conditions and environment in which it is installed.

Send your message to us

Geogrids for Velocity Slopes - Fiberglass Geogrid 120KN for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords