Tenax Biaxial Geogrids - Bitumen Coated Fiberglass Geogrid 100~100/kn for Roadbed Reinforce

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

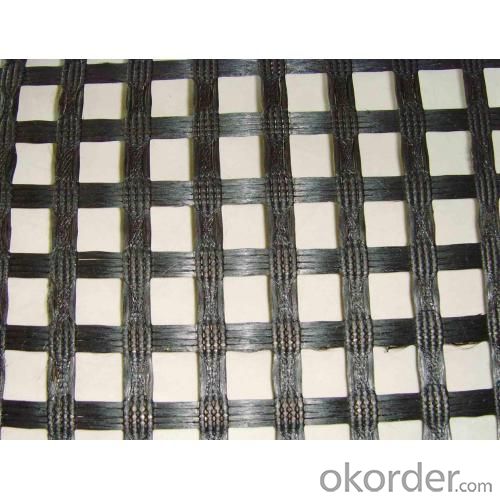

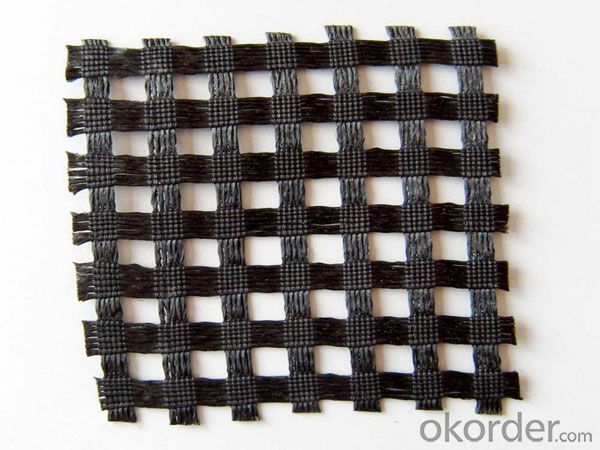

Structure of Bitumen Coated Fiberglass Geogrid:

Bitumen Coated Fiberglass Geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed.This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Main Features of Bitumen Coated Fiberglass Geogrid :

fiberglass geogrid for soil reinforcement

- Reinforcement of the surface of road and bridge.

High tensile strength, low elongation

Dyke reinforcement on soft ground for stress evenness,sedimentation adjustment,increase of stability and loading capacity of fundus;

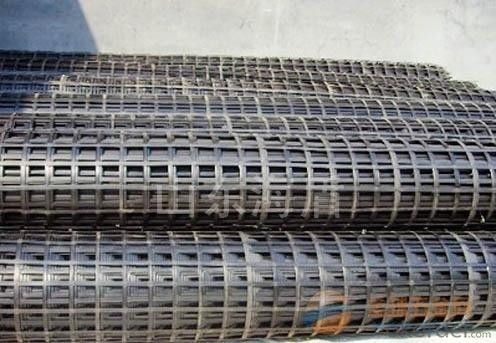

Bitumen Coated Fiberglass Geogrid Images

Bitumen Coated Fiberglass Geogrid Specification

Polyester Geogrid GGF80 Technical Specification | |||

Property | Test Method | Unit | Index |

Wide Width Tensile Strength | |||

MD | KN/M | ≥80 | |

CMD | KN/M | ≥80 | |

Elongation At Break | ≤4 | ||

Grid | MM | 25.4×25.4 | |

Width | M | 1~6 | |

Packaging | Details | ||

Roll Dimensions(W×L) | According to customer requirements | ||

Square Meters Per Roll | |||

Estimated Roll Weight | |||

It is widely used in Asphalt wall, railway foundation, dike slope, runway and sand harnessing.

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: Geotextiles for geotextiles - Specification for geotextiles

- 5Protective effect of 6. It has the following characteristics as non-woven geotextile has more than six functions, so it can be widely used in railway, highway, sports venues, dams, water conservancy construction, tunnel, coastal beach reclamation, environmental engineering,. The application of the field of water conservancy engineering geotextile: Seawall dyke Lake embankment projecttarget reservoir; reinforcement; reclamation project; flood control. Highway and railway port engineering: soft foundation reinforcement treatment; slope protection; pavement anti reflection crack structure layer; drainage system; green isolation belt. Electrical engineering: nuclear power plant foundation engineering; thermal power ash dam project; hydropower station project. Port and Waterway Engineering: the performance and application of the port geomembrane: the product has excellent filtration, drainage, isolation, reinforcement, protection. Can be widely used in railway, highway, water conservancy construction, sports hall, dam, tunnel, coastal beach, Ken, environmental protection, power plant, around the airport project.

- Q: How do geogrids help in reducing construction waste?

- Geogrids help in reducing construction waste by providing reinforcement and stabilization to soil, reducing the need for excessive excavation and material usage.

- Q: Can geogrids be used in reinforced soil slopes?

- Yes, geogrids can be used in reinforced soil slopes. Geogrids are commonly used in reinforced soil slopes to enhance stability and prevent slope erosion. They provide tensile strength to the soil, improving its load-bearing capacity and preventing slope failure.

- Q: How to apply the fixed scale of Geogrid

- Remove the geogrid as long as you take the reinforcement of things, such as U type nails, packing belt, gasket, steel nails and other reinforcement, and then roll up on it.

- Q: Can geogrids be used in soft soil conditions?

- Yes, geogrids can be used in soft soil conditions. Geogrids are often used in such conditions to improve the stability and load-bearing capacity of the soil. They are designed to provide reinforcement and prevent soil movement, making them an effective solution for soft soil conditions.

- Q: Can geogrids be used in retaining walls for highway sound barriers?

- Yes, geogrids can be used in retaining walls for highway sound barriers. Geogrids are often used in retaining walls to provide additional reinforcement and stability. They help distribute the load and improve the overall strength of the retaining wall. In the case of highway sound barriers, geogrids can be utilized to enhance the structural integrity of the wall while also reducing noise pollution.

- Q: How do geogrids improve soil reinforcement?

- Geogrids improve soil reinforcement by providing tensile strength and stability to the soil. They act as a reinforcement material, distributing the applied loads more evenly across the soil and preventing the soil from shifting or settling. This helps to enhance the overall stability and performance of the soil structure, making it more resistant to erosion, shear forces, and other types of geotechnical challenges.

- Q: What is the effect of aging on geogrid properties?

- The effect of aging on geogrid properties is generally a decrease in mechanical strength and stiffness. Over time, exposure to environmental factors such as sunlight, temperature variations, and moisture can cause degradation of the geogrid material, leading to reduced tensile strength, increased elongation, and diminished load-bearing capacity. The aging process can also result in changes to the geogrid's chemical composition and surface morphology, impacting its ability to interlock with surrounding soil particles and retain its original design characteristics. Therefore, it is crucial to consider the potential effects of aging when designing geogrid-based structures and to periodically assess their condition to ensure their long-term performance.

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth bridge abutments?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth bridge abutments. Geogrids are commonly used to enhance the stability and strength of soil structures, including bridge abutments. They provide lateral reinforcement, reduce settlement, and improve overall performance by distributing loads more evenly.

- Q: What is the effect of temperature on geogrid properties?

- The effect of temperature on geogrid properties can vary depending on the specific type of geogrid. In general, temperature can affect the mechanical properties of geogrids, such as tensile strength, stiffness, and creep behavior. Higher temperatures can soften the geogrid material, reducing its strength and stiffness. Conversely, lower temperatures can make the material more brittle. Therefore, it is important to consider the temperature conditions in which geogrids will be used to ensure their optimal performance and longevity.

Send your message to us

Tenax Biaxial Geogrids - Bitumen Coated Fiberglass Geogrid 100~100/kn for Roadbed Reinforce

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords