Geocells Material Fiberglass Geogrid 100KN/M for Road Bed

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid with 100KN/M for Road Bed

Description Of Fiberglass Geogrid with 100KN/M for Road Bed:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid with 100KN/M for Road Bed:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid with 100KN/M for Road Bed:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

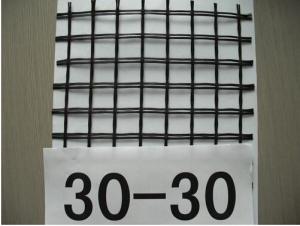

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with 100KN/M for Road Bed:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

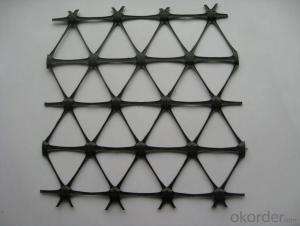

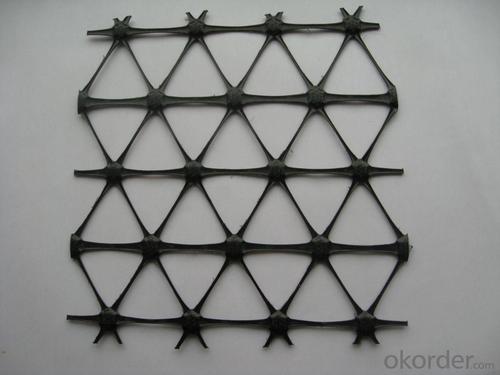

IMages of Fiberglass Geogrid with 100KN/M for Road Bed:

FAQ of Fiberglass Geogrid with 100KN/M for Road Bed:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can geogrids be used in railway ballast reinforcement applications?

- Yes, geogrids can be used in railway ballast reinforcement applications. Geogrids provide effective reinforcement to the ballast layer, increasing its strength and stability. By distributing loads more evenly, geogrids help to reduce settlement and deformation, improving the overall performance and longevity of the railway track.

- Q: The difference between polyester glass fiber cloth and glass geogrid

- Hello, this is two different products

- Q: How are geogrids manufactured?

- Geogrids are manufactured by extruding or weaving polymer materials such as polypropylene or polyester into a grid-like structure. This process involves melting the polymer, forming it into a grid pattern, and cooling it to create a strong and flexible geogrid.

- Q: Introduction of steel plastic grille

- By a single band,

- Q: How do geogrids improve the stability of landfills?

- Geogrids improve the stability of landfills by providing reinforcement to the soil layers. They act as a barrier to prevent the sliding and spreading of waste materials, increasing the overall strength and stability of the landfill. Additionally, geogrids help in distributing the load evenly, reducing the stress on the landfill walls and preventing potential failures or collapses.

- Q: What are the differences between geogrids and geosynthetic clay liners?

- Geogrids and geosynthetic clay liners (GCLs) are two different types of geosynthetics used in various civil engineering and environmental applications. Geogrids are typically made of high-strength polymer materials, such as polypropylene or polyester, and are designed to provide reinforcement and stabilization to soil structures. They have a grid-like structure with open apertures, allowing soil particles to interlock within the grid, improving load distribution and preventing soil erosion. Geogrids are commonly used in slope stabilization, retaining walls, and road construction. On the other hand, geosynthetic clay liners (GCLs) are composite materials consisting of a layer of bentonite clay sandwiched between two geotextile layers. Bentonite clay is highly absorbent and expands upon contact with water, creating a low permeability barrier. GCLs are primarily used as hydraulic barriers for containment applications, such as landfill liners, pond liners, and wastewater treatment facilities. They provide excellent resistance to liquid flow and act as a barrier to prevent the migration of contaminants. In summary, the main differences between geogrids and geosynthetic clay liners lie in their composition, purpose, and applications. Geogrids focus on soil reinforcement and stabilization, while GCLs are primarily used as barriers to control liquid flow and prevent the migration of contaminants.

- Q: What are the factors that affect the design and selection of geogrids for geosynthetic reinforcement of steep slopes?

- There are several factors that affect the design and selection of geogrids for geosynthetic reinforcement of steep slopes. These include the slope gradient, soil type, anticipated loadings, and project requirements. The geogrid's tensile strength, aperture size, and junction efficiency also play a crucial role in determining its suitability for the specific slope reinforcement application. Additionally, factors such as installation methods, durability, and cost-effectiveness are considered during the selection process. Overall, a comprehensive analysis of these factors ensures the appropriate design and selection of geogrids for effective and reliable geosynthetic reinforcement of steep slopes.

- Q: Are geogrids resistant to fire?

- No, geogrids are typically not resistant to fire.

- Q: Application and effect of steel plastic geogrid

- The general treatment of soft foundation filling height greater than 4 meters by.

- Q: Can geogrids be used in ground stabilization for water treatment plants?

- Yes, geogrids can be used in ground stabilization for water treatment plants. Geogrids are commonly utilized in the construction of retaining walls, slopes, and embankments to enhance stability and prevent erosion. In the case of water treatment plants, geogrids can be employed to reinforce the ground and provide additional support, ensuring long-term stability and preventing soil movement or failure.

Send your message to us

Geocells Material Fiberglass Geogrid 100KN/M for Road Bed

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords