Never Run Two-Way Geocells for Erosion Control Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Gangsu grille

Products overview:

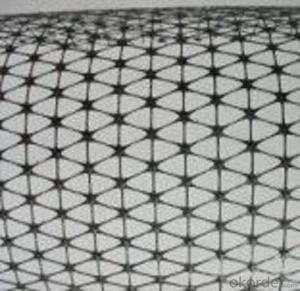

Shandong yongrun gangsu reinforced geogrid work by gangsu reinforcement with the new technology compound and into, as this product drawing and pressing the surface into a rough figure, the rules laid to fill in in soil have suffered huge resistance to stress and the filled soil and the friction between the whole, limits the foundation soil in the shear, a profile extrusion and uplift, because the stiffness of reinforced cushion is larger, the foundation of the load to spread and more evenly transfer, distribution to lie down on the soft soil, a good way to develop the bearing capacity of the foundation, because the function of the reinforced cushion layer, increase the range of compressible stratum foundation stiffness, be helpful for adjusting deformation of foundation, the use of the reinforced geogrid and the formation of steel model work of the reinforced composite pad to belong to flexible structures, can be very good to absorb the energy of the earthquake, so its seismic performance is good.

Product features:

1, strength, creep, have to adapt to all kinds of environmental soil, and can meet the high road and retaining wall. Use tall

2, can improve the efficiency of the reinforcement embedded lock, bite the load effect, great enhancement the bearing capacity of the foundation, effective constraint of soil lateral displacement of foundation, enhance solid performance.

3, and traditional grille has more strength than large load-carrying capacity and strong, corrosion, prevent ageing, friction coefficient, uniform pore, construction is convenient, service life is long, etc.

4, the more adapted to the deep sea operation, the bank reinforcement, fundamentally solve the other materials do because long stone cage by sea water erosion and cause of low strength and corrosion resistance performance is poor, use short life other technical problems. Product application can be used for highway, railway, embankment and abutment, construction the pavement, dock, bank revetments, prevent flood dike, DAMS and beaches management, freight and slag field, airport, playground, environmental protection construction, soft foundation improvement and retaining wall, slope protection and pavement of inferior civil engineering.

Packing specification:

GSZ30-30-GSZ150-150

- Q: Can geogrids be used in water drainage applications?

- Yes, geogrids can be used in water drainage applications. They are commonly used to reinforce and stabilize soil in drainage systems, such as retaining walls, culverts, and embankments. Geogrids help to prevent soil erosion and improve the overall drainage efficiency by providing structural support and reducing the risk of soil movement.

- Q: Are geogrids effective in stabilizing embankments for pipeline crossings?

- Yes, geogrids are effective in stabilizing embankments for pipeline crossings. Geogrids provide reinforcement and enhance the stability of the soil, reducing the risk of embankment failure. By distributing loads and increasing the bearing capacity of the soil, geogrids help to prevent settlement and movement, ensuring the long-term stability of the embankment for pipeline crossings.

- Q: How do geogrids help in reducing settlement of foundations?

- Geogrids help in reducing settlement of foundations by providing reinforcement and stability to the soil. They distribute the load more evenly, preventing differential settlement and soil consolidation. Additionally, geogrids increase the tensile strength of the soil, minimizing deformation and settlement over time.

- Q: I asked what the raw materials needed for the production were, for example, what the green mesh was made of

- Plastic geogrid with high strength steel wire (or other fiber), through special processing, and polyethylene (PE) or polypropylene (PP), and adding other additives by extrusion become composite high strength tensile band, and surface roughness is embossed, high strength reinforced Geotextile

- Q: Which instrument is used to measure the permeability of geotextiles?

- . The warp knitted composite geotextile is a new kind of geotextile material, which is made of glass fiber (or synthetic fiber) as the reinforcing material. The geotextile is a kind of impervious material, which is made of plastic film as impervious material and non-woven fabric. It is a kind of nonwoven and industrial cloth. It is a kind of polyester staple fiber, which is made of 6-12 denier denier fiber with a length of 54-64mm. Through the production of non-woven production equipment, carding, messy (short fiber intertwined with each other), laying nets (standardized entanglement fixation), acupuncture and other production processes are made of cloth

- Q: How do geogrids help in reducing the risk of soil liquefaction?

- Geogrids help in reducing the risk of soil liquefaction by reinforcing the soil and improving its stability. They provide additional strength and prevent the soil from losing its strength and becoming liquefied during earthquakes or other dynamic loading events.

- Q: What is the meaning of the geogrid check bond frequency 2%

- This bond is really not heard, you say is not the kind of sticky,

- Q: What is the minimum net size of geogrid mesh Center

- This depends on the material

- Q: Where is the best geogrid to do?

- Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid. Two way, single main look at the design, there are many domestic manufacturers of geotechnical materials, product quality depends on the order contract, to meet the national standards have a lot of. It's all about there.

- Q: What are the long-term effects of using geogrids?

- The long-term effects of using geogrids include improved soil stability and increased load-bearing capacity, reduced soil erosion and sedimentation, enhanced pavement performance, and prolonged lifespan of infrastructure projects. Additionally, geogrids can contribute to cost savings through reduced maintenance and repair needs.

Send your message to us

Never Run Two-Way Geocells for Erosion Control Geogrid

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords