Self-Adhesive Bitumen Coated Fiberglass Geogrid Geocells for Driveways

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid with Self-adhesive Bitumen Coated

Description Of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and

then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly

improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving

difficulties of strengthening the bituminous pavement.

Main Features of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

1. Light weight, high tensile strength, high modulus, low elongation and good toughness.

2. Corrosion resistance, no long-term creep, long life span.

3. Good physical and chemical stability and good thermal stability.

4. Resistant to fatigue cracking, high-temperature track and low temperature shrinkage cracking.

5. Delaying and decreasing crack reflection.

Specifications of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

1. Maintenance of old asphalt road reinforcement of asphalt pavement.

2. Converting old cement concrete road into composite road.

3. Restraining reflection cracking caused by block shrinkage.

4. Preventing and controlling the cracking caused by new and old combination and uneven settlement.

5. Road extension.

6. Reinforcement of soft soil foundation and overall strength of roadbed.

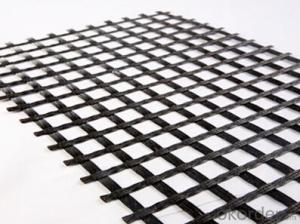

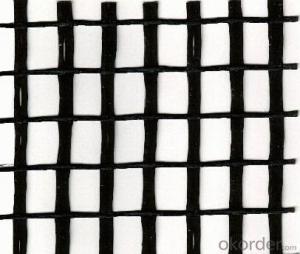

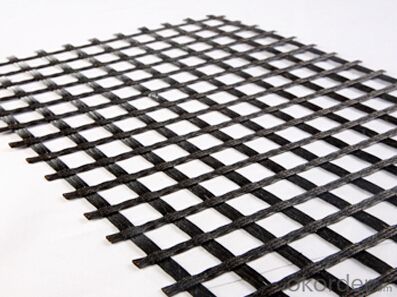

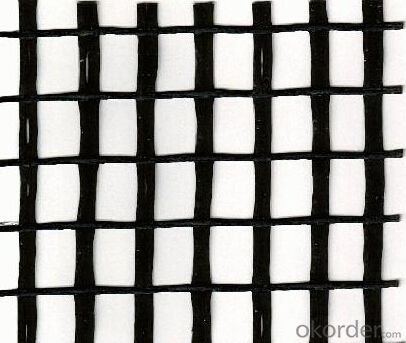

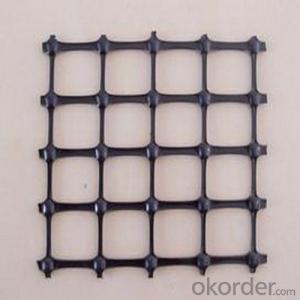

IMages of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

FAQ of Fiberglass Geogrid with Self-adhesive Bitumen Coated:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What is the role of geogrid?

- Unidirectional geogrid reinforcement for River seawall: made of stone cage, with the grid and use, prevent the dam washed collapse, stone cage is permeable and can reduce the impact of the waves, prolong the life of the dam, save manpower, shorten the construction period. The geogrid reinforcement material constitutive model

- Q: Should the municipal geogrid be included in the area of overlap, and, if necessary, the proportion of the area to be included?

- The measurement of municipal geogrid shall not be included in the overlap area

- Q: Who knows how much the staggered distance of the lap joint of the geogrid is?

- The staggered distance of the lap joint shall not be less than 300 mm. Specific specification (geotextile lap laying)

- Q: Can geogrids be used in temporary construction platforms for heavy equipment?

- Yes, geogrids can be used in temporary construction platforms for heavy equipment. Geogrids are strong and durable, providing stability and reinforcement to the ground. They can distribute the weight of heavy equipment, prevent soil erosion, and improve load-bearing capacity, making them suitable for temporary construction platforms.

- Q: How do geogrids help in reducing soil settlement?

- Geogrids help in reducing soil settlement by providing reinforcement to the soil structure, which helps distribute the load more evenly and prevent excessive settlement. They act as a stabilizing element by increasing the tensile strength of the soil, preventing its movement and settling.

- Q: What are the specifications of fiberglass geogrid for Asphalt Pavement

- The use of asphalt pavement can only use fiberglass grille, the other are used on the top of the embankment

- Q: How do geogrids improve the performance of geocell-reinforced retaining walls?

- Geogrids improve the performance of geocell-reinforced retaining walls by providing additional reinforcement and stability to the structure. They help distribute the loads more evenly, reducing the pressure on the retaining wall and preventing excessive deformation. Geogrids also increase the overall strength and durability of the wall, enhancing its ability to withstand lateral forces and maintain its shape over time.

- Q: What are the criteria for Geogrid?Would like to know the price of Geogrid and geogrid manufacturers

- And then under the heating conditions of directional drawing. The unidirectional stretching grid is only drawn along the length direction of the plate, and the bidirectional stretching grid is made by stretching the unidirectional stretching grid in the direction perpendicular to the length.

- Q: What are the technical parameters and testing standards of the tensile creep testing machine

- Technical parameters: 1 180KN; the maximum load: 2 load accuracy: less than 1%; 3 fixture width 50mm and 200mm optional; 4 effective creep space

- Q: Are geogrids suitable for reinforcement of soft subgrades?

- Yes, geogrids are suitable for reinforcement of soft subgrades. Geogrids have been proven to effectively improve stability and strength in soft subgrade soils by distributing loads and reducing settlement. They provide additional tensile strength, preventing excessive deformation and enhancing the overall performance of the subgrade.

Send your message to us

Self-Adhesive Bitumen Coated Fiberglass Geogrid Geocells for Driveways

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords